Buckingham Park Water District Tracer Study Results and Analysis

A tracer study conducted at Buckingham Park Water District evaluated the efficiency of tank baffling to prevent short-circuiting. The study revealed a baffling factor of 0.14, similar to the initial study. Repairs were made to improve baffling, but the cause of the low factor remains unknown. Further investigations and inspections are needed to understand and rectify the issue.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

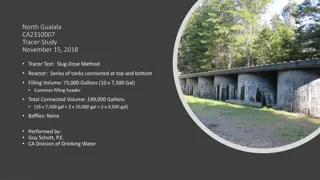

Buckingham Park Water District Tracer Study #2 2/2/17 By Karen Stufkosky

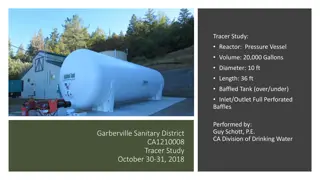

Background and Purpose This tracer study is the second tracer study done for this tank since its installation. The first study (2/10/16) provided a lower baffling factor (0.13) than expected. Upon investigation, the tank appeared to be short-circuiting from observation of the sediment on the bottom of the tank. The tank was dove in September 2016 for its one-year, post-construction inspection. The divers photograph a gap between the curtain and the tank bottom and side wall. The divers filled in the gaps with NSF approved Aquatapoxy to potentially decrease any short-circuiting. This second study (2/2/17) was performed to determine if the baffling factor had improved with the above mentioned repairs.

Tracer Study #1 Results Study 2/10/16 time min 0 15 30 45 60 75 90 105 120 130 140 Tracer mg/L 0 0.019 0.125 0.177 0.27 0.322 0.398 0.407 0.592 0.598 0.639 Operating Tank Level: 31.8 ft. t/T 0.00 0.02 0.03 0.05 0.07 0.09 0.10 0.12 0.14 0.15 0.16 Baffling Factor: 0.13 Dosage: 4.6 Flow (inlet/outlet): 200 gpm; HRT: 867 minutes (14.4 hrs)

Tracer Study #2 Results Study 2/2/17 Time (min) 0 30 60 70 80 90 100 110 120 130 140 160 180 Tracer F (mg/L) 0.00 0.04 0.18 0.17 0.17 0.21 0.27 0.31 0.33 0.33 0.31 0.34 0.40 Operating Tank Level: 33.0-33.8 ft. t/T 0.00 0.03 0.07 0.08 0.09 0.10 0.11 0.13 0.14 0.15 0.16 0.18 0.21 Measured Dose: 3.3 mg/L F Flow: average 203 gpm HRT: 871 minutes (14.5 hrs) Baffling Factor: 0.14

Results The results of this study gave a baffling factor of 0.14, similar to the first study with a 0.13 baffling factor. The cause for the low baffling factor is unknown. The epoxy applied to the baffling current may have broken loose. Unknown flow pattern (investigate with NSF dye in tank or a Computational Fluid Dynamics software) As-built drawings were reviewed to ensure the tank is not being by-passed. There is no piping or valving that allows the tank to be by-passed, ruling out any short-circuiting or cross-connections.

Conclusions The results of this tracer study gave a baffling factor of 0.14 for this tank. Repairs to the current wall were expected to increase the baffling factor and prevent short-circuiting. The tank should be inspected again to ensure the epoxy is still in place. The tank flow patterns should be further investigated through a study with dye and through flow modeling software. List of NSF 61 approved dyes: http://info.nsf.org/Certified/PwsChemicals/Listings.asp?CompanyName=& TradeName=&ChemicalName=&ProductFunction=Tracer+Dye&PlantState= &PlantCountry=&PlantRegion=

200K Clearwell 30-ft Diameter; 37.8 ft. Baffle Height

2 ft opening Outlet Outlet Flush 18-in opening, 6-in pipe Inlet Diameter: 30 ft Baffle Ht: 37.8 ft Nozzle Velocity: 5.1 ft/sec Inlet Riser 12 ft ht, 6" x 4" Reducer

Nozzle Velocity: 5.1 ft/sec Baffle Curtain Inlet Riser 12 ft Ht. 6 x 4 Reducer