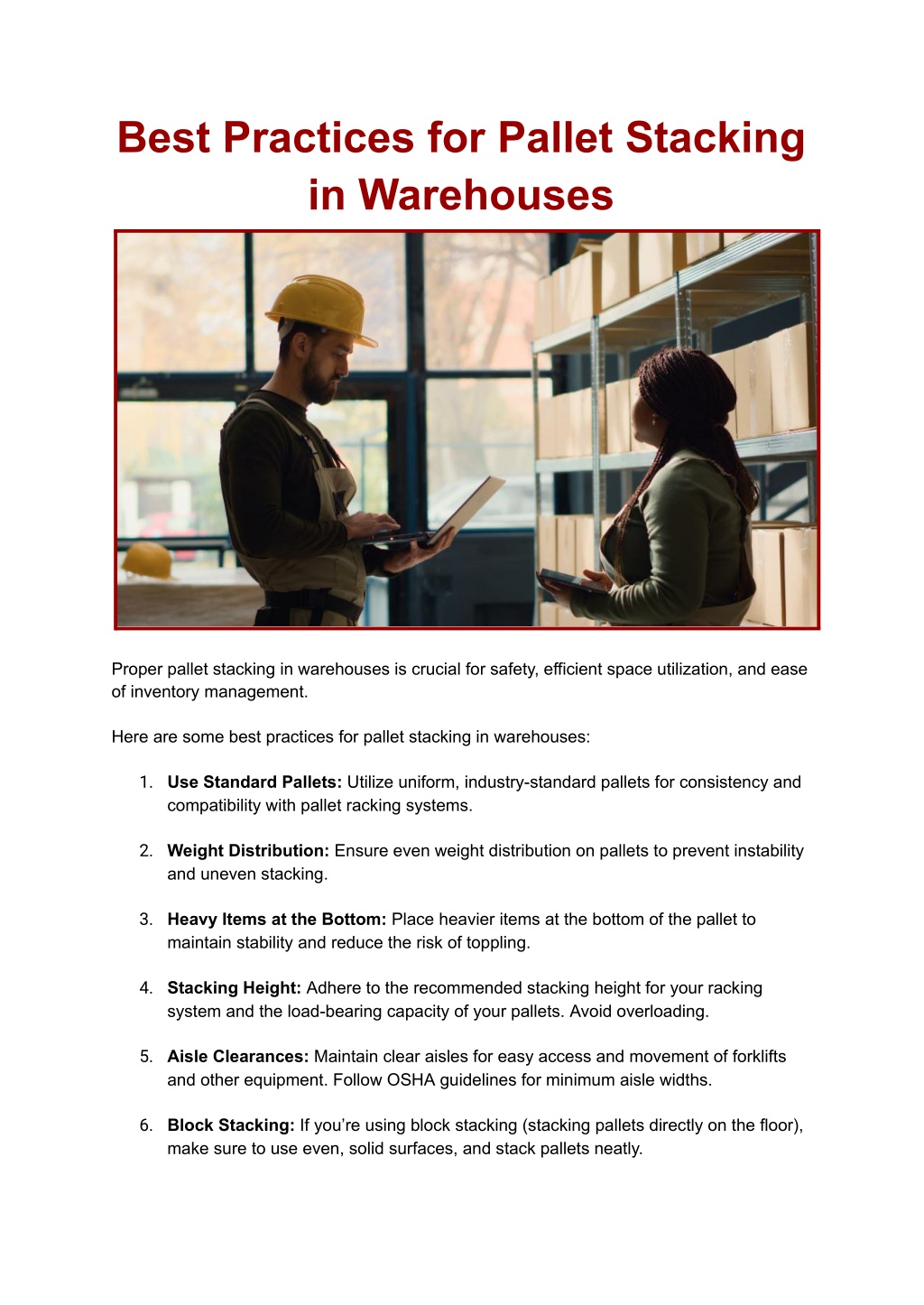

Best Practices for Pallet Stacking in Warehouses

Proper pallet stacking in warehouses is crucial for safety, efficient space utilization, and ease of inventory management. Here are some best practices for pallet stacking in warehouses:nn//seerackinginspections.medium.com/best-practices-for-pallet-stacking-in-warehouses-356bcbdc6532

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

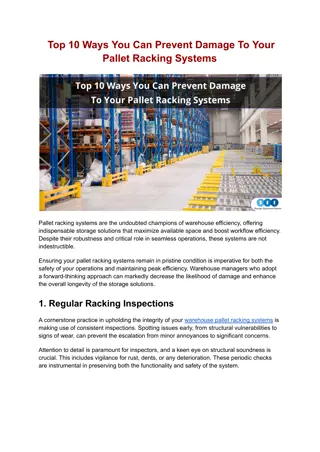

Best Practices for Pallet Stacking in Warehouses Proper pallet stacking in warehouses is crucial for safety, efficient space utilization, and ease of inventory management. Here are some best practices for pallet stacking in warehouses: 1. Use Standard Pallets: Utilize uniform, industry-standard pallets for consistency and compatibility with pallet racking systems. 2. Weight Distribution: Ensure even weight distribution on pallets to prevent instability and uneven stacking. 3. Heavy Items at the Bottom: Place heavier items at the bottom of the pallet to maintain stability and reduce the risk of toppling. 4. Stacking Height: Adhere to the recommended stacking height for your racking system and the load-bearing capacity of your pallets. Avoid overloading. 5. Aisle Clearances: Maintain clear aisles for easy access and movement of forklifts and other equipment. Follow OSHA guidelines for minimum aisle widths. 6. Block Stacking: If you re using block stacking (stacking pallets directly on the floor), make sure to use even, solid surfaces, and stack pallets neatly.

7. Pallet Overhang: Avoid pallet overhang, as it can make stacks unstable and create safety hazards. 8. Use Stretch Wrap or Banding: Secure pallet loads with stretch wrap or banding to prevent shifting during transport or storage. 9. Stack Like Items Together: Group similar products together for easier access and inventory management. 10. Labeling: Clearly label each pallet with product information, lot numbers, and other relevant details for easy identification. 11. Consider Stackable and Nestable Pallets: Stackable pallets are designed to be safely stacked, while nestable pallets save space when empty. 12. Inspect Pallets: Regularly inspect pallets for damage and replace any broken or damaged ones promptly. 13. Space Optimization: Plan your pallet stacking to maximize the use of available space within your warehouse. Use pallet rack systems efficiently. 14. Safety Training: Ensure that your staff is trained in safe stacking practices and proper use of forklifts and pallet jacks. 15. Pallet Rack Systems: If using pallet rack systems, follow the manufacturer s guidelines for assembly, maintenance, and load capacity. 16. Rack Safety Accessories: Install safety accessories such as rack guards, upright protectors, and aisle signage to enhance safety. 17. Keep Emergency Exits Clear: Do not block emergency exits or fire safety equipment with pallets. 18. Regular Maintenance: Conduct routine maintenance on your pallet racking systems to identify and address any issues promptly. 19. Record Keeping: Maintain records of pallet storage configurations, load weights, and stacking patterns for reference and safety auditing. Remember that safety should always be a top priority. Proper pallet stacking not only enhances efficiency but also reduces the risk of accidents and product damage. Additionally, compliance with local regulations and industry standards is essential to ensure the safety of your warehouse operations. Original Blog - https://seerackinginspections.medium.com/best-practices-for-pallet-stacking-in-warehouses- 356bcbdc6532