Advancements in Lepton Colliders Technology

Emanuela Barzi and co-authors have made significant progress in developing lepton colliders with higher gradients at lower capital and operational costs. Their research focuses on using Superconducting Nb3Sn coated Cu RF cavities, parallel-feed RF structures, and innovative technologies to achieve higher efficiencies and gradients in accelerator systems. By fostering R&D in these advanced tools, the Particle Physics community aims to make future lepton colliders more affordable and feasible for construction, potentially revolutionizing the field of High Energy Physics.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Lepton Colliders with Higher Gradient at Lower Capital and Operational Costs Emanuela Barzi, Fermilab & Ohio State University

Co-authors California Institute of Technology: Barry Barish Thomas Jefferson National Accelerator Facility: Robert A. Rimmer, Anne-Marie Valente-Feliciano Massachusetts Institute of Technology: Bill Barletta SLAC National Accelerator Laboratory: Marc Ross, Paul B. Welander, Emilio Nanni, Sami Tantawi, Mamdouh Nasr, Mitch Schneider Los Alamos National Laboratory: Evgenya Simakov, Igor Usov Energy to Power Solutions (e2P): Chris Rey Technische Universit t Darmstadt, Germany: Lambert Alff, Nail Karabas, M rton Major, Jasnamol P. Palakkal, Stefan Petzold, Norbert Pietralla, Nils Sch fer National Institute for Materials Science, Japan: Akihiro Kikuchi High Energy Accelerator Research Organization (KEK), Japan: Hitoshi Hayano, Hayato Ito, Kensei Umemori, T. Kubo, Hideaki Monjushiro Tohoku University, Japan: Shigeru Kashiwagi, H. Hama Kyushu University, Japan: Fuminori Honda Akita Kagaku Co., Ltd., Japan: K. Takahashi, R. Takahashi Akita Industrial Technology Center, Japan: Y. Kondo, K. Yamakawa Iwate Industry Promotion Center, Japan: K. Kon

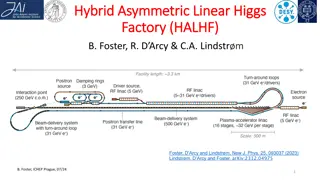

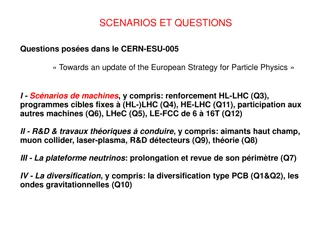

Premise Progress since Snowmass 2013 After the 2003 ITRP recommendation to focus on Superconducting RF, in the last decade the technology in Normal-Conducting RF has made considerable progress. C3, which uses parallel-feed RF structures, enable both higher accelerating gradients and higher efficiencies and achieves linac gradients exceeding 100 MV/m with cryo-cooled Cu. Superconducting Nb3Sn coated RF cavities are expected to achieve 100 MV/m too, plus a Q030 times that of Nb. Nb3Sn coated cavities can be operated at 4.5 K rather than in superfluid helium. Heavily processed bulk Nb cavities are a main cost driver, whereas Cu or bronze are less expensive and much more thermally efficient metals. There are small R&D efforts in the U.S. and abroad, including at CERN, in producing Nb3Sn films on either Cu or bronze. Parallel-feed RF structures are applicable to both Cu and Nb3Sn coated Cu cells.

Baseline Design/Layout and Parameters Based on the assessment of current efforts in the U.S. on the novel concept of parallel- feed RF accelerator structures, and in the U.S. and abroad in producing Nb3Sn films on either Cu or bronze, we recommend that the Particle Physics community foster R&D in Superconducting Nb3Sn coated Cu RF Cavities instead of costly bulk Nb, while pursuing in parallel the novel U.S. concept of parallel-feed RF accelerator structures made of Cu or Cu alloys. A technology that synergistically uses both of these advanced tools would make an ILC or equivalent machines more affordable and more likely to be built. A devoted global effort in developing Cu cavity structures coated with Nb3Sn would readily apply to other HEP accelerators, for instance a Muon Collider, and to accelerators beyond HEP. A machine whose RF structures are made of bulk Cu or bronze that operate with the properties of Nb3Sn would deliver higher gradient and higher temperature of operation and reduce the overall capital and operational costs of any future lepton collider below and above 1 TeV cm.

Key Technologies (1) Coating Cu/bronze inner surface with thin layer of Nb3Sn White paper at https://arxiv.org/ftp/arxiv/papers/2203/2203.09718.pdf Electroplating FNAL, KEK, Akita Kagaku Co. Ltd., Tohoku University,Akita Industrial Technology Center. Magnetron sputtering in co-sputtering mode from two targets with direct deposition stoichiometric Nb3Sn Darmstadt. Magnetron sputtering from a single stoichiometric target CERN, Old Dominion University Multilayer sequential magnetron sputtering - Old Dominion University, LANL The Bronze Route, which superconducting wire technology and also exploits the heat treatment temperature reduction effect of the Cu as ternary element of the Nb-Sn-Cu phase diagram NIMS. on substrate Universit t of - Technische builds upon Nb3Sn Schematic of magnetron sputtering setup with two targets at Technische Universit t Darmstadt.

Key Technologies (2) Parallel-feed RF accelerator structures C3is NCRF accelerator technology to operate at high gradient with high RF-to-beam efficiency. Use highly-optimized reentrant cells with distributed coupling to power the linac without cell-to-cell RF coupling and operate at 77 K Structure is machined in two halves by low-cost numerically-controlled milling machining process produces ultra-high vacuum quality surfaces that need no further machining before a standard Cu surface etch. This manufacturing technique provides an ideal Cu surface to be coated with superconducting films, as it allows complete access to the inner cavity surface for the coating process. The system is then assembled simply by joining the two blocks. machines. This

Other Parameters Accelerator design and challenges Civil Engineering and site Sustainability and Carbon footprint studies Proposals for upgrades and extensions Stageability to future experiments Depend on Lepton machine considered

State of Proposal and R&D needs (5-10 years) Under reasonable funding in the U.S. with respect to now, perform R&D in Superconducting Nb3Sn coated Cu RF Cavities instead of on costly bulk Nb. Use the next decade for R&D on producing Nb3Sn on inexpensive and thermally efficient metals such as Cu or bronze, while pursuing in parallel the novel U.S. concept of parallel-feed RF accelerator structures. Increased effort on these two techniques would synergize expenditures towards which will naturally converge to a clear decision by the community on which path to take for the RF of an ILC. Use SLAC existing and future test setups for single cavity tests first, and meter scale next. That would lead to a decision to proceed with cryomodule design. Cryomodules to be tested at SLAC Demo or at FAST. Use SLAC Demo setup to test components from industry as they scale up in 2030-2034. 2028 CDR 10-year progress, 2030-2034 Industrialization

Conclusions A devoted global effort in developing Cu cavity structures coated with Nb3Sn would make the ILC or Higgs/EW factories more affordable and more likely to be built. Using the next decade for R&D on producing Nb3Sn on inexpensive and thermally efficient metals such as Cu or bronze, while pursuing in parallel the novel U.S. concept of parallel-feed RF accelerator structures, would compound the best of both worlds. Not only do parallel-feed RF structures enable both higher accelerating gradients and higher efficiencies, but they would be applicable to both Cu and Nb3Sn coated Cu cells. Increased effort on these two techniques would synergize expenditures towards 10-year progress, which will naturally converge to a clear decision by the community on which path to take for the RF of an ILC or other leptonic future accelerator. If for any reason, the C3structures were not ready in ten years, the current methods of Nb3Sn coatings on Cu or bronze are geared towards standard cavity cells. Were one of these methods to succeed, it could still be implemented on conventional Cu RFs. In conclusion, the use of distributed coupling structure topology within improved performance parameters together with Nb3Sn coating technology can lead to a paradigm shift for superconducting linacs, with higher gradient, higher temperature of operation, and reduced overall costs for any future collider.