Introduction to Kinematics and Dynamics of Machines in Industrial Engineering Department

This chapter introduces the mechanisms and machines in industrial engineering focusing on the kinematics and dynamics of machines. The concept of slider-crank mechanisms and their inversions are explored, providing applications such as reciprocating engines, rotary engines, and hand pumps. Additiona

2 views • 19 slides

The Art of Clip Crank Fabrication

In the intricate world of machines, there exists a hidden hero \u2013 the clip crank mechanism. Ever wondered how engines purr smoothly or how machines execute their precise movements?

0 views • 4 slides

Balancing of Reciprocating Masses in Engines

Learn about the balancing of reciprocating masses in engines, including the importance of balancing primary and secondary forces in multi-cylinder in-line engines. Discover how crank angles and cylinder arrangements contribute to balancing forces for optimal engine performance.

0 views • 6 slides

Slider Crank Mechanism: Practice Problems and Solutions

Explore a practice problem based on a slider crank mechanism, involving calculations for velocity of the slider, velocity of a point on the connecting rod, and angular velocity. Detailed steps and solutions provided to understand the concepts clearly.

4 views • 6 slides

Kinematics of Machines: Instantaneous Center Method for Velocity and Acceleration Analysis

Explore the method of locating instantaneous centers in mechanisms to analyze velocity and acceleration. The content covers examples of pin-jointed four-bar mechanisms and slider-crank mechanisms, providing dimensions and angular velocities calculations. Prof. Divyesh B. Patel from L.E. College, Mor

1 views • 13 slides

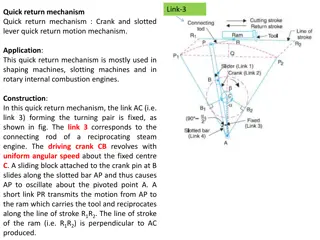

Quick Return Mechanism in Machinery

Exploring the application, construction, and velocity analysis of the crank and slotted lever quick return motion mechanism commonly used in shaping machines, slotting machines, and rotary internal combustion engines. The mechanism involves fixed link AC, driving crank CB, sliding block, and short l

8 views • 14 slides

Acceleration Analysis of Slider Crank Mechanism

In this analysis, we calculate the acceleration of the slider at point B, acceleration of point E, and the angular acceleration of the link AB in a slider crank mechanism. The steps involve drawing configuration, velocity, and acceleration diagrams with suitable scales to determine the necessary par

0 views • 12 slides

Graphical Method for Velocity Analysis of Planar Mechanisms

Learn about the graphical method for velocity analysis of planar mechanisms through practice problems involving slider-crank mechanisms and link velocities. Understand how to calculate slider velocity, point velocity, and angular velocities using the given dimensions and rotational speeds. Visualize

0 views • 6 slides

The Scotch Yoke Mechanism: Experiment and Analysis

The Scotch Yoke Mechanism is a slider-crank mechanism that converts linear motion into rotational motion or vice versa. This experiment involves studying the velocity, acceleration, and displacement of a slider as the crank is rotated with constant angular velocity in a slotted link slider-crank mec

1 views • 5 slides

Basic Engine Operation Principles

Explore the physical principles related to engine operation, energy conversion, and the basic parts of a gasoline engine assembly. Learn about atmospheric pressure, vacuum, temperature-pressure-volume relationship, states of matter, and how engines and motors convert energy. Dive into the components

0 views • 37 slides

Analysis of Slider-Crank Mechanism and Experimental Data

Slider-crank mechanism analysis involves understanding the transformation of input motion into desired output motion. This mechanism consists of a crank, coupler, slider, and ground link, converting circular motion into linear motion. Experimental procedures involve setting crank angles and recordin

0 views • 6 slides

Introduction to Press Tools and Presses Classification

Press tools are specialized tooling used for various forming processes like blanking, piercing, shearing, bending, drawing, and more. Presses are classified based on power source, frame type, slide actuation method, and number of slides. Mechanical and hydraulic presses are distinguished by power so

1 views • 20 slides

Prototype Showcase: Metal 3D Printer Demo and Skateboard Truck Designs

Explore a prototype showcase featuring a metal 3D printer demo and intricate skateboard truck and bike crank designs. Learn about the manufacturing processes used, team responsibilities, and plans for iteration based on feedback. Get insights into model positioning, topology optimization, and scalin

0 views • 7 slides