The Art of Clip Crank Fabrication

In the intricate world of machines, there exists a hidden hero u2013 the clip crank mechanism. Ever wondered how engines purr smoothly or how machines execute their precise movements?

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

The Art of Clip Crank Fabrication Clip Crank Fabrication: The Backbone of Mechanical Systems In the intricate world of machines, there exists a hidden hero the clip crank mechanism. Ever wondered how engines purr smoothly or how machines execute their precise movements? Look no further than the art of clip crank fabrication a blend of craftsmanship and science that brings these crucial components to life. Let's embark on a journey through the realm of Clip Crank fabrication, exploring its essence, processes, and significance.

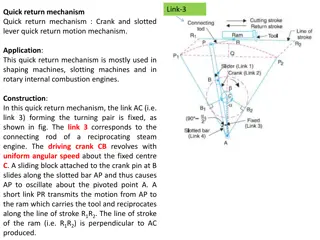

Understanding Clip Crank Mechanisms At its essence, a clip crank mechanism is the beating heart of many mechanical systems. Picture a crankshaft adorned with clips or arms, diligently converting rotational motion into linear motion, or vice versa. Here's a breakdown of its fundamental components: Crankshaft: The central rotating shaft orchestrating the motion. Clips or Arms: Affixed to the crankshaft, facilitating seamless motion transfer. Connecting Rods: Linking the clips or arms to the driven part, ensuring fluid motion. Bearings: Providing frictionless rotation, essential for smooth operation. The Craft of Fabrication Clip crank fabrication is a meticulous dance of design, precision machining, and stringent quality control. Let's delve into the process: 1. Design and Planning The journey begins with a vision. Engineers and designers meticulously craft blueprints and 3D models, considering every nuance and requirement. Material selection and dimensioning take center stage in this phase. 2. Material Selection Choosing the right material is paramount for durability and performance. Whether it's the robustness of steel or the lightweight versatility of aluminum, each material is chosen with care, ensuring it meets the demands of the application. 3. Machining Precision machining breathes life into the design. Through techniques like milling and turning, each component is sculpted with utmost precision, ensuring a perfect fit and functionality. 4. Assembly Like pieces of a puzzle coming together, each component is meticulously assembled to form the complete mechanism. Attention to detail is paramount, ensuring seamless operation and performance. 5. Testing and Quality Control Before the clip crank sees the light of day, it undergoes rigorous testing. Every aspect is scrutinized to ensure it meets the highest standards of quality and performance, free from defects or discrepancies.

6. Finishing The final touch coating, painting, or anodizing not only enhances aesthetics but also shields against corrosion, ensuring longevity and resilience. The Significance of Clip Crank Fabrication Clip crank fabrication is the backbone of mechanical systems, offering precision, efficiency, and reliability. Here's why it's indispensable: 1. Precision and Efficiency: Clip cranks are designed to operate with utmost precision, ensuring seamless motion transfer and reducing wear and tear in mechanical systems. 2. Durability: Through meticulous fabrication processes and high-quality materials, clip cranks boast durability, withstanding the rigors of heavy usage and harsh conditions. 3. Versatility: From automotive engines to industrial machinery, clip cranks find application across various sectors, underscoring their versatility and adaptability. 4. Cost-Effectiveness: Investing in high-quality clip crank fabrication translates to long-term cost savings, minimizing maintenance needs and extending the lifespan of machinery. Applications and Innovations Clip crank mechanisms find application across diverse industries, including automotive, industrial, aerospace, and robotics. Furthermore, advancements in technology have ushered in innovations in clip crank fabrication: CNC Machining: Computer Numerical Control (CNC) machining ensures unparalleled precision and consistency, revolutionizing clip crank fabrication. Additive Manufacturing: 3D printing opens new frontiers in clip crank fabrication, allowing for intricate geometries and reduced production times. Advanced Materials: High-strength alloys and composites enhance the performance and durability of clip cranks, catering to demanding applications. Surface Treatments: Innovative coatings and treatments bolster the properties of clip cranks, enhancing hardness, reducing friction, and extending lifespan. In Conclusion Clip Crank Fabrication is not just a manufacturing process it's the cornerstone of modern mechanical systems. By embracing precision, craftsmanship, and innovation, clip crank fabrication ensures the seamless operation and longevity of machinery and equipment across various industries. As we stride into the future, the possibilities in clip crank

fabrication hold promise for even greater efficiency, precision, and durability, driving innovation and progress in mechanical engineering. Also Read: Roller, Weldment and Shaft Assy Manufacturer and Supplier