Supplier Onsite Assessments for Food Safety Compliance

Conducting onsite assessments at food suppliers producing ice cream products, RTE nuts, and RTE spinach dairy dip reveals critical findings related to process control, equipment maintenance, environmental monitoring, and microbial hazards. The assessments highlight gaps in HACCP design/validation, extraneous material control, EMP implementation, and sanitation practices, emphasizing the importance of comprehensive risk mitigation strategies in ensuring food safety compliance.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

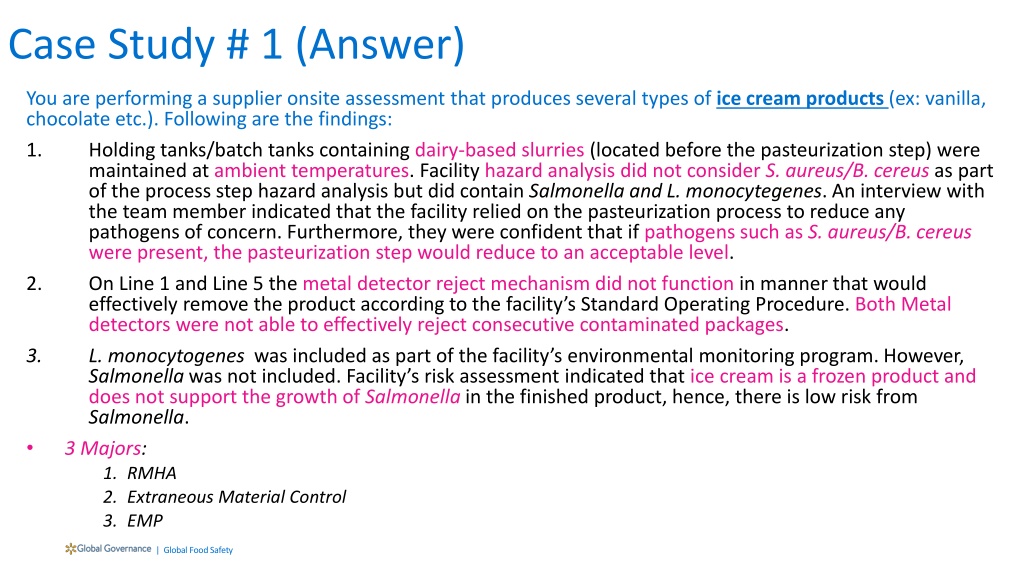

Case Study # 1 (Answer) You are performing a supplier onsite assessment that produces several types of ice cream products (ex: vanilla, chocolate etc.). Following are the findings: 1. Holding tanks/batch tanks containing dairy-based slurries (located before the pasteurization step) were maintained at ambient temperatures. Facility hazard analysis did not consider S. aureus/B. cereus as part of the process step hazard analysis but did contain Salmonella and L. monocytegenes. An interview with the team member indicated that the facility relied on the pasteurization process to reduce any pathogens of concern. Furthermore, they were confident that if pathogens such as S. aureus/B. cereus were present, the pasteurization step would reduce to an acceptable level. 2. On Line 1 and Line 5 the metal detector reject mechanism did not function in manner that would effectively remove the product according to the facility s Standard Operating Procedure. Both Metal detectors were not able to effectively reject consecutive contaminated packages. 3. L. monocytogenes was included as part of the facility s environmental monitoring program. However, Salmonellawas not included. Facility s risk assessment indicated that ice cream is a frozen product and does not support the growth of Salmonella in the finished product, hence, there is low risk from Salmonella. 3 Majors: 1. RMHA 2. Extraneous Material Control 3. EMP | Global Food Safety

Case Study # 2 (Answer) You are performing a supplier onsite assessment that produces several types of RTE nuts and nut products (ex: roasted almonds, pistachios, cashew, peanuts, walnuts etc.). Following are the findings: 1. You observed the oil roasting CCP process for almonds however, the facility roasts other nut products which you were not able to see (i.e., peanuts, pistachios, cashews). You ask for the roaster validations regarding these different nut products and receive one for almonds. The facility did not validate the other nut products based on the almond roast microbial lethality results. 2. Environmental monitoring is performed (drains, floors, non-food contact surfaces) for indicator microorganisms (ex: APC, Coliforms). The air for the cooling section of the roaster (blown air) comes from the roasting room. The blower has no filter. 3. Food grade lubricant is not used in any equipment. According to the Maintenance Manager, a detailed risk assessment was performed and as a conclusion there was not detected a contamination risk in any equipment. 4. Cooked (RTE) peanuts in super sacks were noted stored on the bottom of the steel racks in the warehouse. Raw peanuts waiting to be roasted are stored in the upper levels of the racks in the warehouse. Empty super sacks used to store raw and in-process RTE peanuts were noted stored intermingled on pallets along the south side of the warehouse 4 Majors: 1. HACCP Design/Validation (Can be Critical if appropriate justification is not available to prove that the facility is producing safe food despite lack of validations) 2. EMP 3. Extraneous Material Control / Chemical 4. Sanitation Control | Global Food Safety

Case Study # 3 (Answer) You are performing a supplier onsite assessment that produces RTE Spinach dairy dip. Following are the findings: 1. During time on the floor, you observed manual hand delivery and mixing of spinach at the centrifuge step of the process. Upon review of the hazard analysis, pathogens of concern due to manual handling (i.e., Staphylococcus aureus) were not identified. 2. This RTE product does not go through a thermal process. Pathogens of concern identified in the hazard analysis were stated to be controlled by maintaining critical refrigeration temperatures. The facility s justification for their critical temperature limits came from citing the widely used Tompkins letter however, this study was for meat products. 3. Adjacent to the RTE Spinach dairy dip processing area there is also a dedicated line to produce roasted nuts and tree nuts (this line does not produce products for WMT). Employees go back and forth between these two areas due to 2 reasons: (1) Limited employee resources and (2) Sanitation is performed at the same time in both rooms (3) Few raw materials are common to both type of product categories. There is no official record of training on allergen mitigation strategies or sanitation protocols. 2 Majors: 1 & 2 HACCP Design/Validation 3. Allergen Controls | Global Food Safety

Case Study # 4 (Answer) You are performing a supplier onsite assessment that produces several bakery products (bread rolls, croissants, bagels etc). Following are the findings: 1. A review of EMP program records showed that 16 out 65 swabs collected between the period June 22, 2022 and June 28th, 2022 were positive for Listeria spp (Locations: drains, floors, exterior legs of the equipment). Following cleaning and sanitation, corrective action swabs were taken. A review of records showed that Listeria spp. was not detected on the exterior legs of the equipment but were detected again in drains and floors (previously described). No documented corrective actions were available to indicate mitigation of the issue. 2. Facility also manufactures a variety of bakery products (for a customer other than WMT) that contain one or more major allergenic ingredients including wheat, milk, eggs, tree nuts (e.g., pecan pieces and pistachios), peanuts, and soy. This line is adjacent to the line that produces WMT products (which do not contain allergen). Facility s process step hazard analysis did not consider the risk of undeclared allergens in WMT finished product from the adjacent processing line that uses allergens in production. At the time of assessment, no documentation was made available to determine if the allergen controls are effective in minimizing the risk of undeclared allergens. 3 Majors 1. EMP 2. HACCP Design/ Validation or Allergen controls (2 Majors) | Global Food Safety

Case Study # 5 (Answer) You are performing a site assessment in a ready- to - cook Pizza operation. Following are the findings: 1. Raw material hazard analysis has been performed however facility control measures are considered as a factor in reducing the likelihood of occurrence. Thus, facility is unable to identify which of the control points are critical for food safety as per Codex HACCP guidance. 2. Raw ingredients are grouped in general categories such as IQF vegetables without consideration of hazards specific to individual ingredients. Categorization of risks are based on the general supplier approval program as a preventive control. 1 Major (for both findings): HACCP Design/Validation or RMHA | Global Food Safety

Case study #6 (Answer) An on-site assessment of an aerosol whipped cream facility. Following are the findings: 1. You observed the container (can) sanitizer rinsing process. You identified a significant amount of sanitizer rinse solution left inside the can. You ask to have a can pulled post rinse and were able to pour out sanitizer wash solution from the can. The facility, without documentation or regulation, verbally stated that 5g/2% of product weight of sanitizer per can was acceptable within the unit. 2. During the walkthrough, you observed excessive condensation on the ceiling and HVAC units throughout the facility directly above product and food-contact surfaces, including in the WIP cooler and over unprotected, cleaned, and sanitized food-contact bins in the washroom. Also, condensation was observed on the ceiling above the hopper for the machine where slurries for the whipped cream are manufactured. The QA manger response was the product receives a lethality in the final package and the product remains unexposed after the heat treatment, hence the food safety risk is low. 1 Major 1. HACCP Design/validation 1 Critical 2. Sanitation Controls | Global Food Safety

Case Study #7 (Answer) 1 Major : RMHA (Due to space constraints only few significant hazards are illustrated here) (1) Ingredient (2) (3) (4) (5) Identify potential food safety hazards introduced, controlled or enhanced at this step Is this a significant hazard? Justify your decision for column 3 What preventive control measure(s) can be applied to significantly minimize or prevent the food safety hazard? Process including CCPs, Allergen, Sanitation, Supply-chain, other preventive control Supply Chain-preventive control Yes X No Skim Milk Powder B Presence of VP - Salmonella spp., L. monocytogenes Allergen Milk None Presence of VP - Salmonella spp., Epidemiological evidence suggests that Chocolate type of products have been associated with pathogens such as Salmonella and L. monocytogenes in the absence of FS controls Milk is an allergen that must be labeled to inform consumers. C P B X Allergen Control allergen labeling Cocoa X Epidemiological evidence suggests that Chocolate type of products have been associated with pathogens such as Salmonella in the absence of FS controls Various studies over the last decade have shown the presence of mycotoxins like Aflatoxin and Ochratoxin in Cocoa related products. This may occur due to damaged cocoa pod kernels. Lead should also have been considered as a potential heavy metal. Supply Chain-preventive control C Mycotoxins- Aflatoxin, Ochratoxin X Supply Chain-preventive control P B None Presence of VP - Salmonella spp., Roasted Hazelnuts X Epidemiological evidence suggests that Chocolate type of products have been associated with pathogens such as Salmonella in the absence of FS controls Hazelnuts represent a potential source of mycotoxins that pose a public health issue due to their increasing consumption as food ingredients worldwide. Supply Chain-preventive control C Mycotoxins X Supply Chain-preventive control | Global Food Safety None P

Case Study #8 (Answer) 1. RMHA showed that potential pathogens of concern on avocadoes include Salmonella, E. coli and L. monocytogenes. HPP is used as a kill step and validation study documentation was provided for L. monocytogenes. The parameters were adequately documented in the CCP summary of the HACCP plan. CCP record review was also satisfactory. 2. Several dry ingredients such as Dehydrated Garlic, Dehydrated Onion, Garlic Puree, Jalapeno Pepper Powder were added to the guacamole formulation before the application of HPP. Supplier did not establish any supply chain controls to verify of the microbial hazards on these dry ingredients are effectively controlled. (Should be OK since the ingredients are added before the kill step (scope: microbial hazards only). This may be an issue based on the intended storage of the product and in-process controls) 1 Major: 1. RMHA | Global Food Safety