Eben Creaser - Chief Boiler Inspector & Chairman of PE Board

Eben Creaser, a seasoned professional with vast experience in boiler inspection, elevator inspection, and power engineering. He holds multiple endorsements and has been a key figure in ensuring safety compliance in various technical inspection services in New Brunswick. Learn about his contributions to the industry and the regulations governing boiler and pressure vessel operations.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

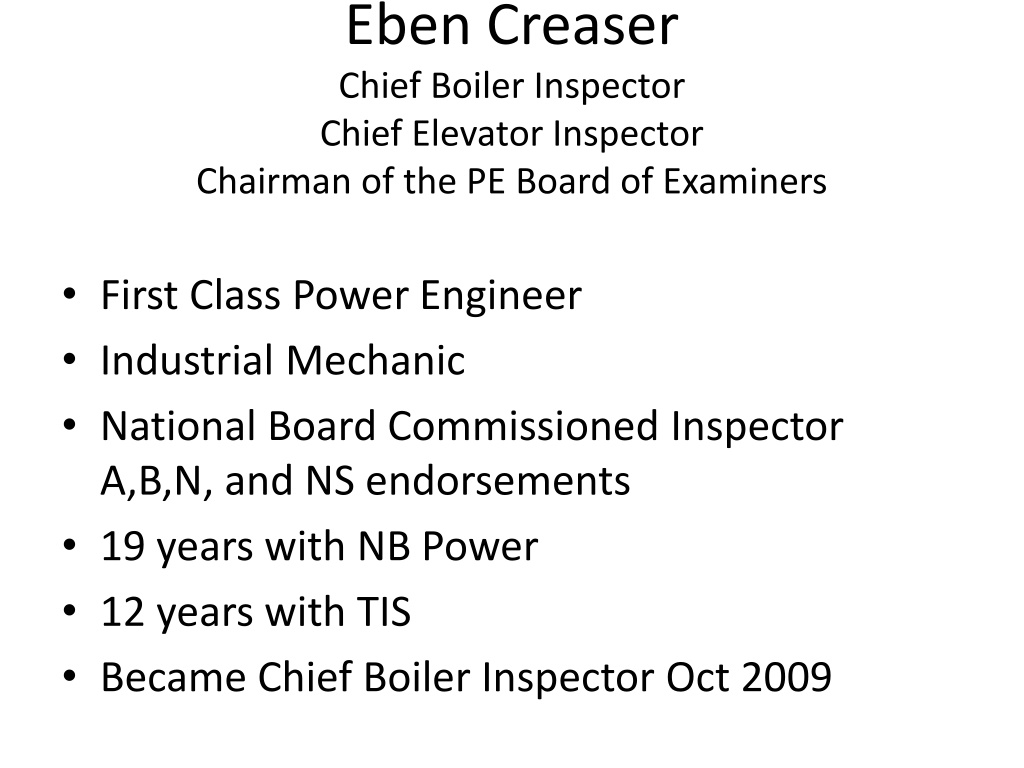

Eben Creaser Chief Boiler Inspector Chief Elevator Inspector Chairman of the PE Board of Examiners First Class Power Engineer Industrial Mechanic National Board Commissioned Inspector A,B,N, and NS endorsements 19 years with NB Power 12 years with TIS Became Chief Boiler Inspector Oct 2009

NB Public Safety Technical Inspection Services Electrical Elevators and Lifts Plumbing Fire Boiler and Pressure Vessels (Gas) Coming soon Building and Oil

TIS Boiler and Pressure Vessel Program Provides inspections on new boiler, pressure vessel, gas installations (large and small) Oversees and issues licenses for welders, power engineers, steam fitter/pipe fitter, gas technicians Provides shop inspection for boiler and pressure vessel and pressure piping manufacturing in New Brunswick for CSA B51 certified manufacturers As an ASME Authorized Inspection agency provides AI Inspection to ASME Manufacturers in NB and PEI Provides Nuclear Inspection services to NB Power as required by the CNSC Performs periodic inspections on existing boilers and pressure vessels based on risk based inspection frequency

New Brunswick Boiler and Pressure Vessel Act and Regulations 84-174,175,176,177. Road Map to Compliance

Boiler and Pressure Vessel Act C 122 (formally B7.1) The Act provides the frame work for Regulations The Act spells out the scope and what Regulations can be made under the Act The Act assigns responsibilities for administration the provisions of the Act and Regulations The Chief Inspector, Power Engineers Board of Examiners and the Compressed Gas Board of Examiners

The Regulations 84-174 Rules related to manufacturing/fabrication/design/Canadian Registration Numbers/quality assurance/certification/welding/welders/etc 84-175 Rules related to Boiler Installations/Power Engineer Staffing/Power Engineering Licensing/Power Engineering Duties and Responsabilities

The Regulations (cont) 84-176 Rules related to Compressed Gas/Natural Gas/LPG (propane)/Medical Gas/Diagester Gas/Landfill Gas/Permits/Licensing 84-177 The Standards Regulation which lists the Codes and Standards adopted and used for compliance with 84-174 thru 84-176

Regulation 84-174 Content PART I - GENERAL REQUIREMENTS PART II - DEFINITIONS PART III - REGISTRATION OF DESIGNS PART IV -REGISTRATION OF DESIGNS FOR FITTINGS PART V - RULES FOR WELDING PROCEDURES, WELDERS AND WELDING OPERATIONS PART VI-INSPECTORS AND INSPECTIONS PART VII FEES

84-174 over view The requirements of the Regulations trump the Codes and Standards The Regs is based on CSA B51 CSA B51 relies on ASME BPV Code for specific design rules for Boilers and Pressure Vessels CSA B51 adds some special enhancements (only in Canada) requirements Set out the basis for acceptance of pressure equipment based on the origin of manufacture

CRN = Canadian Registration Number The design of any Boiler, Pressure Vessel, or pressure piping system shall be registered Paragraph 301 : Before commencing construction of any boiler, pressure vessel or pressure piping system, the manufacturer shall submit the design for the boiler, pressure vessel or pressure piping system for registration

CRN (a)directly to the Chief Inspector, or (b)to the Chief Inspector through a design review organization approved by the Chief Inspector We always use option (b) ACI Central, www.acicrn.com All fittings used in the fabrication of a pressure piping system mus be registered

CRNs for Boilers and Pressure Vessels Detailed drawings and pressure retaining calculations in accordance with ASME BPV Code must be submitted by the manufacturer prior to the start of fabrication For the registration of standard fittings built to a standard ie ASME B16.5 (flanges) B 16.34 (valves) etc, proof of an acceptable quality system (certificate) and a Statutory Declaration is required for registration

Refrigeration Systems Typically made up of compressor(s), condensers, evaporators, receivers, and components connected with pressure piping systems By policy NB Regulation 84-174 is enforced when the refrigeration system contains a pressure vessel (usually the liquid receiver) that meets the definition of pressure vessel >1.5 cuft, + > 6 OD, + >15psi

September 27, 2005, To Whom It May Concern: In an effort to clarify when an installation permit is required for refrigeration systems, the Chief Boiler Inspector has provided the following ruling for all individuals and companies involved in the refrigeration installation and maintenance business. All individuals and companies installing, altering, or making additions to a refrigeration system(s) that contain a pressure vessel(s) must take out an installation permit. As described in the Boiler and Pressure Vessel Act B 7.1, a pressure vessel is an apparatus or device with a diameter greater than six inches, a capacity of more than one and one half cubic feet, and a pressure of greater than fifteen pounds per square inch. Pressure vessels are usually found in refrigeration systems as liquid receivers. All installations requiring permits will be inspected by a Boiler Inspector, and certificates of inspection will be issued. The individuals or companies performing the work must have a registered Quality Control Manual. All welding/brazing will be performed in accordance with registered welding/brazing procedures, and any person performing the welding/brazing will be tested and licensed by the Department of Public Safety.

Refrigeration cont Installation permits are required Licensed welders and braziers are required Installers must have a quality control system certificate Inspection and test plans (ITPs)must be developed and reviewed with the local boiler inspector prior to installation as per QA/QC system

Refrigeration cont Installation must be in compliance with CSA B52 Although not the responsibility of NB Public Safety, Refrigeration and Air Conditioning Mechanic is a compulsory trade under the Occupation and Certification Act which means any person carrying out the trade must hold a CofQ in the trade or be a registered apprentice. This is enforced by PETL

Refrigeration cont Most significant issues are related to; lack of CRNs on pressure vessels, unqualified personnel brazing or welding (unlicensed), non-compliance with CSA B52 requirements as it relates to machine room requirements, ventilation, doors, fire stopping, etc.

Gas Propane/Natural/Medical Governed by NB Regulation 84-176 This Regulation applies to (a)the manufacture, storage, transportation, handling, installing, testing and inspecting of gas and medical gas and of the associated appliances and equipment for the utilization of gas, (b)the maintenance of appliances and equipment for the utilization of gas, and (c)the installing, testing and inspecting of gas and medical gas piping systems.

Gas Inspection Program Falls under the Chief Boiler Inspector and the Boiler and Pressure Vessel Act Managed by Mike Davidson Inspections performed by four regional Inspectors, Moncton, Saint John, Fredericton, GrandFalls

Gas Continued The gas industry and gas technology in New Brunswick continues to transform We are seeing more and different gas installations being made Compressed Natural Gas, Digester Gas, Landfill, Enriched Hydrogen methane, syngas are all being actively worked on or in the planning stages

Gas cont In order to keep up with technology NB TIS is currently working on updating 84-176 to keep up with new and emerging gas technology

Gas Propane and Natural gas appliance installations shall comply with CSA B149 series of standards as applicable Gas installations generally consist of a piping system and an appliance The code break between the piping system and appliance is at the outlet of the appliance shut off valve

84-176 The regulation requires contractors to have: Gas Business Licence Licensed Gas Technicians Installation Permits Design Reviews for installations > 5 million BTUs or additions or Mods to installations > 5 million Btus

84-176 cont Appliances must be approved 7The Chief Inspector may accept as approved (a)gas and medical gas appliances and equipment tested and listed by: (i)the Canadian Standards Association; (ii)the Canadian Gas Association; (iii)the Underwriters Laboratories of Canada; (iv)Factory Mutual; or (v)a laboratory not listed in subparagraphs (i) to (iv) that is acceptable to the Chief Inspector; and (b)fittings tested and listed by the Underwriters Laboratories Incorporated or any other laboratory acceptable to the Chief Inspector.

Plan Approvals Recently changed from being performed by ACI Central and now being performed in house

Questions and answers ? ? ? ? ? ? ?