Importance of Fire Safety in Auto Repair Shops

Fire safety is crucial in auto repair shops due to the presence of flammable fluids and ignition sources. This presentation highlights the evaluation of fire hazards and strategies to mitigate risks. Damage caused by shop fires can be devastating, leading to injuries and equipment damage. Learn from a historic shop fire incident that occurred in November 2019.

Uploaded on Sep 15, 2024 | 0 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

FIRE SAFETY IN AUTO REPAIR SHOPS NOTHING ACTS FASTER THAN FIRE PREVENTION This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 1

INSTRUCTORS NOTES: FIRE SAFETY IN AUTO REPAIR SHOPS Fire safety is extremely important in an auto repair shop. Automobiles contain many flammable fluids such as gasoline, degreasers, solvents, and paint products. At the same time, car engines and shop electrical equipment are ignition sources capable of starting a fire. This presentation describes how to evaluate a shop for fire hazards and how to mitigate those hazards 2 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

FIRE SAFETY REDUCES RISK This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. endorsement by the U.S. Government. This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply

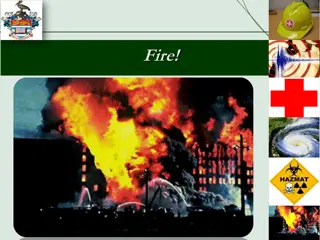

INSTRUCTORS NOTES: DEVASTATING SHOP FIRE A fire can prove to be very costly for a shop, both in terms of employee injuries and damaged equipment. This 100 year old historic shop was completely destroyed by a fire on 7 November 2019. Fortunately everyone in the shop was able to escape, but the owner suffered burns to his hands. The fire was ignited by a shop vacuum. 4 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

DEVASTATING SHOP FIRE November 2019, Lake Ronkonkoma, Long Island 5 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

INSTRUCTORS NOTES: FIRE PREVENTION PLAN The Occupational Safety and Health Administration (OSHA) 29 CFR requires employers of more than 10 people to establish a written fire prevention plan. Although not required for smaller auto repair shops, developing a fire prevention plan will enable managers to create a safer shop. 6 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

FIRE PREVENTION PLAN 7 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

INSTRUCTORS NOTES: ELEMENTS OF A FIRE PREVENTION PLAN The elements of a fire prevention plan are: 1. Have a written plan 2. Communicate the plan 3. Install fire warning and suppression equipment 4. Develop an emergency action plan 5. Evaluate the shop for fire hazards 6. Reduce or eliminate fire hazards 8 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

ELEMENTS OF A FIRE PREVENTION PLAN 1. Have a written plan 2. Communicate the plan 3. Install fire warning and suppression equipment 4. Develop an emergency action plan 5. Evaluate the shop for fire hazards 6. Reduce or eliminate fire hazards 9 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

INSTRUCTORS NOTES: FIRE TRIANGLE The triangle illustrates the three elements a fire needs to ignite: heat, fuel and oxygen. The heat comes from an ignition source such as an engine being serviced or a spark from electrical equipment. The fuel comes from flammable products in the shop, and the oxygen is present naturally in the atmosphere. Fire prevention in an auto repair shop can be challenging because of the abundance of fuel and ignition sources. 10 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

FIRE TRIANGLE Fuel Flammable liquids and gases Combustibles such as paper Used shop rags Car interiors Ignition sources Engines Electrical equipment 11 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

INSTRUCTORS NOTES: MAPPING FIRE HAZARDS Mapping the locations of fire hazards in your shop will assist with the development of mitigation strategies. Here is a map with potential fire hazards marked. The yellow triangles indicate flammables such as products containing volatile organic compounds or VOCs, waste motor oil, paper, and used shop rags. The plug symbols indicate electrical equipment. Cars are also an ignition source. 12 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

MAPPING FIRE HAZARDS 13 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

INSTRUCTORS NOTES: FIRE MITIGATION STRATEGIES 1-5 Mitigation strategies are actions or programs to reduce or eliminate the risk generated by a hazard. We are going to discuss nine fire mitigation strategies: 1. Eliminate ignition sources 2. Store flammable products safely 3. Maintain a clean shop 4. Prevent spills 5. Clean up spills promptly . 14 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

FIRE MITIGATION STRATEGIES 1-5 1. Eliminate ignition sources 2. Store flammable products safely 3. Maintain a clean shop 4. Prevent spills 5. Clean up spills promptly 15 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

INSTRUCTORS NOTES: FIRE MITIGATION STRATEGIES 6-9 6. Handle wastes properly 7. Use water-based cleaners or less toxic solvents for degreasing and cleaning 8. Use a parts washer with lids instead of open buckets or pans which often results in unnecessary spillage and evaporation 9. Store used rags safely 16 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

FIRE MITIGATION STRATEGIES 6-9 6. Handle wastes properly 7. Use water-based cleaners for degreasing and cleaning 8. Use parts washer with lids rather than open buckets or pans 9. Store used rags safely 17 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

INSTRUCTORS NOTES: POTENTIAL IGNITION SOURCES Malfunctioning electrical equipment. Damaged or poorly grounded electrical equipment. Flammable products improperly stored near service bays. Smoking and portable space heaters are ignition sources that should never be allowed in the shop. 18 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

POTENTIAL IGNITION SOURCES Damaged or poorly grounded electrical equipment Flammable products improperly stored near service bays Smoking in the shop Portable space heaters 19 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

INSTRUCTORS NOTES: ELIMINATE ELECTRICAL HAZARDS Electrical cords are intact and have grounding prongs. No wires are frayed, damaged or taped off. Electrical equipment is grounded Wiring is enclosed in electrical metallic tubing or rigid metal pipe Electrical receptacles have no open grounds or reverse polarity Circuits are labeled and the circuit box is closed Access to the circuit box is clear within 5-10 feet 20 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

ELIMINATE ELECTRICAL HAZARDS Electrical cords are intact and have grounding prongs Electrical equipment is grounded Wiring is enclosed in electrical metallic tubing or rigid metal pipe Electrical receptacles have no open grounds or reverse polarity 21 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

INSTRUCTORS NOTES: REDUCE USE OF VOCS Many products used in an auto repair shop contain VOCs They evaporate easily and can ignite in the presence of an ignition source from an engine or electrical spark. Gasoline, brake cleaners, electrical contact cleaners, and paint products all contain VOCs. Shops can improve fire safety and protect the environment by reducing their use of products containing VOCs. 22 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

REDUCE USE OF VOCS Many shop products contain VOCs Evaporate very easily Can catch on fire if exposed to an ignition source Gasoline, brake cleaners, electrical contact cleaners, and paint products all contain VOCs 23 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

INSTRUCTORS NOTES: STORE FLAMMABLE PRODUCTS SAFELY Flammable products should be stored in a flammable storage cabinet if a shop has over a certain quantity of flammable products. For example, no safety cabinet is required to store less than 25 gallons of Category 1 flammable liquids in approved containers. Store products in a metal cabinet or flammable storage cabinet Locate cabinets away from ignition sources Restrict foot traffic through storage areas Have adequate ventilation to prevent accumulation of vapors and carbon monoxide from exhaust 24 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

STORE FLAMMABLE PRODUCTS SAFELY Store products in a metal cabinet or flammable storage cabinet Locate cabinets away from ignition sources Restrict foot traffic through storage areas Have adequate ventilation to prevent accumulation of vapors and carbon monoxide from exhaust Photo by Justrite Company 25 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

INSTRUCTORS NOTES: STORE LARGE CONTAINERS SAFELY Flammable storage cabinets for large containers and drums are available. Raise drums off the floor to prevent corrosion from leaks or sweating concrete Store containers so that it is easy to inspect for corrosion and leaks. Each container must have a legible label with expiration dates, contents, and manufacturer warnings. Stack containers to minimize tipping, puncturing, or breaking Lids are tight-fitting and sealed, and bungs are closed 26 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

STORE LARGE CONTAINERS SAFELY Stack containers to minimize tipping, puncturing, or breaking Raise drums off the floor to prevent corrosion from leaks or sweating concrete Label each container clearly Lids are tight-fitting and sealed, and bungs are closed Photo by New Pig Company 27 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

INSTRUCTORS NOTES: GROUND WHEN POURING FLAMMABLE LIQUIDS Static electricity is generated by friction between different types of materials, such as when flammable liquids are poured from one container into another. Static discharge is a major cause of industrial fires and explosions. To prevent static discharge, the dispensing and receiving containers must be connected by bonding wire and grounded. Use bonding wire to connect the dispensing container and receiving container to an outside ground 28 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

GROUND WHEN POURING FLAMMABLE LIQUIDS Static electricity is generated by friction between different types of materials Static discharge is a major cause of industrial fires and explosions Use bonding wire to connect the dispensing container and receiving container to an outside ground Photo by Justrite Company 29 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

INSTRUCTORS NOTES: MAINTAIN A CLEAN SHOP Our 3rd fire mitigation strategy is to keep a clean shop. Messy shops often contain an excess of combustibles such as rags, and paper. This debris can block fire escape routes; increase the chance of spills, and make spill Photo - https://fuelandfriction.com/weekend-warrior/7-mistakes-to-avoid-when-doing-an-engine-rebuild cleanup more difficult. Photo - https://fuelandfriction.com/weekend-warrior/7-mistakes-to-avoid-when-doing-an-engine-rebuild Photo - https://fuelandfriction.com/weekend-warrior/7-mistakes-to-avoid-when-doing- an-engine-rebuild 30 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

MAINTAIN A CLEAN SHOP 31 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not

INSTRUCTORS NOTES: PREVENT SPILLS Our 4th fire mitigation strategy is to prevent spills. Cars contain many flammable fluids that need to be drained before servicing, creating a high potential for spills. Preventing spills will improve fire safety, and reduce the possibility that technicians will slip and fall on slippery fluids such as motor oil. 32 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

PREVENT SPILLS 33 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not

INSTRUCTORS NOTES: METHODS TO PREVENT SPILLS Here are some ways that an auto repair shop can prevent spills. Install splash guards and drip boards on tanks and faucets Use roll up oil caddies and/or drip pans under vehicles to collect oil Install spill basins and dikes in storage areas 34 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

METHODS TO PREVENT SPILLS Install splash guards and drip boards on tanks and faucets Use roll up oil caddies and/or drip pans under vehicles to collect oil Install spill basins and dikes in storage areas 35 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

INSTRUCTORS NOTES: ADDITIONAL METHODS TO PREVENT SPILLS Here are more ways a shop can prevent spills of flammable liquids. Store engines on shallow trays or in heavy duty totes Use pump & spigot for dispensing bulk product Store materials near point of use to avoid spills while transporting them 36 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

ADDITIONAL METHODS TO PREVENT SPILLS Store engines on shallow trays or in heavy duty totes Use pump & spigot for dispensing bulk product Store materials near point of use 37 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

INSTRUCTORS NOTES: CLEAN UP SPILLS PROMPTLY Our 5th mitigation strategy is to clean up spills promptly when they do occur, so that flammable liquids do not remain and cause a fire hazard. Spill control materials must be available on site. Spill kits are useful for cleaning up larger spills. They contain personal protective equipment as well as absorbent pads and pillows to contain the spill. 38 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

CLEAN UP SPILLS PROMPTLY Fuel and oil spill kit from Oil Eater Battery acid spill kit from Enpac 39 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

INSTRUCTORS NOTES: HANDLE WASTE AUTO FLUIDS SAFELY Auto repair shops generate a lot of waste fluids such as used motor oil and used antifreeze. The 6th mitigation strategy is to store and dispose of used oil and other automotive fluids properly. https://www.newpig.com/expertadvice/customer-question-how-to-store-drums-filled-with-used-oil/ https://www.newpig.com/expertadvice/customer-question-how-to-store-drums-filled-with-used-oil/ Photo por New Pig Company: https://www.newpig.com/expertadvice/customer-question-how-to-store-drums-filled- with-used-oil/ https://www.newpig.com/expertadvice/customer-question-how-to-store-drums-filled-with-used-oil/ 40 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

STORE AND HANDLE WASTES SAFELY 41 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

INSTRUCTORS NOTES: USE WATER- BASED DEGREASERS Our 7th mitigation strategy is to use water-based degreasers instead of traditional solvent degreasers. Water-based degreasers contain much lower VOC concentrations and consequently are much less flammable. Most are non-flammable. They are composed of cleaning agents including detergents, alkaline chemicals, microbes, or a combination of these. Water-based cleaners can be used in conventional parts washer equipment. 42 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

USE WATER-BASED DEGREASERS Contain much lower VOC concentrations Most are nonflammable Composed of cleaning agents including detergents, alkaline chemicals and/or microbes Can be used in conventional parts washer equipment. 43 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

INSTRUCTORS NOTES: USE A PARTS WASHER Our 8th mitigation strategy is to use parts washers instead of open pans or buckets. Effective parts washers are now available for many applications. They range in size from sink-top to parts washers large enough to fit an entire engine. Keep lids closed and spray nozzle turned off when not in use. If solvents are necessary, use less toxic blends such as mineral spirits or terpenes. 44 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

USE A PARTS WASHER 45 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

INSTRUCTORS NOTES: STORE USED SHOP RAGS SAFELY Our final mitigation strategy is to store shop rags safely. Oily rags are a fire hazard, because they can spontaneously catch on fire even without an ignition source. Place used shop rags in a special air tight container In many jurisdictions, cloth shop rags can be laundered and reused. 46 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

STORE USED SHOP RAGS SAFELY Oily rags can spontaneously combust even without an ignition source Place used shop rags in a special air tight container 47 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

INSTRUCTORS NOTES: REVIEW Implementing these mitigation strategies will improve fire safety in your shop. Your reward for creating a fire prevention plan will be a safer and more efficient shop. 48 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

SAFER AND MORE EFFICIENT SHOP 49 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not