Guidelines for Pre-Inspection Briefing in Chemical Weapons Convention

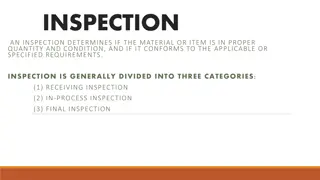

The Pre-Inspection Briefing (PIB) is a crucial initial activity in Chemical Weapons Convention (CWC) inspections, aimed at creating a cooperative atmosphere. This guideline outlines essential requirements for the PIB, including operational activities, safety measures, logistics, confidentiality, and more. It serves to assist industrial facilities subject to Article VI inspections in providing thorough and relevant information to inspection teams for efficient inspection planning and execution.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Pre-Inspection Briefing Guidelines SCHED2 Regime 1

Initial Disclosure The Pre-Inspection Briefing (PIB) is the first official activity at the inspected plant site, in a Chemical Weapons Convention (CWC) inspection. Therefore, it is critical that a cooperative atmosphere is created. This PIB guideline is intended for use by industrial facilities subject to Article VI inspections under the CWC. It serves the Inspected State Party to prepare a thorough, relevant and accurate technical briefing about the facility. That information provided is instrumental to develop inspection plans, helping the Inspection Team fulfil the aims of the inspection mandate in an efficient and timely manner. The guideline lays out basic requirements in PIB, including operational activities, safety measures, logistics, confidentiality, administration, and other site-specific information, among others. 22

General requirement This guideline is recommended to the Inspected State Party as reference only The PIB should be provided by facility representatives and conducted no more than 3 hours in length (as per CWC, VA, Part II, paragraph 37) The PIB presentation can be provided in various forms (e.g., PPT, projection, hardcopy). Hand-outs of the material presented during the PIB are recommended to be provided to the Inspection Team prior to the PIB. Any site and/or process diagrams could be handed as a separate print-out document from the PIB. This would provide the plant site and the host team better control over such documents during inspection activities. The Inspection Team will return all the PIB material at the end of the inspection 33

A. Introductions of participants Host team Names and functions Plant/Plant site personnel Participants names and functions 44

B. General Information Brief history of the company and basic information Type of industry (e.g., fertilizers, pharmaceuticals, pesticides, plasticizers, paints, soaps, etc.) Management, organization, operations, environment Certificates of accreditations (e.g., ISO, FDA, etc.) Security features (e.g., fence/wall, CCTV, patrols, others) 55

B. General Information Any changes in the facility (operational, organizational) since the last inspection (if applicable if applicable) Number of employees Aerial view map indicating: Location in relation to Point of entry (POE) Distance from POE Facility layout indicating: Boundaries and gates Total area of the plant site 66

C. Plant Site Safety Measures Related to inspection conduct: No operation/touching of equipment Need for escort Related to facility: Safety hazards and safety procedures Specific personal protective equipment Emergency alarms and response procedures Evacuation routes Assembly points Location of medical facilities 77

D. Logistics & Administrative Information Working hours: administration and operations Working spaces Inspectors and escort team working spaces (offices), and briefing areas Set-up inspection team office (lockable, power supplied, available during the entire inspection, equipped with desks and chairs) Communications/Mobile phone policy Transportation Lodging and meals Security and badging procedures 88

E. Physical Layout Provide Plant Layout or comprehensive list indicating the following: Declared Schedule 2 plant(s) Schedule 3 and DOC/PSF plant(s) (if any Common infrastructure (e.g., QC/R&D laboratories, waste treatment, maintenance, warehouses, pilot plants, medical facilities, etc.) Non-declarable plants (e.g., formulation, polymers, inorganic chemicals, etc.) Other companies / plant sites which may be physically located within the same boundary, but may not (operationally) form part of the inspected facility GPS reading point (if coordinates declared) (if coordinates declared) if any) 99

F. Detailed info Quantitative Information Declaration figures (indicate any changes /discrepancies in relation to the declared data) Identification of Schedule 2 plant(s) (e.g., building/structure, location, etc.) Main activities of Schedule 2 plants [ [expressed in terms of PGC, Click HERE] ] Activities in relation to Schedule 2 chemicals [Production (PROD) Processing (PROC), (PROC), Consumption (CONS) Characteristics of the plant(s) [Dedicated, Multipurpose] [Dedicated, Multipurpose] Other activities [ [expressed in terms of codes B04, B05, B06] Production capacity & method of calculation, if applicable Specific information in each Schedule 2 chemical [IUPAC/Trade names] names] (PROD) (CONS)] B04, B05, B06] [IUPAC/Trade 10 10

G. Overview of declared S2 activities Consider inclusion of the following for each Schedule 2 plant: Chemical PROD, PROC, CONS quantities (e.g., annual summary) Types of chemical reaction(s) with reaction schemes/process diagrams, (including downstream processes, e.g., filtration, distillation, centrifugation, etc.) Materials of construction (e.g., SS, CS, Hastelloy, etc.) Mode of operation: Batch/continuous Dedicated/multipurpose Type of control (e.g., manual, automatic, etc.) Associated infrastructure (e.g., tank farms, laboratories, etc.) Specific safety features (e.g., detectors, PPE) List all Scheduled chemicals on the plant site, even if under threshold levels 11 11

H. Records to be reviewed The records review process is not part of the PIB and therefore these documents should not be included in the PIB material. It s highly recommended to have these documents ready at the beginning of the inspection, to optimize the inspection process. The following is a non-exhaustive list of relevant records generally requested and accessed by the Inspection Team during the records review process 12 12

List of relevant records Record name Record name Purpose Purpose Certifications (e.g., ISO)& Business Registration documentation Annual/monthly summaries in relation to (PROD,PROC,CONS, Import, Export) Batch records/Daily inventory data/On-screen data Complete list of chemicals handled on site Waste analysis/emission analysis Verify name, owner, and address of the plant site Verify the level of declared activities, non-diversion Cross checking to confirm the integrity of the recording system Absence of Schedule1 and undeclared Schedule chemicals and activities Non-diversion and absence of any Schedule chemicals Purity of S2 chemicals COA of Sched 2 13 13

List of relevant records Record name Record name Purpose Purpose Technical data (SDS, basic chemistry) Identify chemical structure, composition of a mixture Explanation for discrepancy, if any Identification of causes (Calibration related, S2 chemical destruction) Methodology for recording systems Confirm the process of data capturing and register 14 14

I. Mass Balance -Example It is recommended that the ISP perform MB calculation in advance. It helps identify potential issues and prepare the rationales (Click HERE for instruction) Year -3 Year -2 Year -1 Up to date Decl. Verif. Decl. Verif. Decl. Verif. Decl. Verif. Opening stock Purchase (domestic) Import Production Consumption Processing Quantity 30% Transfers (domestic) Export Closing stock Physical Inventory on the DD MMM n.a. n.a. n.a. n.a. n.a. n.a. n.a. n.a. n.a. n.a. n.a. n.a. n.a. n.a. n.a. n.a. n.a. 0.00 n.a. 0.00 n.a. 0.00 n.a. 0.00 Discrepency rate #DIV/0! 15 15

J. List of acronyms Acronym Acronym Definition Definition CWC Chemical Weapon Convention DOC Discrete Organic Chemicals ISP Inspected State Party PIB Pre-Inspection Briefing PPE Personal Protection Equipment PSF An unscheduled discrete organic chemical containing the elements phosphorus sulfur or fluorine VA Verification Annex POE Point of Entry CS Carbon Steel SS Stainless Steel OCPF Other Chemicals Production Facility SDS Safety Data Sheet PGC Product Group Code 16 16

References Please refer to the links below for further examples and guidance on how to prepare a PIB USA National Authority https://www.cwc.gov/inspections_briefing_overview_text.html#topicFour UK National Authority https://assets.publishing.service.gov.uk/government/uploads/system/uploads/a ttachment_data/file/558885/OPCW_Inspection_Guidance__2016_.pdf 17 17