Comprehensive Guide to Highway Soil Compaction Methods and Equipment

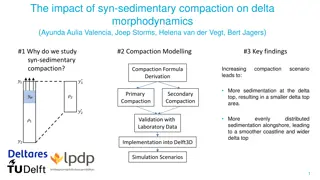

Understand the importance of compaction in highway soil types, whether cohesive or granular. Learn about suitable compaction equipment like rammers and vibratory plates, tailored for specific soil conditions. Watch online demonstrations for practical insights on achieving optimal compaction levels for different soil types.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Structural Design of Highway Soil Types and Conditions and Compaction Methods Highway and Transportation Engineering Al-Mustansiriyah University 2019-2020 Dr. Abeer K. Jameel & Dr. Rana Amir Yousif

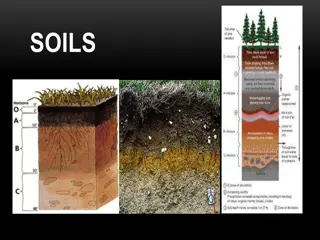

COMPACTION EQUIPMENT The desired level of compaction is best achieved by matching the soil type with its proper compaction method. Other factors must be considered as well, such as compaction specs and job site conditions.

COMPACTION EQUIPMENT Cohesive soils clay is cohesive; its particles stick together. Therefore, a machine with a high impact force is required to ram the soil and force the air out, arranging the particles. A rammer is the best choice or a pad-foot vibratory roller if higher production is needed.

COHESIVE SOILS MTX70 Rammer https://www.youtube.com/watch?v=_mrhgup8NH8

COHESIVE SOILS P33/24 HHMR ROLLER https://www.youtube.com/watch?v=pGIQLQOdRbI

COHESIVE SOILS RX15010CI ROLLER https://www.youtube.com/watch?v=P7PrTWBV_No

COMPACTION EQUIPMENT Granular soils since granular soils are not cohesive and the particles require a shaking or vibratory action to move them; vibratory plates (forward travel) are the best choice.

GRANULAR SOILS MVC-88 Vibratory Plate https://www.youtube.com/watch?v=Bo4Sp2-kmhc

GRANULAR SOILS MVH-306 Reversible Plate https://www.youtube.com/watch?v=FIAWk4ds9fI

GRANULAR SOILS AR-13H Ride-on Vibratory Roller https://www.youtube.com/watch?v=sLq1wkHYveU

Field Compaction Equipment Rollers are used for field compaction and apply either a vibrating force or an impact force on the soil. The type of roller used for any particular job depends on the type of soil to be compacted. A smooth wheel or drum roller applies contact pressure of up to 55 lb/in2 over 100 percent of the soil area in contact with the wheel. This type of roller is generally used for finish rolling of sub-grade material and can be used for all types of soil material except rocky soils. https://www.youtube.com/watch?v=_TpTgrtH8H8 Smooth Wheel or Drum Roller

Field Compaction Equipment The rubber-tired roller is another type of contact roller, consisting of a heavily loaded wagon with rows of 3 to 6 tires placed close to each other. The pressure in the tires may be up to 100 lb/in2. They are used for both granular and cohesive materials. Rubber-Tired Roller https://www.youtube.com/watch?v=nOvpoZhz2l0

Field Compaction Equipment Tamping foot rollers They are used to obtain high contact pressures, ranging from 200 to 1200 lb/in2. The feet of the tamping foot rollers are specially hinged to obtain a kneading action while compacting the soil. tamping foot rollers compact from the bottom of the soil layer. https://www.youtube.com/watch?v=Q7Ck7BMtSPs www.youtube.com/watch?v=UR2B6f28-4E Tamping Foot Rollers

Structural Design of Highway Dr. Rana Amir Yousif & Dr. Abeer K. Jameel