Vintech Polymers Reputed Supplier of Industry-Standard In-Mold Labels with Strong Adhesive

In-mould labelling is a process in which the in-mould film is placed inside the mould during the manufacturing of containers by blow molding, injection molding, or thermoforming processes. This is done at high pressure where the pre-heated plastic is

Uploaded on | 0 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

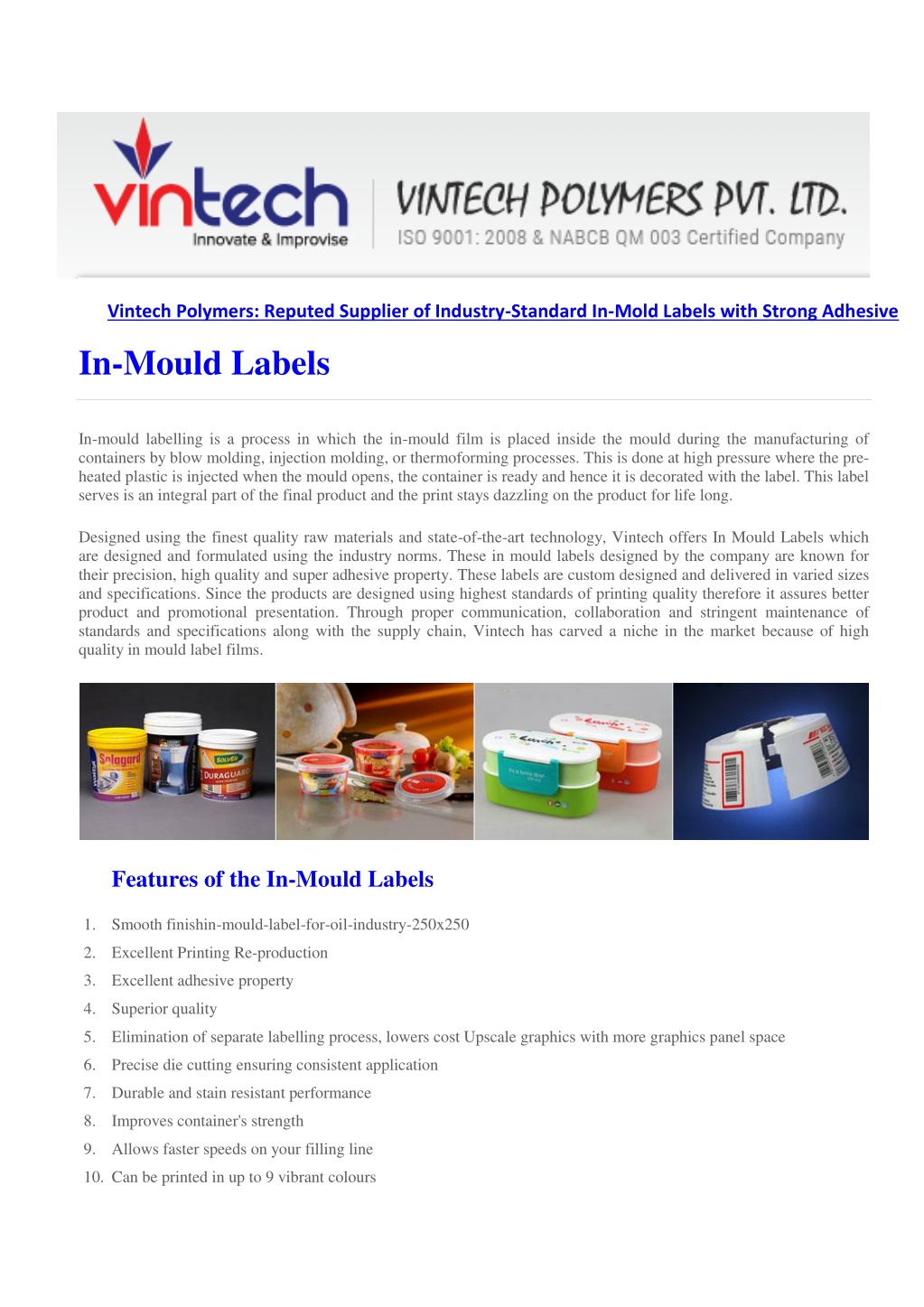

Vintech Polymers: Reputed Supplier of Industry-Standard In-Mold Labels with Strong Adhesive In-Mould Labels In-mould labelling is a process in which the in-mould film is placed inside the mould during the manufacturing of containers by blow molding, injection molding, or thermoforming processes. This is done at high pressure where the pre- heated plastic is injected when the mould opens, the container is ready and hence it is decorated with the label. This label serves is an integral part of the final product and the print stays dazzling on the product for life long. Designed using the finest quality raw materials and state-of-the-art technology, Vintech offers In Mould Labels which are designed and formulated using the industry norms. These in mould labels designed by the company are known for their precision, high quality and super adhesive property. These labels are custom designed and delivered in varied sizes and specifications. Since the products are designed using highest standards of printing quality therefore it assures better product and promotional presentation. Through proper communication, collaboration and stringent maintenance of standards and specifications along with the supply chain, Vintech has carved a niche in the market because of high quality in mould label films. Features of the In-Mould Labels 1.Smooth finishin-mould-label-for-oil-industry-250x250 2.Excellent Printing Re-production 3.Excellent adhesive property 4.Superior quality 5.Elimination of separate labelling process, lowers cost Upscale graphics with more graphics panel space 6.Precise die cutting ensuring consistent application 7.Durable and stain resistant performance 8.Improves container's strength 9.Allows faster speeds on your filling line 10.Can be printed in up to 9 vibrant colours

The benefits of In mould Labeling 1.The biggest advantage of using in mould labelling is the freedom from glue residues, wrinkles, blisters. The label is strtched on the container in a perfect manner. 2.It is one of the quickest and cost effective method to change the design of the label. 3.This process is environment friendly and easily recyclable because the container and the labels are made from one and same material. 4.In-mould labelling delivers manufacturing economies and efficiencies without sacrificing the aesthetics of the product packaging." 5.The labels are made from PP film which is an excellent medium for high resolution and photo-realistic image reproduction. 6.Its a single step process for both the molding and labelling of the product. This ensures the security of the pack because it is not possible to remove or replace the label which is permanently bonded to the pack. 7.These in mould labels are quite hygenic to be used for the food products, since they are environmentally friendly and easily recyclable. 8.It helps to give quite a different and distinct identity to your product and set it apart from rest of the product in the market during sale. 9.Since they are moisture and temperature resistant, hygenic etc it makes them an excellent solution for plastic packaging for frozen or refrigerated products. Applications of In Mould Labels 1.Food and beverages

2.Paint pail industry 3.Oil, grease and lubricant pail industry 4.Agriculture and seeds pail industry 5.Household items If you are looking out for quality product packging, opt for in mould labelling from Vintech which integrates a downstream process with the injection molding process. In today s fast-paced manufacturing world, in-mold labels (IML) have become a popular solution for product labeling. Whether in the packaging industry or for consumer goods, this innovative labeling technique offers significant advantages over traditional methods. As a leading in-mold labels manufacturer in India, Vintech Polymers provides high-quality, durable, and visually appealing labels with strong adhesives that meet the diverse needs of industries worldwide. What is In-Mold Labeling? In-mold labeling (IML) is a process where labels are applied during the molding process, becoming an integral part of the final product. The result is a seamless, high-quality finish where the label looks as if it is part of the product rather than an additional layer. In-mold labeling injection molding is the most commonly used process, especially in industries that require durable and long-lasting labeling solutions. Benefits of In-Mold Labeling: Durability: Since the label is fused with the product during molding, it is resistant to wear, tear, and environmental factors like moisture and UV exposure. Enhanced Appearance: The in-mould label printing process ensures that labels are vibrant, high-definition, and long-lasting. Efficiency: By integrating labeling into the molding process, businesses save time and reduce the need for additional post-production labeling. In-Mold Labeling Process: How It Works The in-mold labeling process involves placing a pre-printed label inside the mold before the product is injected with plastic or another material. As the material fills the mold, it bonds with the label, creating a single, seamless product. Key Steps in the In-Mold Labeling Process: 1.Pre-Printed Labels: High-quality, pre-printed labels are created using the in-mould label printing process. These labels are typically made from materials such as polypropylene (PP) or polyethylene (PE), ensuring durability and compatibility with the molding material. 2.Label Placement: The label is placed inside the mold cavity, either by a robotic arm or manually, ensuring precise positioning for optimal results.

3.Injection Molding: During the in mold labeling injection molding phase, plastic is injected into the mold. The heat and pressure from the molding process cause the label to fuse with the material, creating a single, cohesive unit. 4.Final Product: The finished product emerges from the mold with the label seamlessly integrated into its surface, offering a high-quality, durable, and aesthetically pleasing result. Why Choose In-Mold Labeling? Industries looking for premium branding options turn to IML in mold labeling because it offers a superior solution in terms of durability, cost-effectiveness, and design flexibility. It is particularly useful for products that will face heavy wear or exposure to harsh environments. Advantages of IML in Mold Labeling: Cost-Effective: The in-mould labeling process eliminates the need for secondary labeling, reducing production time and labor costs. Environmental Benefits: Labels used in in mould labelling are typically recyclable, aligning with eco-friendly initiatives. Branding Flexibility: IML in mold labeling allows for complex designs, high-resolution images, and unique textures to be integrated seamlessly into the product, providing brands with endless customization options. In-Mould Labeling Companies in India In India, in-mould labeling companies are emerging as leaders in the global market. Vintech Polymers is at the forefront of this industry, supplying high-quality, durable in-mould labels to a wide range of sectors, including food packaging, household products, and industrial goods. Why Vintech Polymers is a Leading In-Mould Labeling Company: Industry Expertise: With years of experience in in-mold labels manufacturing, Vintech Polymers has become a trusted partner for businesses across various industries. Cutting-Edge Technology: Their advanced printing and manufacturing techniques ensure that every label meets strict quality standards. Customization: Vintech Polymers offers tailored solutions to meet the unique needs of each client, providing labels that enhance the product s functionality and aesthetic appeal. Vintech Polymers: Leading In-Mold Labels Manufacturer in India As a prominent in mould labels manufacturer in India, Vintech Polymers has built a reputation for supplying high-quality, durable labels that meet international standards. Their labels are known for their strong adhesive properties, ensuring they bond seamlessly with the product during the molding process. Why Choose Vintech Polymers: High-Quality Materials: Their labels are made from top-grade materials, ensuring they are durable, resistant to environmental factors, and perfect for a wide range of products.

Strong Adhesive: Vintech Polymers in-mould labels feature a robust adhesive that guarantees a permanent bond with the molded product, enhancing the overall durability. Custom Solutions: They offer fully customizable in mould printing solutions, ensuring that each label is perfectly suited to the client s branding and functional requirements. In-Mould Labels Supplier in India As a trusted in-mould labels supplier in India, Vintech Polymers supplies labels for various applications, including food packaging, automotive parts, and household goods. Their extensive product range ensures that businesses can find the perfect labeling solution for their needs. Vintech Polymers Offers: Food-Grade Labels: Suitable for food containers and packaging, their labels meet safety standards while offering vibrant, long-lasting designs. Durable Industrial Labels: For products that require extra durability, such as automotive or industrial components, Vintech Polymers offers labels that can withstand harsh conditions. Household Product Labels: Their labels for household products are designed to resist moisture, cleaning chemicals, and other environmental factors, ensuring they remain intact throughout the product s lifespan. In-Mould Labels Supplier in India for Various Industries Vintech Polymers is not just an in-mould labels manufacturer; they are also a versatile supplier, catering to a wide range of industries. Whether you need labels for consumer goods, packaging, or industrial products, their labels offer the perfect blend of durability, aesthetic appeal, and functionality. Industries Served by Vintech Polymers: Packaging: Their in-mould labels are ideal for rigid packaging applications, including food containers, cosmetic jars, and more. Automotive: Vintech Polymers provides durable labels for automotive components, offering resistance to heat, chemicals, and mechanical wear. Consumer Goods: Their labels for consumer goods ensure that products not only stand out on the shelves but also maintain their appearance and functionality throughout their usage. Conclusion: Vintech Polymers: Your Trusted Partner for In-Mold Labeling Solutions For businesses seeking the best in in-mould labeling, Vintech Polymers is the ideal partner. As a leading in mould labels manufacturer in India, they offer high-quality, durable, and customizable labeling solutions that cater to a wide range of industries. Their strong adhesive labels, expert manufacturing processes, and commitment to quality make them the go-to in mould labels supplier in India for businesses looking to enhance their product branding and functionality. Whether you need labels for packaging, automotive parts, or consumer goods, Vintech Polymers delivers industry-standard solutions that meet your exact specifications. Choose Vintech Polymers for the highest quality in-mould labeling solutions in India.

Get in touch with us: Vintech Polymers Private Limited B.W. Industrial Complex 179/7 & 9, Badu Road, Digberia Madhyamgram, 24 Pgns (N) Kolkata - 700 128 (W.B.) India +91 33 2526 0204 +91 9831016222, +91 9831070140 vintechpoly@gmail.com OVERSEAS MARKETING OFFICES Dubai: +971 555440399 Colombo: +94 772977167 Visit http://www.vintechpoly.com Steel Heat Transfer labels manufacturer in India, Shrink Sleeves for Cap Sealing manufacturer in India, In-Mould Labels manufacturer in India, Shrink Sleeves for Container Sealing manufacturer in India, Heat Transfer Labels manufacturer in India, BOPP Wrap Around Labels manufacturer in India, Shrink Sleeves for General Packaging manufacturer in India, Shrink Labels for Dry Cell Batteries manufacturer in India, PVC Shrink Labels manufacturer in India, PET Shrink Labels manufacturer in India, PVC Lamination Films manufacturer in India, Shrink Sleeves for Promotional Pack manufacturer in India, PVC films manufacturer in India, ABS container Heat Transfer labels manufacturer in India, Container Heat Transfer labels manufacturer in India, Stationery Heat Transfer labels manufacturer in India, Paper Heat Transfer labels manufacturer in India, Thermoforming IML manufacturer in India, Shrink Sleeves for Cap Sealing manufacturer, In-Mould Labels manufacturer, Shrink Sleeves for Container Sealing manufacturer, Heat Transfer Labels manufacturer, BOPP Wrap Around Labels manufacturer, Shrink Sleeves for General Packaging manufacturer, Shrink Labels for Dry Cell Batteries manufacturer, PVC Shrink Labels manufacturer, PET Shrink Labels manufacturer, PVC Lamination Films manufacturer, Shrink Sleeves for Promotional Pack manufacturer, PVC films manufacturer, Comb Heat Transfer labels manufacturer, Stationery Heat Transfer labels manufacturer, ABS container Heat Transfer labels manufacturer, PP container Heat Transfer labels manufacturer, Steel Heat Transfer labels manufacturer, Container Heat Transfer labels manufacturer, Paper Heat Transfer labels manufacturer, Photo frame Heat Transfer labels manufacturer