Enhancing Pavement Performance with Tiered Superpave Specifications

Explore innovative strategies in rethinking polymer-modified asphalt timing to reduce age-induced surface damage. Discover tiered cracking specifications, PG grade bumping for quality standards, and the evolving PG specifications for cracking resistance. Delve into research needs for optimizing pavement performance timing, the impact of early seals on aging rates, and the use of recycling/rejuvenators in high RAP/RAS mixtures.

- Pavement Performance

- Superpave Specifications

- Age-Induced Damage

- Polymer-Modified Asphalt

- Crack Prevention

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Rethinking PP Timing Strategies Tiered Superpave Specifications to Reduce Age-Induced Surface Damage Emulsion Task Force Indianapolis June 13, 2019 Gayle King

Outline Tiered Cracking Specifications Background PP Roadmap PG & Superpave Implementation Increasing demand for high RAP mixes (9-58) Evolving PG specifications for cracking (9-59;-60) G* max; Minimum Tc (or equivalent); G-R Impact on asphalt supply and use of RAP Questions: Can seals limit age-induced surface damage? Should seals be part of a tiered approach that pavement designers use to limit surface damage?

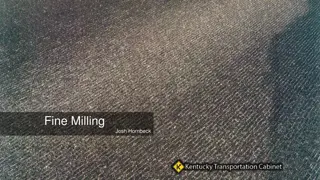

PP Roadmap Research Needs: Materials Materials Research Need Statement Optimize PP timing strategies based upon in-place material properties Estimated cost: $10 million Can early seals reduce aging rates near the pavement surface? Probably yes! Pooled Fund Study: AI: M. Anderson, Blankenship, King Supported by: MN, MD, OH, WI, TX, FHWA, MLRRB CTAA 2016: Early seals slow evolution of aging: G-R, LAS AAPT 2016: DC(T) testing, including early seal effectiveness Agencies now chip seal new rural AC pavements. SD,MN

PG Grade Bumping Tiered Quality Standards for Rutting Premise: Mixes require stiffer binders at high summertime temperatures when subjected to heavy, slow moving traffic. Tiers: G*/sin MSCR Standard: M320 @ Th; M332: Jnr 4.0 Heavy: M320 @ Th+6C; M332: Jnr 2.0 Very Heavy: M320 @ Th+12C; M332: Jnr 1.0 Extreme: M320 @ Th+18C; M332: Jnr 0.5 To Meet Spec: add more polymer/additive

Recycling/Rejuvenators High RAP/RAS Problem: RAP mixtures prone to early surface damage. NCHRP 9-58 TX A&M High RAP/RAS study for TXDOT Softer virgin AC with PAV20 Tc of -4.5 RAP had much lower Tc Sections with various recycling agents Surface damage: < 1 year Loving County, TX 20% RAP; Tc < -10 after construction Remove and replace in 4 months

Evolving PG Specifications for Cracking Failure Parameters and Early Implementation New surface damage failure parameters Black Space parameters: Tc, G-R, R-value Failure stress and strain: ABCD, Dent, S-Dent Fatigue: LAS Physical Hardening: Hesp approach, Tc Agencies implement stopgap specs (REOB) BBR: max G* and min Tc UT, FL, NV, Northeast DENT, Isothermal Hardening Ontario

Evolving PG Specifications for Cracking Impact on asphalt supply and use of RAP Black Space parameters ( Tc, R-value) are inherent crude quality parameters related to molecular motion at low pavement temperatures. Poor AC quality (low Tc) is difficult to restore, even with the best rejuvenators. Aging, REOB & wax negatively impact Tc. RAP quality matters! Polymers and other anti-rutting additives may reduce Tc, but rarely increase it.

A tiered quality specification for cracking Making Preservation Part of the Solution Where to set threshold values for Tc? Strict limits eliminate some asphalt sources and greatly restrict RAP use Less stringent limits shorten pavement surface life. Solution: Tiered quality standards for Tc Impose strict limits for high volume surface mixes Adopt intermediate limits for binder/base course and low volume surfaces Pavement Preservation option: Accept a third lower PG quality standard for base mixes, or for rural surface mixes (mill & fill) only if an air- impermeable seal is placed on the surface

Tiered Cracking Specifications What s missing? Research Needs: Establish appropriate Tc threshold values for traffic, climate, and pavement layer Modify LTPPBind grade selection Field research and models which tie effectiveness of early pavement seals to limit aging and/or moisture related damage Implementation/supply issues: Ease grade proliferation by tying tiered rutting grades to tiered cracking specs??

Tiered Cracking Specifications Where to start? Organize invited workshop, to include: Researchers for cracking specifications FAA & AASHTO Pooled-Fund Studies: AI NCHRP 9-58: TTI, UNH, UNR NCHRP 9-59: AAT, NCAT NCHRP 9-60: WRI, AAT, NCAT TRB/NCHRP: Ed Harrigan Stakeholder representation ETF Binder & Mix ETGs ?? Agencies/Universities implementing Tc: UT, FL, NV