Infusion Pump Design Considerations and Applications

Infusion pumps require careful consideration of design elements like air-in-line detection, pressure/occlusion sensors, and motor control. Different sensors and amplifiers are used to ensure patient safety and accurate medication delivery. TI offers a range of solutions to address the challenges faced in designing infusion pump systems, including sensor front-end designs and current sensing techniques.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

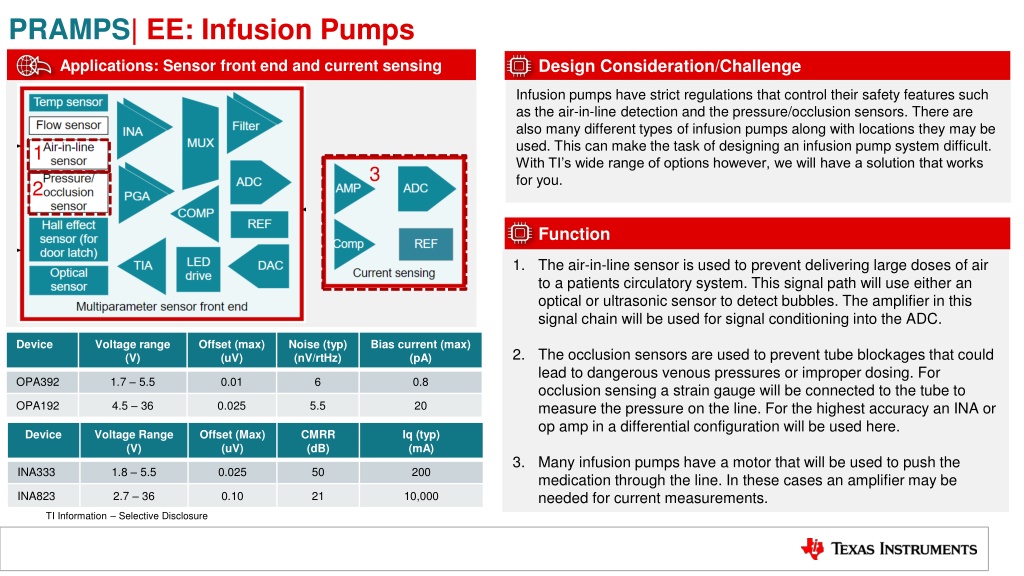

PRAMPS| EE: Infusion Pumps Design Consideration/Challenge Applications: Sensor front end and current sensing Infusion pumps have strict regulations that control their safety features such as the air-in-line detection and the pressure/occlusion sensors. There are also many different types of infusion pumps along with locations they may be used. This can make the task of designing an infusion pump system difficult. With TI s wide range of options however, we will have a solution that works for you. 1 3 2 Function 1. The air-in-line sensor is used to prevent delivering large doses of air to a patients circulatory system. This signal path will use either an optical or ultrasonic sensor to detect bubbles. The amplifier in this signal chain will be used for signal conditioning into the ADC. Device Voltage range (V) Offset (max) (uV) Noise (typ) (nV/rtHz) Bias current (max) (pA) 2. The occlusion sensors are used to prevent tube blockages that could lead to dangerous venous pressures or improper dosing. For occlusion sensing a strain gauge will be connected to the tube to measure the pressure on the line. For the highest accuracy an INA or op amp in a differential configuration will be used here. OPA392 1.7 5.5 0.01 6 0.8 OPA192 4.5 36 0.025 5.5 20 Device Voltage Range (V) Offset (Max) (uV) CMRR (dB) Iq (typ) (mA) 3. Many infusion pumps have a motor that will be used to push the medication through the line. In these cases an amplifier may be needed for current measurements. INA333 1.8 5.5 0.025 50 200 INA823 2.7 36 0.10 21 10,000 TI Information Selective Disclosure

PRAMPS| EE: Infusion Pumps 1: Air-in-line sensor Design Consideration/Challenge Applications: Gain Buffer To build a system that accurately and reliably detect micro air bubbles while minimize nuisance alarms due to smaller bubbles. The signal from the sensor will need significant gain before going to the ADC. Key Features & Product Highlights Due to the high gain requirements in signal chain amplifiers with low offsets and noise are recommended to reduce error. High Voltage Low voltage Low voltage Specifications OPA392 OPA2376 OPA192 1.7 5.5 2.2 5.5 4.5 36 Supply Voltage (V) Vos max (mV) (max) 0.01 0.025 0.025 Useful reference designs and collateral Drift typ (uV/C) (typ) 0.1 0.32 0.1 Offset Correction Methods: Laser Trim, e-Trim , and Chopper GBW (MHz) 13 5.5 10 Circuit Cookbook Slew Rate (V/ s) 4.8 2 20 The Signal e-book: A compendium of blog posts on op amp design topics Voltage noise (nV/rthz) 6 7.5 5.5 Bias Current (pA) (typ) 0.8 10 20 Output Current (mA) 65 30 65 TI Information Selective Disclosure

PRAMPS| EE: Infusion Pumps 2. Pressure/Occlusion sensor Design Consideration/Challenge Applications: input buffering & fault protection Low bridge sensitivity requires high gains & low input referred noise for the amplification stage. High input impedances are desirable to reduce interference with bridge. High CMRR is needed to minimize the effect of common mode input noise. Key Features & Product Highlights Solution: The INA line of instrumentation amplifiers offer low input offsets, single resistor selectable gains ranging from 1 to 10000, very high input impedance, and very high CMRR. Super-beta Low noise Wide supply Low cost Low voltage Zero-drift Specifications INA333 INA823* INA818 1.8 5.5 2.7 36 4.5 36 Supply Voltage (V) Useful reference designs and collateral Vos max (mV) 0.025 0.100 0.035 The Difference Between an Instrumentation Amplifier and a Current Sense Amplifier CMRR (min, G=1000) (dB) 100 120 140 Voltage noise (nV/rthz) 50 21 8 What is an instrumentation amplifier? Bias Current (typ) (nA) 0.07 10 0.150 Quiescent current (mA) 0.05 0.2 0.35 TI Information Selective Disclosure

PRAMPS| EE: Infusion Pumps 3: Current sensing Application: ADC Buffer Design Consideration/Challenge Current sense amplifiers usually have a wide range of currents they sense and output voltages. For this reason a RRIO amplifier is necessary to ensure there is no cutoff. To maintain signal integrity a low offset voltage is necessary. Key Features & Product Highlights Texas Instruments low voltage portfolio is built to work beyond the rail to ensure accuracy in your current sensing system. They are also designed to give the lowest offsets to ensure high accuracy. Zero-drift Low power High precision Low bias Low power Low bias Useful reference designs and collateral Specifications OPA391 OPA392 OPA333 1.7 5.5 1.7 - 5.5 1.8 5.5 Supply Voltage (V) Offset Correction Methods: Laser Trim, e-Trim Chopper , and Vos max (mV) 0.045 0.01 0.01 GBW (MHz) 1 13 0.35 Circuit Cookbook Slew Rate (V/ s) 1 4.8 0.16 The Signal e-book: A compendium of blog posts on op amp design topics Rail-to-Rail In, Out In, Out In, Out Bias Current (pA) (Max) 0.8 0.8 130 Output Current (mA) 60 65 5 TI Information Selective Disclosure 4