Utilizing Local Wood for Economic Benefits in ILC Facilities Building

Explore the economic ripple effect of utilizing local wood in the construction of facilities for the International Linear Collider (ILC) experiment, highlighting the efforts by Shelter Co., Ltd., Iwate University, and the Iwate Prefectural Office in Japan. Discover the sustainable practices, urban forestry concepts, and the integration of wooden architecture in creating a green ILC city. Embrace the importance of locally produced wood, laminated timber production, and smart city initiatives for a more sustainable future.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

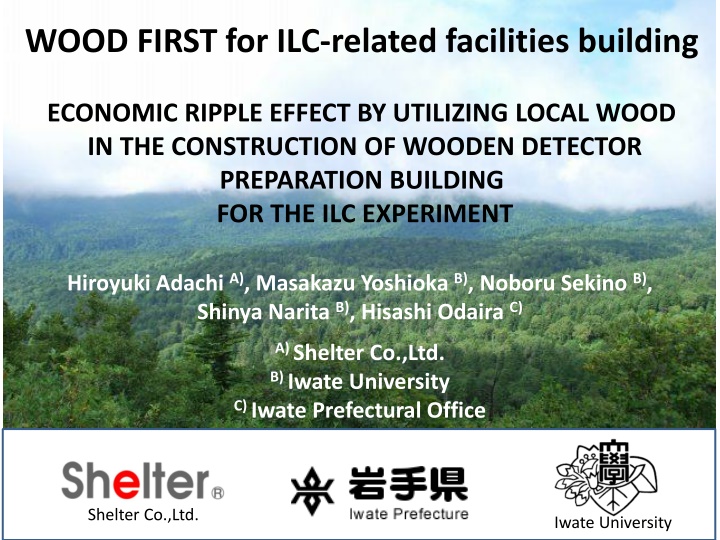

WOOD FIRST for ILC-related facilities building ECONOMIC RIPPLE EFFECT BY UTILIZING LOCAL WOOD IN THE CONSTRUCTION OF WOODEN DETECTOR PREPARATION BUILDING FOR THE ILC EXPERIMENT Hiroyuki Adachi A), Masakazu Yoshioka B), Noboru SekinoB), Shinya Narita B), Hisashi OdairaC) A) Shelter Co.,Ltd. B) Iwate University C) Iwate Prefectural Office Shelter Co.,Ltd. Iwate University

Forest rate in Japan is the world's second largest Forest rate (%) 80 70 60 50 40 30 Horyuji Temple, the world's oldest wooden five-storied pagoda (built in A.D.607) 20 10 0 Forest area (10 ha) 30,000 25,000 20,000 15,000 10,000 5,000 0 Organization for Economic Co-operation and Development, OECD data

The Shelter Corporation imagines a world of urban forests - cities formed of timber-framed buildings. In our architectural and urban planning, we study and research our environment and environmental issues. Shelter Co.,Ltd. Examples of Shelter s work: Town hall in Nan-yo city of Yamagata Prefecture 3

Locally produced wood Laminated timber production by local companies Construction by local companies Number of seats: 1403 H W D Floor area 4

IWATE Prefecture

Green ILC city concept Green ILC EMS network Supply and demand Heat consumer Green ILC city concept is based on 6 points. Heat supply business adjustment ILC energy center Waste heat tank Chilled water tank Agriculture - The research facilities will be built based on international consensus that pursue sustainability. heat Heat supply Storage HASClay Storage Heat supply - Second, we aim to realize a smart city that is based Green ILC. Industrial park Chilled water Greenhouse - A network of heat users will be built. Hot water - Community facilities for ILC related researchers and engineers, are also based on wooden architecture. CHP Hot water ILC campus - A system to circulate local resources and funds by local companies. Chilled water CHP - We make smart city that can enrich whole area by establishing recycling-base society. http://www.illust-box.jp/db_img/sozai/00006/62464/thumb_20170103222525_586ba6458e80f.png Hospital and/or welfare facility Hot water Energy center Heat consumer area Information/commu -nication

Surface facility A site specific design PM-10 electron linac PM-8 Linac and damping ring surface facilities 1.7 Ha 5point Collision point ~8 Ha Interaction Region damping ring PM+8 river positron linac PM+10 7

Precedents: SLS, Swiss Light Source, PSI Shelter s experiences Adopt the KEK-ATF hall for a case study 50m 120m (6000m2) Hybrid of wooden and reinforced concrete or steel frame and RC Same specifications, conditions

Hybrid of wooden and reinforced concrete

Hybrid of steel frame and reinforced concrete

Estimation of direct expenses and primary economic ripple effect 2,500,000 167.8% (10 JP-Yen) 2,000,000 83.7% Primary economic ripple effect Secondary economic ripple effect unit k-Jap.Yen Direct expenses 1,500,000 K-JPY Wood 1,000,000 Steel Wood 1,793,608 2,208,182 231,519 Steel 2,143,653 1,315,845 169,496 500,000 136.3% G/S(%) W/S (%) Yen 83.7 167.8 136.6 0 Direct expenses Primary Secondary economic ripple effect economic ripple effect

Induced employment(person) and induced employees(person shown in parentheses) Employer-induced effect Primary effect Secondary effect Total The number of employed persons Number of employees in employed person The number of employed persons Number of employees in employed person 155 18 173 Gluelam 128 15 143 90 10 100 Steel 78 7 85

Summary of economical ripple effect Direct expenses Wood (17.9 Billion yen) is 83.7% of Steel (21.4 Billion yen) Economical ripple effect Wood (2.2 Billion yen) is 167% of Steel (1.3 Billion yen) Employer-induced effect Wood (173 person) is 174 % of Steel (100 person) These are the results of following: Locally produced wood Laminated timber production by local companies Construction by local companies

Conclusions Wood + RC can have the same quality with Steel + RC such as strength, required construction period, and etc.. In addition, wooden building is friendly to people. Direct expenses of Wood +RC is 16.3 % cheaper than Steel + RC . The steel price is not stable in Japan, because of the large amount of steel frame will be required in near future in Iwate for the semiconductor companies. Local industries are the main player of this business. The policy of WOOD FIRST is very friendly for the local society because of the economical ripple effect and Increase of employment. Increase in timber demand is increasing the number of unused biomass, which is important for Green ILC strategy

We have been also working to make an urban design for ILC researchers, engineers and their families from all over the world. All houses will be made of local timbers by local companies. Thank you for your attention