Understanding Metal Alloys and Carbon Composition in Metals

Metal alloys play a crucial role in various industries with different compositions like ferrous and nonferrous metals. Carbon content determines the properties of steels, from low to high carbon content. Each type has specific characteristics and applications in different sectors, offering diverse mechanical and structural qualities. Understanding these alloy compositions is essential for choosing the right material for specific applications.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

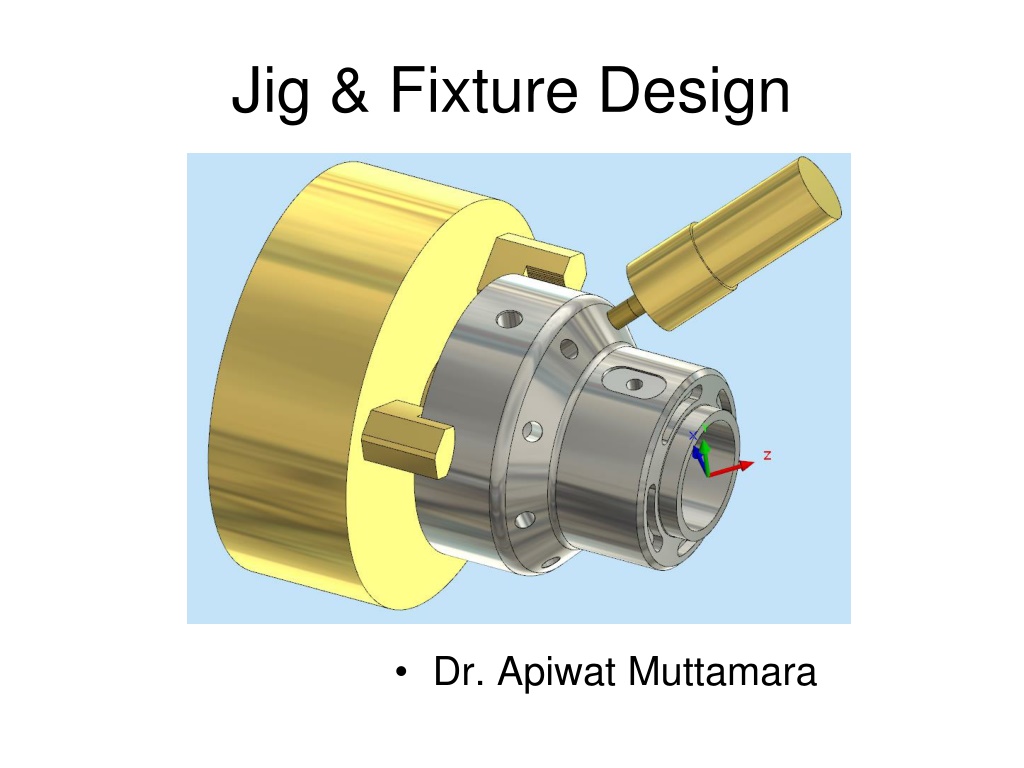

Jig & Fixture Design Dr. Apiwat Muttamara

apron Centre Lathe

CERMET Ceramic+metal

INSERTENDMILL INSERTENDMILL mits-banner

Gear Cutting INDEXING HEAD

Work Holding Method vice

Dial gauge The accuracy of dial 0.010 mm. It is usually used for calibration of machine.

Classifications of Metal Alloys Metal Alloys Metal Alloys Ferrous Nonferrous Steels Steels Steels Cast Irons Cast Irons Cast Irons Cu Al Mg Ti <1.4wt%C <1.4wt%C 3-4.5 3-4.5 wt%C wt%C Ferrous alloys: iron is the prime constituent -Alloys that are so brittle that forming by deformation is not possible ordinary are cast

Percent of carbon in Iron Iron with controlled amounts of carbon. Steels are classified by their carbon content. Designation Wrought Iron Low Carbon Medium Carbon High Carbon Very High Carbon Gray Cast Iron % Carbon .02 - .03 .05 - .30 .30 - .45 .45 - .75 .75 - 1.00 1.7 - 4.5 Steel

Summary: Steels Low-Carbon Steels Properties: nonresponsive to heat treatments; weak; machinable and weldable. Typical applications: automobile bodies, structural shapes, pipelines, buildings, bridges, and tin cans. Medium-Carbon Steels Properties: heat treatable, relatively mechanical characteristics. Typical applications: railway wheels and tracks, gears, crankshafts, and machine parts. High-Carbon Steels Properties: hard, strong, and relatively brittle. Typical applications: chisels, hammers, knives, and hacksaw blades. High-Alloy Steels (Stainless and Tool) Properties: hard and wear resistant; resistant to corrosion in a large variety of environments. Typical applications: cutting tools, drills, cutlery, food processing, and surgical tools. relatively soft and large combinations of

Standards Designation Equivalent of Tool Steels --- American Iron & Steel Institute AISI Japanese Industrial Standards JIS Deutsches Institut f r Normung (German Standards Institute) DIN Svensk Standard (Swedish Standard) SS British Standards BS

DAIDO BRAND JIS AISI DIN YK30 SKS93 - - - YK4 SK4 W1/W2 C100W1 1.154 G0A SKS3mod. - - - Cold Work Tool Steels G05 - - - - X165CrMo V12 DC11 SKD11 D2 1.2379 SKD11mod . DC53 - - - X40CrMoV 51 DHA1 SKD61 H13 1.2344 Hot Work Tool Steels SKD61mod . DH2F - - - 55CrNiMoV 6 GFA SKT4mod. L6 1.2714

DAIDO BRAND JIS AISI DIN 1.3343 MH51 SKH51 M2 S6-5-2 High Spee d - - - - MH85 Tool Steels - - - - PXZ p20mo - - - PX4 d. p20mo - - - PX5 Plastic Mold Steels d. - - - - - - - - NAK55 NAK80 SUS420J2 mod. - 1.4034 S-STAR 420mod. X40Cr13 - - - G-STAR

Recommended DAIDO BRAND Usual General Uses Hardnes s HRC Application Short Life Long Life 58-62 Trimming Dies YK30 GOA 58-63 Pressing Dies YK30 GOA 58-63 Crimping Dies GOA DC11 55-62 Extrusion Dies GOA DC11 55-62 Extrusion Punches GOA DC11 60-65 Brick Forming Dies GOA DC11 58-62 Powder Compacting Dies GOA DC11 60-64 Cross Punches MH51 MH51 56-60 - Plastic Mold Dies GOA

Characteristics of Tool Material Hot Hardness the ability to retain its hardness at high temperatures. Strength and Resistance to Shock At the start of a cut the first bite of the tool into the work results in considerable shock Low Coefficient of Friction

Tool Materials in Common Use High Carbon Steel Contains 1 - 1.4% carbon with some addition of chromium and tungsten to improve wear resistance. The steel begins to lose its hardness at about 250 C, and is not favoured for modern machining operations where high speeds and heavy cuts are usually employed. High Speed Steel (H.S.S.) Steel, which has a hot hardness value of about 600 C, commonly used for single point and multi point cutting tools Cemented Carbides (WC-Co) An extremely hard material made from tungsten powder. Carbide tools are usually used in the form of brazed or clamped tips HSS may be readily machined using carbide tipped tool. High cutting speeds may be used and materials difficult to cut with HSS

Alloying compositions of common high speed steel grades ( by %wt) Grade. C Cr Mo W V Co Mn Si 0.95 4.2 5.0 6.0 2.0 - - - M2 1.00 3.8 8.7 1.6 2.0 - - - M7 0.94 4.1 5.0 6.0 2.0 5.0 - - M35 1.10 3.8 9.5 1.5 1.2 8.0 - - M42