Understanding Melt Spinning in Polymer Fiber Manufacturing

Melt spinning is a specialized extrusion process used for manufacturing polymer fibers at industrial scales. It involves melting the fiber-forming substance, extruding it through a spinneret, solidifying the filament, and applying spin finish. The method allows for shaping fibers in various cross-sectional forms like round, trilobal, pentagonal, and octagonal, each offering unique properties to the resulting textiles. Melt spinning offers advantages such as high production speed and low investment costs, but it also has drawbacks like requiring a separate drawing step and potential damage to some polymers due to high temperatures.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

MELT SPINNING Dr Shama Sadaf Home Economics Department Lahore College for Women University Lahore

SPINNING Spinning is manufacturing process for creating polymer fibers. It is a specialized form of extrusion that uses a spinneret to form multiple continuous filaments. There are three types of spinning Wet Dry Melt spinning

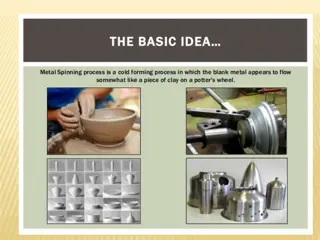

MELT SPINNING Melt spinning is the most convenient and economic method for polymer fiber manufacturing at industrial scales. Melt spun fibers can be extruded from the spinneret in different cross-sectional shapes (round, trilobal, pentagonal, octagonal, and others). Trilobal-shaped fibers reflect more light and give an attractive sparkle to textiles. Pentagonal-shaped and hollow fibers, when used in carpet, show less soil and dirt. Octagonal-shaped fibers offer glitter-free effects. Hollow fibers trap air, creating insulation and provide loft characteristics equal to, or better than, down.

PROCESS . In melt spinning, the fiber-forming substance is melted for extrusion through the spinneret and then directly solidified by cooling Finally, spin finish is applied before the filament bundles are wound on tube rolls.

ADVANTAGES Can be used for both staple and continuous filament No environment pollution High production speed (2500-3000) ft/min Low investment cost

DISADVANTAGES Separate drawing step (unless spin draw) Necessary high temperature may damage some polymers