Exploring the Potential of Natural Fiber Reinforced Polymer Composites (NFRPC)

Natural fiber reinforced polymer composites (NFRPC) are sustainable materials that utilize renewable natural fibers as reinforcement for polymer matrices. They offer high performance, environmental benefits, and versatile applications in industries such as automotive, aerospace, construction, and electronics. The market for NFRPC is growing rapidly, driven by government regulations and the increasing demand for green composites. Various key players are contributing to the industry's growth, making NFRPC a promising area for exploration and development.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

SAMPLE LANDSCAPE STUDY Natural Fiber Reinforced Polymer Composites (NFRPC)

Contents Introduction to NFRPC and Applications Growth Prospects of NFRPC Evolution of Natural Fiber Composites Key Developments - NFRPC Objectives for the Landscape Study Trend Analysis and Graphical Representation Key Technology Trends Patent Portfolio Analysis Technological Dissection of Patent Portfolio and Analysis of Key Granted Patents Analysis of Key Granted Patents Assigned to Educational Institutes and Universities Appendix A Sources Appendix B Definition of IPC Classes 2

Introduction to NFRPC and Applications Introduction Natural fiber reinforced polymer composites (NFRPC) are the materials where renewable natural o fibers (such as hemp, sisal, jute, kenaf, flax, etc.) are used as reinforcing material (fillers) for different kind of polymer matrices (thermoplastics, thermosettings, and biopolymers) to obtain high performance composites. NFRPC materials recently became highly valuable materials since the reuse of waste natural fibers o as reinforcement for polymer is sustainable option to the environment. The natural fibers have the advantage that they are renewable resources and have marketing o appeal as they are cheap, renewable, partially recyclable and biodegradable. Applications As environmentally attractive materials, natural fiber composites have been proven as an alternative o to the glass reinforced or carbon reinforced polymer composites that can utility in different applications like automotive, aerospace, construction, packaging, electronics, sports etc. For sources of information, please refer to Appendix 1 3

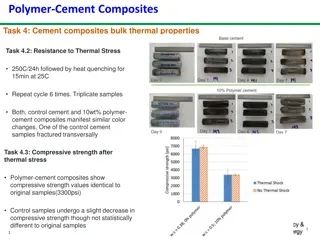

Growth Prospects for NFRPC The NFRPCs market was worth USD 3.36 Billion, in 2015, and is projected to reach USD 6.50 Billion in 2021, expected to register a CAGR of 11.68% between 2016 and 2021. Government regulations and huge demand of green composites will drive the NFRPC s market. North America dominated the global NFRPCs market in 2017 followed by Asia-Pacific and Europe and is expected to dominate the market during 2018-2023 due to high demand from the construction industry. The market dominance of the non-wood fiber segment is due to widespread applications of the bast fibers (flax, hemp, kenaf, jute, mesta, ramie, rosella, isora). Germany is one of the largest producers of automobiles and a major importer of hemp in Europe. China dominated the Asia Pacific market and is likely to continue dominance over the coming years. The companies in the industry are highly integrated from the manufacturing to distribution of finished products to various locations. Advanced Environmental Recycling Technologies, Inc. (U.S.), FlexForm Technologies (US), Procotex Sa Corporation Nv (Belgium), Tecnaro Gmbh. (Germany), UPM Biocomposites (US), and Trex Company, Inc (US) are some of the key players in the industry. For sources of information, please refer to Appendix 1 4

Evolution of Natural Fiber Composites For sources of information, please refer to Appendix 1 5

Key Developments - NFRPC Henry Ford developed Global NFRPC market reached World s first car made from NFRPC Plant based car $4.46 B First time in world, NFRPC was used for a mobile phone casing - Model Name: FOMA(R) N701iECO 2017 2016 2010 2008 2006 1942 Ford Motors innovated a car trim bin for it s Ford Flex CUV model Museeuw Bikes has developed first racing bike with flax epoxy NFRPC For sources of information, please refer to Appendix 1 6

Objectives of the Landscape Study To understand technology and prepare patent landscape To understand major patent holders, geographical distribution of patents, top sub- technologies based on IPC codes Analysis of patent filing trends over the years, top assignees, top patent classifications, among others To conduct Patent Portfolio based study of patents relating to core focus area of NFRPC in the patents/ applications Assumptions: Report provides patent analysis for NFRPC market, which includes study of synthetic processes of NFRPC and advance technology based patents. The landscape study focuses on patents pertaining to NFRPC s filed between 1998-2018. 7

Trend Analysis and Graphical Representation Patent Searching | Research and Analytics | Patent Prosecution/Preparation Support | Litigation and E-Discovery | IP Valuation | Patent Portfolio Watch

Filing Trends Last 20 Years 40 36 33 OTHERS, 31 35 30 KR, 12 Number of Patent Families 30 JP, 17 IN, 18 25 CN, 150 21 20 EP, 18 19 20 21 US, 26 15 16 12 10 8 10 6 6 5 5 5 5 4 3 3 5 4 0 Application Year Insights Global patent filing trend analysis shows an overall rise in the number of patent applications filed in last 20 years. There is significant rise in the no. of patent applications filed from the year 2010 with highest filing in the year 2012 followed by a dip during 2013-2015. Maximum number of applications were filed from CN, followed by US and EP jurisdictions. 9

Publication Trends - Last 20 Years 60 54 50 Number of Patent Families 40 34 30 24 23 23 19 17 20 16 10 10 8 10 6 5 5 4 4 3 3 3 1 0 Publication Year Insights Global patent publication trend presents a overall rise in the number of publications during last 2 decades with its peak during 2017, which suggests significant filing during 2014-2016. Total number of patents/applications published in 2018 may increase till the end of the year. 10

Top Assignee 8 8 7 7 Number of Patent Families 6 6 5 5 4 4 4 4 4 4 4 3 2 1 0 Assignee Insights Zhibang Kitchen Cabinet Co Ltd is the leading patent applicant in NFRPC materials production domain, followed by Shanghai Genius Advanced Mat and University of Tongji. 11

Top International Patent Classifications (IPCs) Others, 75 B29C, 27 C08J, 29 C08L, 106 Others, 10 B32B, 32 C08L002312 , 26 Others, 40 Others, 16 C08J000504, 3 C08J000504 , 12 C08L002706 , 5 C08J000506 , 4 C08L009702 , 16 C08L006704 , 19 B32B002712 , 3 B32B000902 , 10 Insights B32B002704 , 3 Maximum number of applications filed during 1998-2018 corresponds to IPC class C08L relating to Composition of Macromolecular Compounds . Amongst applications filed in C08L, majority of applications were filed in technology of sub-class C08L 23/12 which relates to Polypropene . Second highest number of applications were filed in the technology covered by IPC class B32B which relates to Layered products, i.e. Products Built-up of Strata of Flat or Non-flat, e.g. Cellular or Honeycomb, form. Amongst applications filed in B32B, 30% of applications were filed in technology of sub-class B32B 09/02 which relates to the Comprising animal or Vegetable substances . Third highest number of application were filed in the technology covered by IPC class C08J which related to Working Up; General Process of Compounds; . 12 # For IPC sub-class definitions please refer to Appendix 2.

Geographic Origin of Innovation OTHERS 22 FR 6 EP 6 KR 13 Jurisdiction US 13 IN 17 JP 21 DE 26 CN 148 0 20 40 60 80 100 120 140 160 Number of Patent Families Insights Analysis of Geographic Origin of Innovation (i.e. priority country) demonstrates that maximum number of innovations originated from CN followed by DE and JP jurisdictions. 13 Patent Searching | Research and Analytics | Patent Prosecution/Preparation Support | Litigation and E-Discovery | IP Valuation | Patent Portfolio Watch

Key Technological Trends Patent Searching | Research and Analytics | Patent Prosecution/Preparation Support | Litigation and E-Discovery | IP Valuation | Patent Portfolio Watch

PATENT FOCUS AND APPLICATION AREA 5 Marine 6 Packaging 7 Sports 206 14 Aerospace 74 31 Others 36 Construction Process Product 40 Wood Subsitute 132 Automobiles 0 50 100 150 Insights Maximum percentage of applications (73%) were focused on technological process of NFRPC production. 48% of patents are related to automobiles sector followed by wood substitute products for homes and kitchen and materials used in construction. 15

Natural Fiber and Polymer Type Cotton, 10 Generic, 47 Polyethylene, 29 Flax, 42 Generic, 61 Others, 28 Hemp, 53 Others, 60 ABS, 4 Polypropylene, 94 Jute, 36 Polyester, 34 Sisal, 23 Polylactic acid , 10 Kenaf, 16 Polyamide, 6 HDPE, 33 Bamboo, 78 Insights Maximum applications (71%) were filed where materials are produced using bamboo as natural fiber followed by generic fibers and hemp. Polypropylene is the polymer matrix that is used in highest no of patents to produce NFRPC followed by Polyester and Polyethylene . 16

Patent Portfolio Analysis Patent Searching | Research and Analytics | Patent Prosecution/Preparation Support | Litigation and E-Discovery | IP Valuation | Patent Portfolio Watch

Patent Portfolio Analysis GENIUS Company Profile CN104228237A CN103374166B CN102953231B CN103571038B CN102477170B Shanghai Genius Advanced Material (Group) Co., Ltd. is CN104228237A Natural Fibre- Polypropylene/ Polyethylene/ Polyester CN103374166B a company dedicated to engineering plastics, advanced CN102953231B composite materials, polymer research & development, CN103571038B and manufacturing. CN102477170B Product Dissection of Patent Portfolio CN103965515A CN103374220B Natural Fibre/ Other Polymers CN103965515A CN103374220B Natural Fibre/Polypropylene/Pol yEthylene/PolyEster 29% 71% NF = Cotton, Flax, Hemp, Jute, Bamboo, Sisal, Kenaf etc. Natural Fibre/Other Polymers 18

Patent Portfolio Analysis GENIUS Application-wise Dissection of Patent Portfolio CN103374166B CN103374220B CN102953231B CN103374166B Automobiles CN103374220B CN102953231B CN104228237A CN102477170B CN103965515A CN103571038B CN104228237A CN102477170B Others CN103965515A CN103571038B 43% Automobiles 57% Others 19

Patent Portfolio Analysis GENIUS Key Patents: Patent No. Key Features US7741389B2 Resin composition containing a polyalkylene furan dicarboxylate resin and a porphyrin compound US8981037B2 PEF used in preparation of a polyester resin The invention belongs to the technical field of composite processing, and relates to a natural fiber- reinforced thermoplastic composite material prepreg tape, and a preparation method thereof. The prepared natural fiber/thermoplastic resin skateboard surface can be stored for a long time, and after hot press, the natural fibers can be impregnated by the resin thoroughly, so that the material particularly the natural fibers can be kept dry. The natural fibers are not liable to mildew or deteriorate. Products adopted by the invention have no harm to a human body and do not produce adverse reaction. The present invention belongs to the technical field of composite materials, relates to a thermoplastic composite material and its preparation method and uses. The present invention is the composite material prepared environmental performance, degrade naturally; a certain mechanical strength to meet the strength requirements for automotive interior materials; in addition, the composite material as well as good processability and safety; Further, the present invention shorten the process and improve the production efficiency; more important is to achieve a light-weight and green automotive interior materials. The present invention discloses a fully biodegradable fiber reinforced starch, natural plant-based composite material and its preparation method, belongs to the technical field of polymer materials. Composite of the invention comprises the following components: 10-60wt% of natural vegetable fibers, 10-25wt% starch, 20- 50wt% of an aliphatic polyester, 10-20wt% starch compatibilizer. The composite material of the present invention has excellent moldability, processability type, acid, alkali, and water having a high strength and modulus, and can be completely natural biodegradable CN104228237A US20120258299 PEF is used in preparation of a polyester resin CANON CN102953231B CN102477170B 20 Patent Searching | Research and Analytics | Patent Prosecution/Preparation Support | Litigation and E-Discovery | IP Valuation | Patent Portfolio Watch

Patent Portfolio Analysis CHANGCHUN BOCHAO AUTOMOBILE PARTS CO LTD Company Profile CN108018665A CN106476356A Changchun Bo Chao is one of the key CN108018665A Process CN106476356A enterprise which has achieved the ability of producing high-surface-density natural fiber composite materials in China. It has become CN108099298A CN206277734U CN108099298A Product the preferred natural fiber material supplier of CN206277734U composites-producing companies. Low- Pressure-Natural-Fiber, an absolutely environment friendly material with features of Technological Dissection of Patent Portfolio renewable natural fiber reinforced, supper machinability, wide applications. 50% 50% Process Product 21

Patent Portfolio Analysis CHANGCHUN BOCHAO AUTOMOBILE PARTS CO LTD Product wise Dissection of Patent Portfolio CN106476356A CN206277734U CN106476356A NF/Polyurethane CN206277734U 50% 50% NF/PolyUrethane CN108099298A CN108018665A CN108099298A NF/Others CN108018665A NF/Others NF = Cotton, Flax, Hemp, Jute, Bamboo, Sisal, Kenaf etc Application-wise Dissection of Patent Portfolio Automobiles CN108099298A CN108018665A CN106476356A CN206277734U CN108099298A CN108018665A 100% Automobiles CN106476356A CN206277734U 22

Patent Portfolio Analysis CHANGCHUN BOCHAO AUTOMOBILE PARTS CO LTD Key Patents: US7741389B2 Resin composition containing a polyalkylene furan dicarboxylate resin and a porphyrin compound US8981037B2 PEF used in preparation of a polyester resin Patent No. Key Features The present invention discloses a species of formaldehyde and acetaldehyde released natural hemp fiber polymer matrix composites reinforced felt material and its preparation method, belonging to the field of design and manufacture of automotive materials. Polymer is a polymeric fibers may be polypropylene PP, polyethylene PE, polycarbonates PC, nylon 6PA6, nylon 66PA66 or polylactide (or polylactic acid) PLA. CN108099298A US20120258299 PEF is used in preparation of a polyester resin EP2257596B1 Resin composition containing polyethylene furandicarboxylate CANON The invention provides a fibrilia enhanced polyurethane composite board and a preparation method thereof, and belongs to the field of automobile material design and manufacturing. The present invention proposes to add a hemp fiber reinforced polyurethane between the double skin panel as the intermediate layer, to achieve a new type of hemp fiber reinforced polyurethane composite panels. The preparation method comprises the following steps: firstly, laying a refinedly opened fibrilia felt on one panel layer; then, spraying the polyurethane on the fibrilia felt; next, laying the other panel layer on the polyurethane; then, heating, shaping and cooling to obtain a product. EP2235100B1 Resin composition containing polyethylene furandicarboxylate CN106476356A US20090124763 Method of synthesis, PEF having a furan ring 23 Patent Searching | Research and Analytics | Patent Prosecution/Preparation Support | Litigation and E-Discovery | IP Valuation | Patent Portfolio Watch

Patent Portfolio Analysis- Faurecia Company Profile is the 6th largest international Faurecia automotive parts manufacturer in the world; in 2013 it was #1 for vehicle interiors and emission control technology. One in four automobiles is equipped by Faurecia. manufactures seats, exhaust systems, interior systems (dashboards, centre consoles, door panels, acoustic modules) and decorative aspects of a vehicle (aluminum, wood). US9951215B2 US9446723B2 US9951215B2 Process US9446723B2 It designs and WO2013026571A1 FR2979871A1 WO2013026571A1 Product FR2979871A1 Technological Dissection of Patent Portfolio 50% 50% Process Product 24 Patent Searching | Research and Analytics | Patent Prosecution/Preparation Support | Litigation and E-Discovery | IP Valuation | Patent Portfolio Watch

Patent Portfolio Analysis Faurecia Key Patents: Patent No. Key Features The invention relates to an injectable composite material comprising: (a) 28 to 95% by weight of a polypropylene-polyethylene copolymer; (b) 0 to 10% by weight of a flow enhancer; (c) 1 to 20% by weight of an impact modifier; (d) 1 to 20% by weight of a compatibilizing agent; and (e) 3 to 70% by weight of natural fibers, wherein the polypropylene-polyethylene copolymer forms a matrix. It also relates to a method for preparing this composite material as well as to a method for its use for manufacturing parts by injection or by over molding. US9951215B2 25 Patent Searching | Research and Analytics | Patent Prosecution/Preparation Support | Litigation and E-Discovery | IP Valuation | Patent Portfolio Watch

Analysis of Key Granted Patent Assigned to Educational Institutes and Universities Patent Searching | Research and Analytics | Patent Prosecution/Preparation Support | Litigation and E-Discovery | IP Valuation | Patent Portfolio Watch

Granted Patents Analysis Institutes & Universities Patent No. Key Features The present invention belongs to the field of materials technology, relates to a flame retardant natural fiber-reinforced polylactic acid and its preparation method, the resulting material has good mechanical properties and flame retardant properties, can be used in electrical and electronic packaging. In the present invention, said natural fibers are ramie fibers, jute fibers, flax fibers, hemp fibers, kenaf fibers, sisal fibers, bamboo fibers, or one or more. The invention belongs to the technical field of material, and specially relates to a natural fiber reinforced polylactic acid composite material with a halogen-free flame retardant and a method for preparing the same. The preparation method comprises proportionately mixing the dried polylactic acid, the flame retardant, an anti-oxidant, a compatibilizer and an anti-dripping agent, adding the mixture and a natural fiber into an extruder in accordance with a certain proportion, and then extruding with blending to get the natural fiber reinforced polylactic acid composite material with the halogen-free flame retardant. In the present invention, the natural fiber is one or more ramie fibers, jute fibers, flax fibers, hemp fibers, kenaf fibers, bamboo, or sisal fibers. The present invention belongs to the technical field of materials, particularly relates to a method for preparing a phenolic resin composite material, a flame retardant DOPO modified natural fiber- reinforced. A flame-retardant reinforced by natural fibers DOPO modified phenolic resin prepared composite material, characterized by the following steps: (1) the amount of DOPO by adding a solvent to prepare a mass fraction of DOPO f 40% of solution; (2) after the natural fibers and baked at 10 C ~160 C 0. 24 sealed hours; (3) the step (2) was immersed in a natural fiber obtained in step (I) formulated solution for DOPO retardant modification, `0. 48 hours after extraction of natural fibers, DOPO prepared mass content of natural fiber is 0.19 50%; after (4) step (3) treatment of natural fibers in the resulting flame 10 drying under C ~120 C 0. 24 hours; (4) obtained in (5) the step of natural fibers and phenolic resin weight ratio of 1: 9,: I uniformly compound prepared prepreg; (6 ) of step (5) to give the natural fiber prepreg of phenolic resin into the mold, the resin composite material reinforced phenolic composites by hot pressing retardant modified process for preparing natural fiber; wherein: said natural fibers are ramie fibers, flax, kenaf, sisal, jute or hemp fibers To several; the phenolic resin is a thermosetting phenolic resin. CN102757628B University of Tongji US7741389B2 Resin composition containing a polyalkylene furan dicarboxylate resin and a porphyrin compound US8981037B2 PEF used in preparation of a polyester resin CN102746625A University of Tongji US20120258299 PEF is used in preparation of a polyester resin EP2257596B1 Resin composition containing polyethylene furandicarboxylate CANON EP2235100B1 Resin composition containing polyethylene furandicarboxylate US20090124763 Method of synthesis, PEF having a furan ring CN102417691B University of Tongji EP2252645B1 Polyester resin used for producing a molded article 27 Patent Searching | Research and Analytics | Patent Prosecution/Preparation Support | Litigation and E-Discovery | IP Valuation | Patent Portfolio Watch

Granted Patents Analysis Institutes & Universities Patent No. Key Features US7741389B2 Resin composition containing a polyalkylene furan dicarboxylate resin and a porphyrin compound US8981037B2 PEF used in preparation of a polyester resin The object of the present invention is to provide the compatibility interface between a modified epoxy monomer bamboo fiber reinforced unsaturated polyester (UPE) composite material and its preparation method to improve the UPE bamboo fiber and resin matrix, enhance the bamboo fiber / UPE overall performance of the composite. Bamboo fiber of the present invention prepared UPE reinforced composite material having a higher tensile strength, flexural strength and flexural modulus, impact strength and no significant reduction. CN105111478B Fujian Agriculture and Forestry University US20120258299 PEF is used in preparation of a polyester resin EP2257596B1 Resin composition containing polyethylene furandicarboxylate The present invention discloses a plasma modified bamboo fiber reinforced unsaturated polyester composite material and its preparation method using plasma technology to the original bamboo fiber surface modification, the modified bamboo fiber, unsaturated polyester resin, cross- linking agents, accelerators and initiators obtained by compression molding the modified bamboo fiber reinforced unsaturated polyester composites. Plasma modification bamboo fiber prepared according to the invention enhances the strength and flexural modulus of unsaturated polyester composites have good tensile strength, bending. CANON CN103497495B Fujian Agriculture and Forestry University EP2235100B1 Resin composition containing polyethylene furandicarboxylate US20090124763 Method of synthesis, PEF having a furan ring 28 Patent Searching | Research and Analytics | Patent Prosecution/Preparation Support | Litigation and E-Discovery | IP Valuation | Patent Portfolio Watch

Granted Patents Analysis Institutes & Universities Patent No. Key Features US7741389B2 Resin composition containing a polyalkylene furan dicarboxylate resin and a porphyrin compound A method of making a natural fiber composite panel, comprising the steps of:(a) treating a plant source comprising natural fibers with a solvent; (b) processing the treated plant source including arranging the natural fibers into a sheet-like orientation; and (c) forming a completed composite sheet by applying a polymeric material to the arranged natural fibers. US8981037B2 PEF used in preparation of a polyester resin US20150041081A1 University of Michigan US20120258299 PEF is used in preparation of a polyester resin The present invention relates to a thermoplastic polymer composition reinforced with natural fibers such as cellulose or other fillers and to a process for manufacturing the composition. The process for making a naturally derived fiber-reinforced thermoplastic polymer composition comprises melting a high melting temperature thermoplastic polymer, mixing the melted thermoplastic polymer with an organic or inorganic salt to reduce the melting temperature of the melted thermoplastic polymer to a melting temperature which does not degrade the natural fibers, and then adding the naturally derived fibers to produce the naturally derived fiber- reinforced thermoplastic polymer composition. The naturally derived fiber-reinforced thermoplastic polymer composition can then be melted at the reduced melting temperature to manufacture a plurality of articles. EP2257596B1 Resin composition containing polyethylene furandicarboxylate CANON US20050013982A1 University of Michigan EP2235100B1 Resin composition containing polyethylene furandicarboxylate US20090124763 Method of synthesis, PEF having a furan ring EP2252645B1 Polyester resin used for producing a molded article 29 Patent Searching | Research and Analytics | Patent Prosecution/Preparation Support | Litigation and E-Discovery | IP Valuation | Patent Portfolio Watch

Granted Patents Analysis Other Companies Patent No. Key Features A reinforced organic natural fiber composite material having a lambda value in the range 15-35 mW/mK, said composite material comprising:25-85% by weight of hydrophobic nanoporous particles calculated on the total weight of the composite material, and at least 10% by weight of organic natural fibers having isocyanate reactive groups calculated on the total weight of the composite material, and 1-15% by weight of binder calculated on the total weight of the composite material, wherein, the binder is a polyurea/polyurethane binder made from emulsifiable polyisocyanate, water, and surfactants. US7741389B2 Resin composition containing a polyalkylene furan dicarboxylate resin and a porphyrin compound US8981037B2 PEF used in preparation of a polyester resin US9988504B2 Huntsman A natural fiber-reinforced acrylonitrile - butadiene - styrene copolymer composite materials made from main material and made by parts by weight, wherein: said Ingredients prepared from the following components in parts by weight to: acrylonitrile - butadiene - styrene copolymer, 75~90 parts, 5~20 parts natural hemp fibers, toughening ~ 5 parts; the total parts by weight to 100 parts of main ingredient as a reference, the materials prepared from the following components in parts by weight from: antioxidant 0.2 parts of lubricant 0.2~0.5 parts. US20120258299 PEF is used in preparation of a polyester resin EP2257596B1 Resin composition containing polyethylene furandicarboxylate CN106700394A EFEI ORINKO NEW MAT CO LTD CANON EP2235100B1 Resin composition containing polyethylene furandicarboxylate CN106189314A ZHIBANG KITCHEN CABINET CO LTD A modified SAN resin bamboo fiber-reinforced composite plate cabinet group, wherein the plastic sheet is made of bamboo or less parts by weight of materials: modified bamboo fiber 50-60, 10-15 metallocene polyethylene elastomer , SAN resins 20-30, maleic anhydride grafted polyethylene 3- 5, 1-2, 0.1-0.2 antioxidants, ionic liquids 5-8, 1-2 methyl acrylate, zinc hydrogenated castor oil. US20090124763 Method of synthesis, PEF having a furan ring EP2252645B1 Polyester resin used for producing a molded article 30 Patent Searching | Research and Analytics | Patent Prosecution/Preparation Support | Litigation and E-Discovery | IP Valuation | Patent Portfolio Watch

Granted Patents Analysis Other Companies Patent No. Key Features The present invention relates to a process for preparing a natural fibre- reinforced composite material and to a radically curable mixture comprising natural fibers. Radically curable mixture comprising a radically curable thermosetting resin, fibers from plants of the Gramineae family, one or more organic peroxides, and optionally fillers, wherein the content of radically curable thermosetting resin in the mixture is in the range 20-50 wt%, the total content of fillers and fibers in the mixture is in the range 50-80 wt%, and wherein the content of fibers from plants of the Gramineae family in the mixture is in the range 5-80 wt% and wherein the total moisture content of the fibers from plants of the Gramineae family is 0.5-25 wt%, based on the total weight of said fibers. US7741389B2 Resin composition containing a polyalkylene furan dicarboxylate resin and a porphyrin compound US8981037B2 PEF used in preparation of a polyester resin WO2017202702A1 (AKZO NOBEL) US20120258299 PEF is used in preparation of a polyester resin The invention relates to natural fiber-reinforced polyisocyanate poly addition products, process for their preparation by reacting polyisocyanates with isocyanate-reactive compounds and optionally chain extenders and / or crosslinkers, catalysts, blowing agents and auxiliaries and / or additives in the presence of natural fibers (sisal fibers with mixtures of jute, hemp and / or flax fibers) and the use thereof. EP2257596B1 Resin composition containing polyethylene furandicarboxylate CANON DE19644017A1 (BASF) EP2235100B1 Resin composition containing polyethylene furandicarboxylate EP2252645B1 Polyester resin used for producing a molded article 31 Patent Searching | Research and Analytics | Patent Prosecution/Preparation Support | Litigation and E-Discovery | IP Valuation | Patent Portfolio Watch

APPENDIX 1: SOURCES https://www.marketsandmarkets.com/Market-Reports/natural-fiber-composites-market- 90779629.html?gclid=EAIaIQobChMI1uzy1e-l3AIVUVmGCh1HDgsNEAAYASAAEgJjLPD_BwE https://www.businesswire.com/news/home/20180509006307/en/Global-Natural-Fiber-Reinforced-Composites-Markets-2023 US7741389B2 Resin composition containing a polyalkylene furan dicarboxylate resin and a porphyrin compound US8981037B2 PEF used in preparation of a polyester resin https://www.grandviewresearch.com/industry-analysis/natural-fiber-composites-market http://tpac.geniuscn.com/about.php http://www.bochaoautoparts.com/en/about/?152.html http://www.faurecia.com/en EP2257596B1 Resin composition containing polyethylene furandicarboxylate https://www.prnewswire.com/news-releases/natural-fiber-composites-market-worth-583-billion-by-2019-285331091.html https://www.slideserve.com/seoras/food-and-agriculture-organization https://www.lucintel.com/lucintelbrief/potentialofnaturalfibercomposites-final.pdf EP2235100B1 Resin composition containing polyethylene furandicarboxylate http://www.roadbikereview.com/reviews/museeuw-flax-carbon-racing-bikes-launched-in-the-us https://www.plasticstoday.com/automotive-and-mobility/worlds-first-car-made-bio-composites-makes-global- debut/191672795856951 EP2252645B1 Polyester resin used for producing a molded article 32 Patent Searching | Research and Analytics | Patent Prosecution/Preparation Support | Litigation and E-Discovery | IP Valuation | Patent Portfolio Watch

APPENDIX 2: DEFINITION OF IPC CLASSES IPC CLASS DEFINITIONS Chemistry; Metallurgy; Their preparation or chemical working-up; compositions based thereon; compositions of macromolecular compounds; organic macromolecular compounds (compositions based on polymerisable monomers; artificial filaments or fibers; textile treating compositions; C08L US7741389B2 Resin composition containing a polyalkylene furan dicarboxylate resin and a porphyrin compound Chemistry; Metallurgy; Their preparattion or chemical working-up; compositions based thereon; compositions of macromolecular compounds; organic macromolecular compounds (compositions based on polymerisable monomers; artificial filaments or fibers; textile treating compositions); Compositions of homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Compositions of derivatives of such polymers; Polypropylene: US8981037B2 PEF used in preparation of a polyester resin C08L 23/12 Chemistry; Metallurgy; Their preparation or chemical working-up; compositions based thereon; compositions of macromolecular compounds; organic macromolecular compounds (compositions based on polymerisable monomers; artificial filaments or fibers; textile treating compositions); Compositions of polyesters obtained by reactions forming a carboxylic ester link in the main chain (of polyester-amides; of polyester-imides); Compositions of derivatives of such polymers; Polyesters derived from hydroxy carboxylic acids, e.g. lactones C08L 67/04 US20120258299 PEF is used in preparation of a polyester resin EP2257596B1 Resin composition containing polyethylene furandicarboxylate Chemistry; Metallurgy; Their preparation or chemical working-up; compositions based thereon; compositions of macromolecular compounds; organic macromolecular compounds (compositions based on polymerisable monomers; artificial filaments or fibers; textile treating compositions); Compositions of lignin-containing (of polysaccharides ); Lignocellulosic materiall, e.g. wood, straw or bagasse; CANON C08L 97/02 Performing Operations; Transporting; Layered Products; Layered Products, I.E. Products Built-up Of Strata Of Flat Or Non-flat, E.G. Cellular Or Honeycomb, Form; B32B Performing Operations; Transporting; Layered Products; Layered Products, I.E. Products Built-up Of Strata Of Flat Or Non-flat, E.G. Cellular Or Honeycomb, Form; Layered Products Essentially Comprising A Particular Substance Not Covered By Groups; Comprising Animal Or Vegetable Substances; EP2235100B1 Resin composition containing polyethylene furandicarboxylate B32B 09/02 US20090124763 Method of synthesis, PEF having a furan ring Performing Operations; Transporting; Layered Products; Layered Products, I.E. Products Built-up Of Strata Of Flat Or Non-flat, E.G. Cellular Or Honeycomb, Form; Layered Products Essentially Comprising Synthetic Resin; As Impregnant, Bonding, Or Embedding Substance; B32B 27/04 EP2252645B1 Polyester resin used for producing a molded article Chemistry; Metallurgy; Their Preparation Or Chemical Working-Up; Compositions Based Thereon; Compositions Of Macromolecular Compounds; Working-up; General Processes Of Compounding; After-treatment Not Covered By Subclasses C08J Chemistry; Metallurgy; Their Preparation Or Chemical Working-up; Compositions Based Thereon; Compositions Of Macromolecular Compounds; Working-up; General Processes Of Compounding; After-treatment Not Covered By Subclasses; Manufacture Of Articles Or Shaped Materials Containing Macromolecular Substances (Manufacture Of Semi-permeable Membranes B01d 67/00-b01d 71/00); Reinforcing Macromolecular Compounds With Loose Or Coherent Fibrous Material C08J 05/04 33 Patent Searching | Research and Analytics | Patent Prosecution/Preparation Support | Litigation and E-Discovery | IP Valuation | Patent Portfolio Watch

Disclaimer IIPRD has prepared this sample report as an exemplary report, wherein the content of the report is based on internal evaluation of Patents and Non-Patent Literature that is conducted based on Databases and Information sources that are believed to be reliable by IIPRD. A complete list of patent documents retrieved is not disclosed herein as the report is exemplary but can be shared if desired based on terms and conditions of IIPRD. IIPRD disclaims all warranties as to the accuracy, completeness or adequacy of such information. The above sample report is prepared based on the search conducted on the keywords and other information extracted from the understanding of the Patent Analysts of IIPRD, and subjectivity of the researcher and analyst. Neither IIPRD nor its affiliates nor any of its proprietors, employees (together, "personnel") are intending to provide legal advice in this matter. 34

ContactDetails CONTACT DETAILS CALIFORNIA . DELHI . NOIDA . MUMBAI . BANGALORE . PUNE . HYDERABAD Contact Details Noida (NCR) Office Head Office E-13, UPSIDC Site-IV, Behind Grand Venice, Greater Noida, 201308 Contact Person: Tarun Khurana Contact No.: +91-120-2342010-11/4296878 E-Mail: iiprd@iiprd.com, info@khuranaandkhurana.com Website: www.iiprd.com | www.khuranaandkhurana.com 35

About IIPRD IIPRD Commercialization/Licensing Firm with a diversified business practice providing services in the domain of Commercialization, Valuation, Licensing, Transfer of Technology and Due-Diligence of Intellectual Property Assets along with providing complete IP and Patent Analytics and Litigation Support Services to International Corporate and Global IP Law Firms. is a premier Intellectual Property Consulting and 36 Office- E-13, UPSIDC, Site-IV, Kasna Road, Greater Noida, National Capital Region - 201308, India ,Phone: +91.120.2342010, 3104849, Fax: 2342011, Website: www.iiprd.com, Email: iiprd@iiprd.com