Understanding Let-off Motion in Weaving: Negative vs Positive Systems

In weaving, let-off motion plays a crucial role in maintaining warp tension. Negative let-off involves pulling warp against a slipping-friction system, while positive let-off rotates the warp beam for tension control. Equation ratios and mechanisms are explained for both systems in detail, highlighting how warp tension is managed effectively in weaving processes.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Beat up Motion Beat up Motion Bumping

Let Let- -off Motion off Motion The objective of let-off motion is to maintain the free length of warp within specified limits and to control the warp tension by means of feeding the warp at a correct rate to the weaving zone. Classification Let-off motion is classified as negative and positive let-off. In case of negative let-off, warp is pulled from the warper s beam against a slipping-friction system. For positive let-off system, warp beam is rotated through driving mechanism at a controlled rate in order to maintain constant warp tension.

Negative Let Negative Let- -Off Off

Negative Let Negative Let- -Off Off the warp is pulled off the warp beam and warp tension is governed by the friction between chain and the beam ruffle. The chain makes some wrap over the ruffle. Slack side of the chain is attached with the machine frame whereas the tight side is attached with the weight lever. The lever is fulcrumed at one end with the machine frame. The other end carries dead weights. Notations: R = radius of warp on the beam r = beam ruffle radius Tt= tension in the chain on tight side (attached with the weight lever) Ts= tension in the chain on slack side (attached with machine frame) W= weight x = the distance between fulcrum point and chain on tight side y = the distance between fulcrum point and weight (variable) T = tension in the warp sheet (variable) F = frictional force at the beam ruffle

Taking moments about the beam centre we have: T R = F r The frictional force F =Tt - Ts where = coefficient of friction between chain and beam ruffle and = angle of wrap in radian made by the chain on beam ruffle. Now, taking moments about the fulcrum H of the lever, we have:

Equation 5 shows that the condition needed to achieve a constant warp tension is to maintain the ratio constant. Thus as beam radius R reduces, the distance y must be reduced by moving the weight towards the fulcrum H in regular interval to balance the warp tension. For example, if the beam radius decreases by 25%, the distance y must be reduced by 25% to maintain a constant warp tension. Positive Let-off In case of positive let-off warp, the warp tension is controlled by a mechanism which drives the warp beam at a correct rate. In most of the positive let-off systems, the backrest is not fixed but floating. It acts as a warp tension sensing mechanism. As the tension in the warp increases, the backrest is depressed.

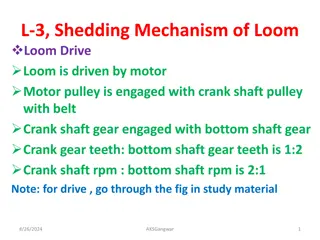

Hunt positive let Hunt positive let- -off motion off motion There are two split pullyes made out of V-pulley. Motion from crank shaft moves the top split pulley via a worm and worm wheel. Top pulley in turn drives the bottom pulley through a belt. As the tension on the warp increases the back rest goes down and the L-type lever with weight lowers the diameter of the bottom pulley and essentially increases the diameter of the top pulley through the necessary linkages. Now the bottom pulley moves at a faster rate than it was earlier and the connecting worm to the beam drive moves more to deliver extra warp in order to reduce the warp tension.