Understanding Impression Compound in Dentistry

Impression compound is a key material in dentistry used for making negative reproductions of teeth and surrounding structures. It plays a crucial role in the fabrication of dentures, crowns, bridges, and orthodontic appliances. The accuracy of the impression directly impacts the fit and functionality of the final dental appliance. This material, introduced in 1857, is thermoplastic and comes in various forms like sheets, sticks, and cones. The properties of impression compound include high thermal expansion, shrinkage during cooling, and distortion over undercut areas. Understanding its composition and application is essential for successful dental procedures.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

SIBAR INSTITUTE OF DENTAL SCIENCES Department of Prosthodontics Related image Impression Compound Dr. Mounika, Sr.lecturer

IMPRESSION : A negative likeness or copy in reverse of the structure of an object ;an imprint of the teeth and adjacent structures for use in dentistry -GPT 9 First of many stages involved in the fabrication of dentures, crowns, inlays, bridges, orthodontic appliances, etc. Inaccuracies are minimized at this stage, and otherwise they will be carried through and possibly compounded later on.

IMPRESSION MATERIAL: Substance or combination of substances used for making an impression or negative reproduction -GPT 9 From this negative form of the teeth and surrounding structures, a positive reproduction, or cast is made. The accuracy of fit and the functional efficiency of the appliance depends upon how well the cast replicates oral tissues The accuracy of the cast depends on the accuracy of the impression in which it was cast

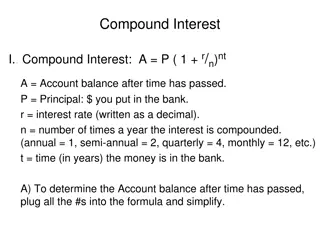

IMPRESSION COMPOUND ADA NO -3 1857, a London dentist, Charles Stent, introduced the first impression compound Oldest impression materials. Supplied in the form of sheets, sticks, cylinders and cones. Impression compound are thermoplastic materials and are softened to their working consistency by immersion in hot water or by warming over a flame.

Type I - Lower fusing materials - used for recording impression of edentulous arches Type II - Used to form a tray for the construction of dentures.

Rosin 30 Provides thermoplasticity Copal resin 30 Give quality of flow and Cohesion Carnuba wax 10 Characterizes softening temperature and produces smoothness Stearic acid Talc 5 Acts as plasticizer which improves plasticity 25 Acts as Filler, increase strength, decrease coefficient of thermal expansion Coloring agent Appropriate amount imparts colour

PROPERTIES It has a high coefficient of thermal expansion. On cooling during setting, there is considerable shrinkage. The average linear contraction of compound on cooling varies between 0.3 to 0.4 % Impression compound will distort on removal over undercut areas. Thermal conductivity of the compound is low. Due to this the outside of a mass of compound will soft whereas the inner areas will remain hard during softening. Adequate time has to be given for uniform softening

It is dimensionally instable and this is due to relaxation of stresses. Stresses are incorporated due to high coefficient of thermal expansion, poor thermal conductivity, relatively large temperature drop from mouth to room temperature To minimise distortion the safest procedure- proper cooling of impression before removal and to construct the cast immediately after removal from the mouth at least within first hour

GLASS TRANSITION TEMPERATURE - Transition of amorphous materials from a hard and relatively brittle "glassy" state into a viscous or rubbery state -39 c FUSION TEMPERATURE - The temperature at which the crystalline fatty acids solidify (43.5 c) - Above this temperature fatty acids liquify and lubricate the material to form a smooth mass - Impressions are made above this temperature

The very high viscosity characterizes muco compressive impression material. MANIPULATION The material can be softened by using a thermostatically controlled water bath at a temperature of 55 to 60 c

PRECAUTIONS - Prolonged immersion or overheating in water bath result in brittle and grainy because some of the low- molecular-weight ingredients may be leached out. - Wet kneading is suggested as water incorporates and improves the flow of material - Excessive Kneading should be avoided as it increases the flow of hardened compound and causes distortion on removal - Cast should be constructed as soon as possible to prevent from war page due to relaxation of internal stresses

APPLICATION Used to record primary impression of edentulous patients single tooth preparation using the copper ring technique Used as a check on cavity preparations in the indirect inlay procedure. Used for border extensions on impression trays. Used to form a tray for construction of dentures.

ADVANTAGES Can be used for any technique requiring a closed peripherals Can be added and readopted DISADVANTAGES They distort easily and should not be used when undercuts exist doesn't reproduced final details As it can be re used and it can't be sterilized Has high coefficient of thermal expansion of thermal expansion and low thermal conductivity Dimensionally instable

GREEN STICK COMPOUND It is a low fusing using compound Type 1 introduced by Green brothers It is similar to that of impression compound with more plasticizer it is softened by passing over flame and kneading(dry)

Uses It can be used in single tooth impression or tube impression technique Can be used as a peripheral seal material Used for border extensions of special tray

TRAY COMPOUND It is a high fusing compound it is similar to composition and working qualities of impression compound except that the temperature at which they soften i.e 70 c They resemble the shape of tray They are used to prepare custom-made preliminary impression that will later hold a secondary impression material They lack strength and dimensional stability and hence they are replaced self cure acrylic resins