Understanding Engine Cooling Systems

The cooling system in an engine is vital for maintaining optimal operating temperatures, preventing overheating, and ensuring efficient combustion. There are different types of cooling systems such as air cooling and liquid cooling, each with its advantages and disadvantages. Air-cooled engines rely on airflow to dissipate heat, while liquid-cooled engines use coolant circulation for temperature regulation. Proper cooling enhances engine performance and longevity, while overcooling can lead to decreased efficiency. Understanding the function and importance of engine cooling systems is crucial for vehicle maintenance and operation.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

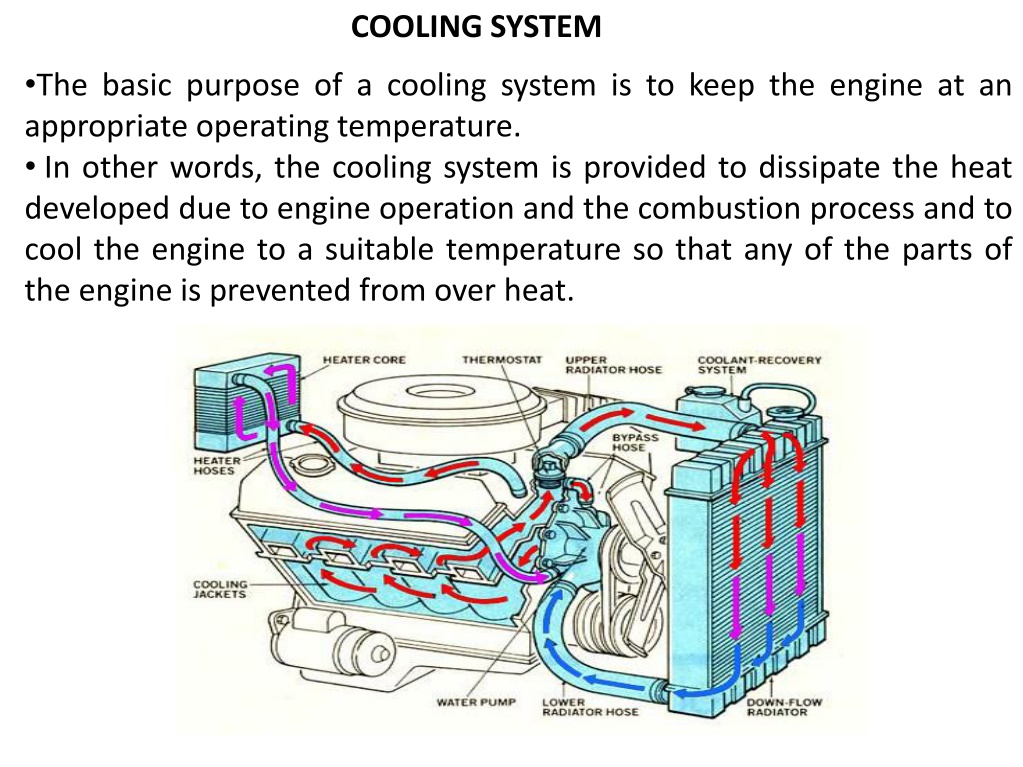

COOLING SYSTEM The basic purpose of a cooling system is to keep the engine at an appropriate operating temperature. In other words, the cooling system is provided to dissipate the heat developed due to engine operation and the combustion process and to cool the engine to a suitable temperature so that any of the parts of the engine is prevented from over heat.

Reasons for Cooling to promote a high volumetric efficiency to ensure proper combustion, and to ensure mechanical operation &reliability. Effect of Over-cooling the thermal efficiency is decreased due to more loss of heat carried by the coolant the vapourization of the fuel is less resulting in lower combustion efficiency low temperature increases the viscosity of lubricant causing more loss due to friction.

Types of Cooling System Air cooling (or direct cooling) system Liquid cooling (or indirect cooling) system Aviation engines, motor cycle and scooter engines Remark: engines cooled; automobile engines are liquid cooled. are air and while the stationery

Air coolingsystem Air cooled engines depend on airflow external surfaces of the engine necessary heat. The amount of heat dissipated depends upon: across their cylinders to remove the the area of cooling surface in contact with the air mass flow rate of air temperature difference between cylinder and air and conductivity of metal.

Cooling fins in air cooled system The area of cooling surface is increased by forming thin fins, either integrally by machining them on the outer walls of the engine cylinder and cylinder head or by attaching separate fins to them.

Air cooling system - Advantages The jackets, engine lighter. absence coolant of radiator, cooling and pumps make the The engine can be operated in cold climate where liquid may freeze. In places where water is scarce, air cooled engine is an advantage. Handling piping and pumping auxiliaries. of liquid coolant requires coolant Air leakage or freezing problems. cooled engines have no

Air cooling system - Disadvantages Relatively the cooling fan. large amount of power is used to drive Engines give low power output. Cooling and amplify the noiselevel. fins under certain conditions may vibrate Cooling is notuniform. Engines temperature. are subjected to high working

Liquid cooling systems - Types Thermosyphon system Forced circulation cooling system Evaporative cooling system

Thermo-syphon system In rotated by the crankshaft draws cold air from outside through the radiator. The radiator isconnected to the engine means of two pipes. The hot water passes through some thin pipes built in the where Thus, cooled. circulates system in the convective currents. this system, a fan Radiator Cylinder block by Piston it gets fluid the of radiator, the through form Schematic diagram of a thermosyphon system

Forced circulation cooling system This system is used in a large number of vehicles like cars, buses, trucks and other heavy vehicles. Here, circulation of water convection currents helped by a pump. takes place with The water or coolant is circulated jackets around the parts of the engine cooled, and is kept in motion by a centrifugal pump, driven from the engine. A thermostat is used to control the water temperature required for cooing. through to be Schematic diagram of a forced circulation system

Pump-cooling or forced cooling Pump is introduced between radiator and engine block Rotated by crankshaft by means of a belt Water is circulated with force => heat is removed quickly Limitation Cooling is independent of temp. =>Engine is overcooled (range of temp.=75-900C)

Parts of cooling systems: A Radiator very efficiently lower the temperature of the coolant passing through it. It consists of mainly three parts: 1) upper tank , 2) lower tank and 3) heat radiating core. The upper and lower tanks are joined by the core. The upper tank contains a neck through which coolant enters into the radiator, and over flow pipe is connected to the side. The upper and lower tanks are usually made from plastic to make lighter. The core is made from copper or brass. Radiator:

Types of Radiator: 1) According to the construction of cores: the radiators according to the construction of cores are of two types: 1) tubular type, 2)honeycomb or cellular type. 2) According to the direction of coolant flow:

Materials for radiator: Good corrosion resistance Good thermal conductivity Must possess the required strength Must be easily formable Yellow brass, copper are used Aluminium is used where weight is critical

Thermostat: 1) Bellow type thermostat: It consist of closed bellow, which is filled with a volatile liquid(like alcohol, ether or acetone). As the bellow get hot, the liquid vaporizes and the bellow expand. This sets in operation a linkage opening the valve. when the bellows are cold, they contract and the close valve this stopping the circulation of the coolant through the radiator. 2) Wax type thermostat:

Cooling fan flow across the Maintain radiator matrix. Serves the purpose when natural draft is not sufficient to cool e.g., at low speed but heavy load, when vehicle ascends uphill etc. Driven by a belt run by crankshaft. an adequate air Limitations Rising level ofnoise. Increasing consumption with engine speed. Tendency to overcool. power Cooling fan

Liquid cooling system - Advantages Because of even cooling of cylinder barrel and head (due to possible to reduce the cylinder head and valve seat temperatures. jacketing) makes it The volumetric efficiency of water cooled engines is higher than that of air- cooled engines. Compact appreciably smaller frontal area is possible. design of engines with In installation is not necessarily at the front of the mobile vehicles, cooing system can be convenientlylocated. case of water cooled engines, aircraft etc. as the

Liquid cooling system - Disadvantages Thesystem requires more maintenance. The sensitive to climatic conditions. engine performance becomes The power absorbed by the pump is considerable and output of the engine. affects the power In the event of failure of the cooling system serious damage may be caused to the engine.

Use ofAnti-freezers During winter or when the engine is kept out of operation in cold places, the cooling water in the cylinder jackets, radiator tanks and leading pipes will freeze, expand and lead to their fracture. To prevent damage to the engine and radiator during winter weather, suitable liquids or compound substances (known as anti-freezers) which go into solution are added to the water to lower the freezing temperature of the coolant. Ethylene glycol is the most widely used automotive cooling-system although methanol, ethanol, isopropyl alcohol, and propylene glycol are also used. antifreeze,

Requirements of anti- freezers They should thoroughly mix with water. They should not corrode the surfa ces with which they are in conta ct. Their boiling point should be high so that the lossdue to evaporation is minimum. They should not deposit any foreign matter in the jackets, hose, pipes or radiator. It should be chemically stable, a good conductor of heat, and a poor conductor of electricity.

Conclusions A cooling system must be provided not to the vital parts of the engine (due to high temperature), but the temperature of these components must certain limits in order to obtain maximum performance from the engine. To keep the cylinders from surrounded with a water jacket on liquid cooled engines, or with a finned surface in air cooled engines. Most small and medium sized engines used in two-wheelers, automobiles, aircraft are air cooled, while the stationery and some cooled. only to prevent damage be maintained within overheating, they are automobile engines are liquid

Conclusions A typical automotive cooling system comprises: a series of channels cast into the engine block and cylinder head, surrounding the combustion chambers with circulating water or other coolant to carry away excessive heat a radiator consisting of many small tubes equipped honeycomb of fins to radiate heat rapidly, that receives and cools hot liquid from the engine with a a centrifugal-type water pump to circulate coolant a thermostat that maintains constant temperature by automatic ally varying the amount of coolant passing into the radiator, and a fan, which draws freshair through the radiator.