Director's Review - Mechanics & Cooling Overview

The US will design and build the central portion of the Phase 2 Tracker Barrel Pixel Strip Detector (TBPS), focusing on mechanics and cooling. The project involves three layers of PS modules with specific lengths, utilizing carbon fiber/carbon foam sandwich planks with embedded CO2 cooling. Collaboration with FNAL and CERN is ongoing to address mechanical and services integration challenges. Key features include synergies with FPIX Phase 1 upgrade, experience with CO2 cooling, and leveraging past work for module support design. New challenges include integrating power supplies and optical transceivers. Progress has been made on thermal prototype planks and FEAs.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

B02 - 4 [OT - Mechanics & Cooling] 402.02.04.05 Stefan Gruenendahl February 2, 2016 S.Gr nendahl, 2016 February 2 Director's Review -- OT: Mechanics & Cooling

Outline Overview Key Features & Technical Challenges Initial Design & Prototype Work Summary Director's Review -- OT: Mechanics & Cooling S.Gr nendahl, 2016 February 2

Overview The US will design and build the central (non-tilted) portion of the Phase 2 TBPS, consisting of three layers of PS modules, with lengths around 300mm (L1) to 650mm (L3). Phase 1 FPIX experience & initial estimates indicate that mechanical support and thermal management are solvable problems. We are investigating a carbon fiber/carbon foam sandwich plank with embedded CO2 cooling. Initial designs for the module mechanical & cooling support planks, the plank support rings and cooling line interfacing exist. Engineering and technical support at FNAL has been identified. We are collaborating closely with CERN engineering for overall mechanical and services integration. The first round of thermal + gravitational distortion FEAs have been done, and results have been used to design the next thermal prototype plank, which is currently under construction. Director's Review -- OT: Mechanics & Cooling S.Gr nendahl, 2016 February 2

Phase 2 Tracker Barrel Pixel Strip Detector (TBPS) Quarter view of the TBPS US contribution: Modules Complete central part of TBPS detector Director's Review -- OT: Mechanics & Cooling S.Gr nendahl, 2016 February 2

Key Features of Mechanics & Cooling Synergies with FPIX Phase 1 upgrade Project group overlap, experience with CO2 cooling Existing test system Experience with mechanical and thermal design and FEA modeling (PS module thermal mounting same as FPIX) allows estimation/extrapolation of basic CO2 cooling parameters (power density, total power per cooling loop, flow requirements) Material for the initial prototyping (carbon fiber, stainless tubing, some carbon foam) is at hand Plank design for module support & cooling and thermal prototyping take advantage of the work done during the past 3 years for the Phase 2 Long Barrel rod design & prototyping New challenges Power supplies and optical transceivers integrated into module TBPS layer structure closely couples flat barrel and tilted barrel Director's Review -- OT: Mechanics & Cooling S.Gr nendahl, 2016 February 2

Module Support Structure (the Plank) Plank Assembly with Modules Module & module interface design from CERN Director's Review -- OT: Mechanics & Cooling S.Gr nendahl, 2016 February 2

Integration & Plank Support Planks supported by rings; services routed in Z along ring support rods; the ring support rods also provide the mechanical integration with the tilted barrel sections. Director's Review -- OT: Mechanics & Cooling S.Gr nendahl, 2016 February 2

Central Barrel Layer 1 of Central Flat PS Barrel Assembly F10049832 Director's Review -- OT: Mechanics & Cooling S.Gr nendahl, 2016 February 2

Plank Design Details M2 inserts embedded (glued with CF facing on end faces) Layer 1 Plank Assembly F10047557 3 modules on top 4 modules on bottom 320mm(L) x 136mm(W) x 6.36mm(T) Director's Review -- OT: Mechanics & Cooling S.Gr nendahl, 2016 February 2

Plank Design: Assembly View Inner & Outer tubing assemblies offset 6 mm in Z Removable Couplings Aluminum M2 Socket Head Screws 0.18mm thick (3-ply) CF facing SS Tubing OD 2.4mm 6mm thick C foam CF C support channels Titanium M2 inserts embedded (glued with cf facing on end faces) Director's Review -- OT: Mechanics & Cooling S.Gr nendahl, 2016 February 2

Removable Coupling for Tubing OD 2.413 mm CO2 Coupler Design Aluminum gasket Male Nut with 5 mm Hex; screw thread UNF #8-36 Gland Removable Coupling for Stainless Tubing 2.413 mm OD Mass in g Gland Gasket Female Nut Male Nut Hex 6.35mm 0.08 0.007 1.536 1.481 Hex 5.0 mm 0.08 0.007 0.705 1.162 Female Nut with 5 mm Hex; screw thread #8-36 Thread engagement Total, g X36 Total, g 3.104 111.744 1.954 70.344 Note: Tubing at ends not shown Director's Review -- OT: Mechanics & Cooling S.Gr nendahl, 2016 February 2

Support Ring Design End Ring Assembly F10052060 3 types of inserts embedded Foam, 3/8 thick G10 or aluminum inserts, 3/8 thick CF facing, 0.5mm thick Director's Review -- OT: Mechanics & Cooling S.Gr nendahl, 2016 February 2

First Thermal Prototype Dummy module equipped with heaters and RTDs on plank prototype Two groups of ten RTDs across pixel sensor (through openings in plank and base plate) and strip sensor Plank has stainless tubing directly imbedded with TC 5022 thermal paste into grooves in carbon foam (no sealing) Pixel side temperature sensors Director's Review -- OT: Mechanics & Cooling S.Gr nendahl, 2016 February 2

Results from First Thermal Prototype Instrumented dummy PS module mounted on CO2 cooled plank prototype Results: module itself is thermally well behaved (small T pixel-strip); plank has insufficient coupling from carbon foam to stainless tubing (FEA needs 50% air bubbles at interface to reproduce T) EXP FEA Director's Review -- OT: Mechanics & Cooling S.Gr nendahl, 2016 February 2

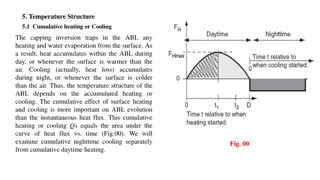

Thermal FEA & Prototyping Carbon fiber/Rohacell sandwich with carbon foam inserts around stainless steel cooling pipes (Rohacell/Airex does not save much mass compared to all carbon foam simplify structure by using all carbon foam as spacer) Also modeled graphite, TPG (block) and PGS (thin sheet) inserts around tubing only slightly better thermally, but more complicated to build Director's Review -- OT: Mechanics & Cooling S.Gr nendahl, 2016 February 2

L1 Plank Prototype ~275mm length, 6mm thick carbon foam spacer with embedded 2.2mm stainless steel cooling tubes, 3-ply ultra high modulus carbon fiber sheets at top and bottom Accommodates 3+2 PS modules To be instrumented with one or more thermal dummy modules (coupled with phase change film), and simple heaters for the remaining module positions Director's Review -- OT: Mechanics & Cooling S.Gr nendahl, 2016 February 2

L1 Plank Prototype Tubing grooves filled with boron nitride loaded epoxy, re- machined to get smooth non-porous surface Stainless tubing embedded with thermal paste (a la FPIX) Director's Review -- OT: Mechanics & Cooling S.Gr nendahl, 2016 February 2

Summary Director's Review -- OT: Mechanics & Cooling S.Gr nendahl, 2016 February 2

Summary The US is designing and building the Phase 2 Outer Tracker TBPS Central Section. FPIX experience and FEA modeling indicate that a design that meets mechanical and thermal requirements is possible. Tight integration with the titled barrel sections and close collaboration with CERN engineering is a key feature. We have a first iteration of a design for the plank itself, the plank support rings, and the cooling line interface. We are building the second thermal prototype. Director's Review -- OT: Mechanics & Cooling S.Gr nendahl, 2016 February 2