Optimization of Order Size for a Small Manufacturing Firm

A small manufacturing firm purchasing 3400 pounds of chemical dye per year seeks to minimize total costs by optimizing order sizes. With initial conditions and pricing details provided, calculations for order sizes at different price points are considered to determine the most cost-effective solutions. By analyzing ordering costs, inventory carrying costs, and supplier discounts, the firm aims to enhance operational efficiency and reduce expenses.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

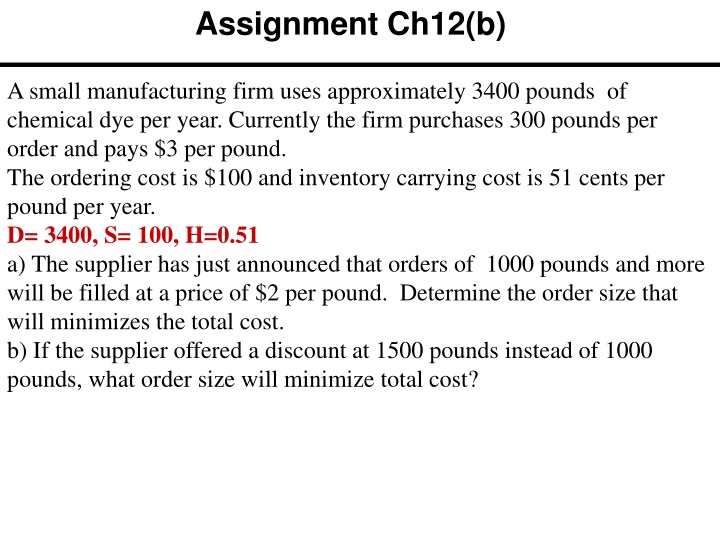

Assignment Ch12(b) A small manufacturing firm uses approximately 3400 pounds of chemical dye per year. Currently the firm purchases 300 pounds per order and pays $3 per pound. The ordering cost is $100 and inventory carrying cost is 51 cents per pound per year. D= 3400, S= 100, H=0.51 a) The supplier has just announced that orders of 1000 pounds and more will be filled at a price of $2 per pound. Determine the order size that will minimizes the total cost. b) If the supplier offered a discount at 1500 pounds instead of 1000 pounds, what order size will minimize total cost?

Ordering and Carrying Costs The Total-Cost Curve is U-Shaped Q 2 D = + TC H S Annual Cost Q Ordering Costs Order Quantity (Q) QO (optimal order quantity)

Ordering, Carrying, and Purchasing Costs Cost Adding Purchasing cost doesn t change EOQ TC with PD TC without PD PD 0 Quantity EOQ

Price Discount Cost p1 p2 0 Quantity

Total Cost Including Purchasing Cost Cost p1 p2 0 Quantity EOQ

Price Breaks: EOQ Preferred Cost 0 Quantity EOQ

Price Breaks: Discount Point Preferred Cost 0 Quantity Q

Price Breaks: EOQ Preferred Cost 0 Quantity EOQ

The Problem: Part A A small manufacturing firm uses approximately 3400 pounds of chemical dye per year. Currently the firm purchases 300 pounds per order and pays $3 per pound. The ordering cost is $100 and inventory carrying cost is 51 cents per unit per year. D=3400, S= 100, H=.51 a) The supplier has just announced that orders of 1000 pounds and more will be filled at a price of $2 per pound. 2 ( 2 100 3400 )( ) SD = = = 1155 EOQ Q P 0-999 3 1000 2 51 . H DONE

The Problem: Part B A small manufacturing firm uses approximately 3400 pounds of chemical dye per year. Currently the firm purchases 300 pounds per order and pays $3 per pound. The ordering cost is $100 and inventory carrying cost is 51 cents per unit per year. D=3400, S= 100, H=.51 b) Determine the order size that will minimizes the total cost. If the supplier offered a discount at 1500 pounds instead of 1000 pounds, what order size will minimize total cost? = 1155 EOQ Q P 0-... 3 1500 2

The Problem: Part B b) If the supplier offered a discount at 1500 pounds instead of 1000 pounds, what order size will minimize total cost? Q P 0-... 3 1500 2 D= 3400, S=100, H= .51 = 1155 EOQ TC = HQ/2 + SD/Q + PD TC ( Q = 1155 , P = 3) = 0.51(1155)/2 + 100(3400)/1155 + 3(3400) TC = 294.5 + 294.5 + 10200 = 10789 TC ( Q = 1500 , P = 2) = 0.51(1500)/2 + 100(3400)/1500 + 2(3400) TC = 382.5+226.7 +6800 = 7409.2