Occupational Health & Safety: The 4M Method in Construction Sites

The 4M method in occupational health and safety involves analyzing and addressing workplace hazards through four key elements: Manpower, Machinery, Materials, and Method. In a construction site scenario, safety measures include regular training for workers on machinery usage, maintenance of equipment, proper handling of materials, and adherence to safety protocols for work methods. Utilizing state-of-the-art machinery, safety-conscious practices, and effective management strategies are crucial components of ensuring a safe construction environment.

Uploaded on Apr 02, 2024 | 4 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

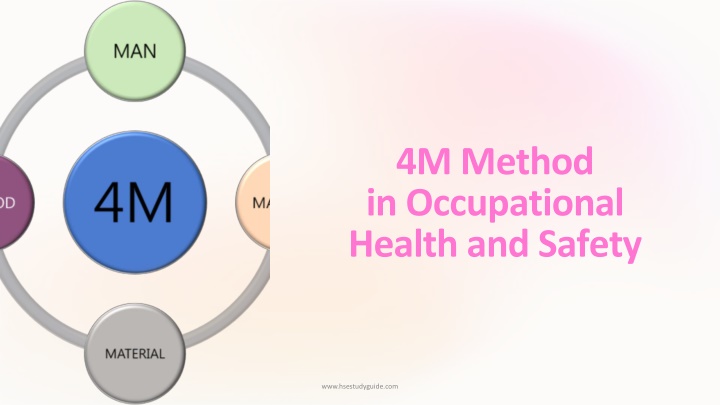

4M Method in Occupational Health and Safety www.hsestudyguide.com

4M Method The 4M method in occupational health and safety refers to a systematic approach used to analyze and address workplace hazards. It involves considering four key elements that contribute to safety: www.hsestudyguide.com

4M Method four key elements Manpower: Machinery: This aspect focuses on the human factor in the workplace, including employees' skills, training, and behavior. It involves ensuring that workers are adequately trained, competent, and aware of safety procedures to prevent accidents. Machinery encompasses all equipment, tools, and technology used in the workplace. It involves evaluating the safety features of machinery, conducting regular maintenance, and implementing safeguards to prevent accidents related to equipment malfunction or misuse. www.hsestudyguide.com

4M Method four key elements Materials: Method: This element involves the substances, chemicals, or materials used in the workplace. Ensuring the proper handling, storage, and disposal of hazardous materials is crucial to prevent exposure and accidents that may harm employees' health. Method refers to the processes, procedures, and work methods employed in the workplace. It involves assessing work procedures to identify potential hazards, implementing safety protocols, and continuously improving methods to minimize risks. www.hsestudyguide.com

Scenario: Construction Site Safety using the 4M Method Manpower: Machinery: At a construction site, the safety manager conducts regular training sessions for all workers on proper handling of heavy machinery and equipment. They ensure that each worker is certified and trained in their respective tasks, such as operating cranes or using power tools. Additionally, toolbox talks are held every morning to reinforce safety protocols and promote a safety-conscious work culture among the workforce. The construction company invests in state-of-the-art machinery equipped with the latest safety features. Regular maintenance schedules are strictly followed to ensure that all equipment is in optimal working condition. Safety sensors and alarms are installed on heavy machinery to alert operators of any malfunctions or potential hazards, minimizing the risk of accidents. www.hsestudyguide.com

Scenario: Construction Site Safety using the 4M Method Materials: Method: The site manager conducts thorough inspections of all materials delivered to the construction site, ensuring they comply with safety standards and are properly labeled. Hazardous materials are stored in designated areas away from other construction materials, and clear signage is posted to indicate the nature of the stored materials. Workers handling hazardous substances are provided with appropriate personal protective equipment (PPE) and trained on safe handling and disposal procedures. Before starting any construction activity, a detailed risk assessment is carried out to identify potential hazards. Site- specific safety plans are developed, outlining step-by-step procedures for each task. Daily safety checks are conducted, and any deviations from the safety protocols are immediately addressed. Regular safety audits are also performed to assess the effectiveness of the safety measures in place and make necessary improvements. www.hsestudyguide.com

Conclusion By addressing these four elements comprehensively, the 4M method helps organizations identify potential hazards, mitigate risks, and promote a safer work environment for employees. www.hsestudyguide.com