Magnet Lifting Requirements and Model Description for MQXFA Prototype

Descriptions and considerations for lifting and handling a heavy magnet in a prototype project, including safety requirements, coil strain limits, and the use of an existing lifting structure. Details on the lifting process, equipment, and structural modeling using ANSYS Workbench are provided.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

MQXFA Magnet Lifting Heng Pan, Dan Cheng 03-16-2017

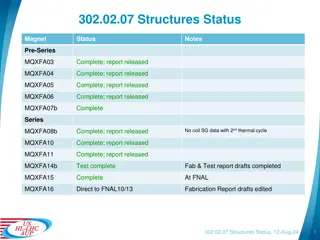

MQXFA Handling Requirements LARP Short model MQXFS1/2 LARP Short model MQXFS4 LARP 1st prototype MQXFA1 LARP Prototype MQXFA2 and 3 Coil X-section design v1 v2 v2 v2 Coil Magnetic length RT/1.9 K (mm) 1198/1194.4 1200/1196.4 4000/3988 4212.6/4200 Coil Physical length RT (mm) 1510 1510 4312 4522.6 Structure (yoke) length RT (mm) 1550 1550 4563 4563 MQXFA magnet handling includes the work of lifting the horizontal magnet with slings and pivoting the magnet in a shipping fixture; this talk covers only the horizontal lifting operations. See BNL s talk for the discussion of the pivoting operation. The magnet weighs ~15,000 lbs. The lifting and handling operations for this magnet have to meet: (A). Safety requirements---loading capacity of the spread bar (B). Coil strain limit---less than 0.05% (C). Avoid separation in yoke stacks 9/20/2024 H. Pan, Dan Cheng 2

Background Discussions 12/13/2016 https://indico.fnal.gov/conferenceDisplay.py?confId=13432 1/25/2017 https://indico.fnal.gov/conferenceDisplay.py?confId=13715 2/03/2017 https://indico.fnal.gov/conferenceDisplay.py?confId=13761 3/03/2017 https://indico.fnal.gov/conferenceDisplay.py?confId=13935 For Lifting we settled on: Using existing LBNL spreader bar and four matched straps + load cells and turnbuckles to even the loads. BNL shipping fixture will also be used for rotating magnet vertical 9/20/2024 H. Pan, Dan Cheng 3

LBNL Lifting structure Existing 60,000 lb. capacity lifting spreader bar Meets requirement (A) Four-strap lifting case will incorporate the use of 4 load cells 4 matched slings 4 turnbuckles (for adjustability and levelling) 9/20/2024 H. Pan, Dan Cheng 4

Model description Half size model in ANSYS Workbench. Contact Assumption Pole and coils Bonded 3 ft Coil mid-planes No-separation (slide allowed) 5.9 ft Coil and fillers No-separation (slide allowed) 3 ft Collar and polekey No-separation (slide allowed) Collar and fillers Bonded Collar and pad No-separation (slide allowed) Y-Z Symmetry plane Pad and masters No-separation (slide allowed) Yoke and masters No-separation (slide allowed) Fixed support boundary condition applied on the inner surface of the lifting hole. Yoke and shells No-separation (slide allowed) Shell segments Frictional, 0.2 friction coefficient Masters and load keys Bonded Shell and slings No-separation (slide allowed) The lamination stacks and coils are simplified as homogeneous blocks. Coil is linear isotropic with elastic modulus of 20 GPa and = 0.3. All slings are uniform in length. Neglect the axial loading of coils. 9/20/2024 H. Pan 5

Worst case: 2-Point support on ends Two supports at the ends Total deformation of ~500 m on the magnet This is the worst case of lifting: Only two supports on the ends 1 g vertical load The coil strain is less than the 0.05% criteria (see appendix slide I). The yoke rods force could allow tension of ~3.6 MPa beforeseparation (this is exceeded) Axial stress on yoke stacks on the mid-plane of the magnet 9/20/2024 H. Pan, Dan Cheng 6

MQXFA Magnet 4-Sling Lifting Case The worst case shows that concern over coil strain is not the limiting factor rather, separation of the yokes must be prevented Four-sling lifting case requires the consideration of the deflections of the spreader bar Measuring the reaction forces on each sling requires load cells on each, as well as the ability to adjust lengths LBNL riggers have a set of digital wireless load cells May purchase a dedicated set for MQXFA (reduces schedule risk) High capacity chainfalls may not fit in space allotted, or require too long of length; exploring turnbuckles instead 9/20/2024 H. Pan, Dan Cheng 7

1g load System result including the spreader bar, slings and magnet The result shown below is the case of 1g vertical load, sling with 20 GPa modulus; Coil strain in this case is less than the criteria; No separation of yoke lamination (Max. axial stress on yoke is 1.7 MPa < 3.6 MPa) 9/20/2024 H. Pan, Dan Cheng 8

1g load contd Part result: Total deformation of 60 m on the magnet Magnet deflection Spreader bar deflection 9/20/2024 H. Pan, Dan Cheng 9

2g load System result including the spreader bar, slings and magnet The result shown below is the case of 2g vertical load, sling with 20 GPa modulus; Coil strain in this case is less than the criteria; No separation of yoke lamination (Max. axial stress on yoke is 2.7 MPa < 3.6 MPa) 9/20/2024 H. Pan, Dan Cheng 10

2g load contd Part result: Total deformation of 110 m on the magnet Magnet deflection Spread bar deflection 9/20/2024 H. Pan, Dan Cheng 11

1g Results with 10 GPa sling modulus Sling: 10 GPa Total deformation of 70 m on the magnet Coil strain in this case is less than the criteria; No separation of yoke lamination (Max. axial stress on yoke is 1.8 MPa < 3.6 MPa) 9/20/2024 H. Pan, Dan Cheng 12

1g Results with 50 GPa sling modulus Sling: 50 GPa Total deformation of 28 m on the magnet Coil strain in this case is less than the criteria; No separation of yoke lamination (Max. axial stress on yoke is 0.9 MPa < 3.6 MPa) 9/20/2024 H. Pan, Dan Cheng 13

Results summary with different sling moduli 1. From the beam theory, more load on the center supports will reduce the beam deflection until it s fully supported: insufficient supporting full supporting over supporting 2. The center slings will carry more load than the outboard ones in a passive lifting: Sling material Load on center slings (lb) Center sling contribution Max. magnet deformation ( m) (1g load) 10 GPa 8000 53.5% 70 20 GPa 8460 54.7% 60 50 GPa 8766 58.4% 28 3. The deformation of the magnet in passive lifting (all slings are initially uniform in length) is acceptable. With load cells and turn buckles we can actively tune the lift points to better support the magnet 9/20/2024 H. Pan, Dan Cheng 14

Lifting with the shipping fixture Support points Contact Assumption Support points Channel and clamps Bonded Clamps and magnet No-separation (slide allowed) Al cradles and clamps Hoist block Steel channels Half size model in ANSYS Workbench Contact setting inside magnet is same as the lifting cases. Fixed supports are applied on the hoist blocks. 9/20/2024 H. Pan, Dan Cheng 15

1 g horizontal lifting Overall deflection is 64 m Magnet deflection is 49 m Max. coil strain is 6 m/m No separation in yoke stacks (Max. axial stress on yoke is 1.6 MPa < 3.6 MPa) 9/20/2024 H. Pan, Dan Cheng 16

1.5 g horizontal lifting Magnet deflection is 96.2 m Magnet deflection is 73.6 m Max. coil strain is 9 m/m No separation in yoke stacks (Max. axial stress on yoke is 1.7 MPa < 3.6 MPa) 9/20/2024 H. Pan, Dan Cheng 17

Summary The magnet deformation and coil strains with a passive four-sling configuration are acceptable The coil strain on all cases is below the criteria No separation of the yokes occurs The magnet deformation will be reduced further with active tuning with the turnbuckles This tuning can lift the magnet in a more neutral state The magnet deformation and coil strains when lifting the magnet in the BNL shipping fixture are acceptable. Research and procurement of the matched lift rigging is in process 9/20/2024 H. Pan, Dan Cheng 18

Appendix I Coil strain in the worst case (two end supports): Max. coil strain is about 22.4 m/m, which is less than the criteria. 9/20/2024 H. Pan, Dan Cheng 19

Appendix II Correlation of magnet deflection and coil strain The correlation is derived from the horizontal lifting cases with four slings; Coil strain concentrates around the lifting positions. 140 Max. Coil Equivalent Strain ( ) 120 The coil strain will not limit the magnet handling. 100 80 60 40 20 0 0 50 100 150 200 250 Max. Magnet Deflection ( m) 9/20/2024 H. Pan, Dan Cheng 20