Macromechanical Analysis of Lamina Failure Theory

The failure theories in macromechanical analysis are based on the normal and shear strengths of a unidirectional lamina, with five strength parameters. A lamina is considered failed if certain criteria related to ultimate strain values are violated. In a specific example with a Graphite/Epoxy lamina, off-axis loading leads to stresses in local axes, and a linear relationship is assumed between stresses and strains.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Chapter 2 MacromechanicalAnalysis of a Lamina Maximum Strain Failure Theory Dr. Autar Kaw Department of Mechanical Engineering University of South Florida, Tampa, FL 33620 Courtesy of the Textbook Mechanics of Composite Materials by Kaw

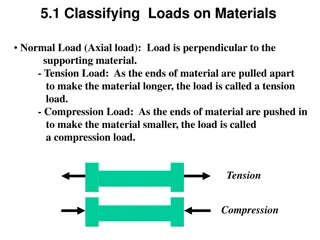

The failure theories are generally based on the normal and shear strengths of a unidirectional lamina. In the case of a unidirectional lamina, the five strength parameters are: ( )ult 1 T Longitudinal tensile strength ( )ult 1 C Longitudinal compressive strength ( )ult 2 T Transverse tensile strength ( )ult 2 C Transverse compressive strength ( )ult In-plane shear strength 12

The lamina is considered to be failed if: ( ) ( ) ( ( ) , or < ult 1 ( ) , or < ult 2 ( 12 12 < C 1 T < 1 ult C 2 T < 2 ult ) ) , ult < 12 ult is violated, where: ( )ult 1 ( )ult 1 ( )ult 2 ( )ult 2 ( )ult 12 T = Ultimate longitudinal tensile strain (in direction 1), C = Ultimate longitudinal compressive strain (in direction 1), T = Ultimate transverse tensile strain (in direction 2), = Ultimate transverse compressive strain (in direction 2), C = Ultimate in-plane shear strain (in plane 1-2).

= = = 2 , 3 , and 4 S S S Find the maximum value of S>0 if a stress of is applied to a 60o lamina of Graphite/Epoxy. Use Maximum Strain Failure Theory. Use properties of a unidirectional Graphite/Epoxy lamina given in Table 2.1 of the textbook Mechanics of Composite Materials by Autar Kaw. x y xy FIGURE 2.33 Off-axis loading in the x-direction

The stresses in the local axes are: 0 2500 0 7500 0 8660 2 . . . S 1 0 7500 0 2500 0 8660 3 = . . - . - S 2 0 4330 0 4330 0 5000 4 - . . - . S 12 1 . 1714 0 10 1 0 2714 = - . S. 10 1 0 4165 - . 10

The strains in the local axes are: 1 1 S = 2 2 12 12 10 . 1367 0 10 0 11 11 1 0 5525 . 1547 0 . 1714 0 . 10 10 10 = 9 0 2662 . S. 0 11 10 1 - . 1547 0 0 9709 0 2714 = . . S 10 10 10 10 0 0 - 9 1 . 1395 0 0 4165 . 10 10 9 0 5809 . 10

Assume there is a linear relationship between all the stresses and strains till failure, then the ultimate failure strains are: T 1 ( ) 6 1500 10 3 T 1 - ( 8 287 ult = = = . , ) 10 ult 9 181 10 E 1 C 1 ( ) 6 1500 10 3 C 1 ( 8 287 ult = = = . , ) 10 ult 9 181 10 E 1 T 2 ( ) 6 40 10 3 T 2 ( 3 883 ult = = = . , ) 10 ult 9 10 3 . 10 E 2 C 2 ( ) 6 246 10 2 C 2 ( = ) 2 388 ult = = . , 10 9 10 3 . 10 E ( 2 ) 6 68 10 12 3 ( ) 9 483 ult = = = . . 10 ult 12 9 7 . 17 10 G 12

10 . 1367 0 10 3 10 3 8 287 . 1367 0 8 287 . < S< . , 10 10 10 1 9 0 2662 = 12 . S 10 2 2 9 3 2 388 0 2662 3 883 . < . S< . , 10 10 10 - 9 0 5809 . 10 3 9 3 9 483 0 5809 9 483 . < . S< . , 10 10 10 3 T - 8 287 . ( = ult ) 10 1 or: 3 C 8 287 . ( = ) 10 1 ult 6 6 606 2 606 2 . <S< . , 10 10 3 T 3 883 . 6 6 ( = 14 58 . 89 71 . ) <S< 10 10 10 2 ult 6 6 16 33 16 33 . <S< . , 10 10 2 C 2 388 . ( = ) 10 2 ult which give: 3 9 483 . ( = ) 10 <S< 0 16 MPa. 33 . 12 ult

The strength ratio from Maximum Stress Failure Theory and Maximum Strain Failure Theory is 16.33 MPa. There is no difference between the two values because the mode of failure is shear. However, if the mode of failure were other than shear, there would have been a difference between the strength ratios due to the Poisson's ratio effect, which couples the normal strains and stresses in the local axes. Neither, the Maximum Stress Failure Theory nor the Maximum Strain Failure Theory have any coupling between the three possible modes of failure.