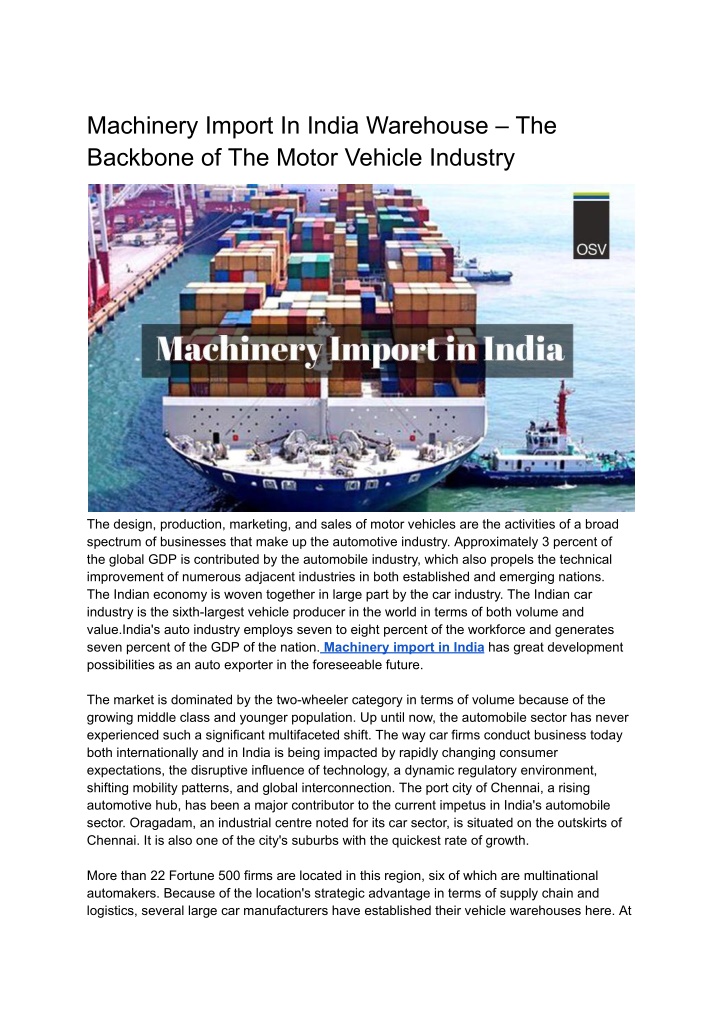

Machinery Import In India Warehouse – The Backbone of The Motor Vehicle Industry

The design, production, marketing, and sales of motor vehicles are the activities of a broadnspectrum of businesses that make up the automotive industry. Approximately 3 percent ofnthe global GDP is contributed by the automobile industry, which also propels the technicalnimprovement of numerous adjacent industries in both established and emerging nations.nThe Indian economy is woven together in large part by the car industry. The Indian carnindustry is the sixth-largest vehicle producer in the world in terms of both volume andnvalue.India's auto industry employs seven to eight percent of the w

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Machinery Import In India Warehouse The Backbone of The Motor Vehicle Industry The design, production, marketing, and sales of motor vehicles are the activities of a broad spectrum of businesses that make up the automotive industry. Approximately 3 percent of the global GDP is contributed by the automobile industry, which also propels the technical improvement of numerous adjacent industries in both established and emerging nations. The Indian economy is woven together in large part by the car industry. The Indian car industry is the sixth-largest vehicle producer in the world in terms of both volume and value.India's auto industry employs seven to eight percent of the workforce and generates seven percent of the GDP of the nation. Machinery import in India has great development possibilities as an auto exporter in the foreseeable future. The market is dominated by the two-wheeler category in terms of volume because of the growing middle class and younger population. Up until now, the automobile sector has never experienced such a significant multifaceted shift. The way car firms conduct business today both internationally and in India is being impacted by rapidly changing consumer expectations, the disruptive influence of technology, a dynamic regulatory environment, shifting mobility patterns, and global interconnection. The port city of Chennai, a rising automotive hub, has been a major contributor to the current impetus in India's automobile sector. Oragadam, an industrial centre noted for its car sector, is situated on the outskirts of Chennai. It is also one of the city's suburbs with the quickest rate of growth. More than 22 Fortune 500 firms are located in this region, six of which are multinational automakers. Because of the location's strategic advantage in terms of supply chain and logistics, several large car manufacturers have established their vehicle warehouses here. At

this area, businesses such as Apollo Tyres, Daimler AG, Renault-Nissan, Komatsu, Ford, BMW, Mitsubishi, and Toyota are present. They have warehouses where they store their finished goods, raw materials, and replacement parts that are ready to be sent. The Automobile warehouse layout Since the car industry depends heavily on OEM supply, having a functional layout aids in efficiency development. For the most part, we think of the auto industry as one big assembly line producing cars. Given the numerous components from infotainment systems to steering wheels it is, nonetheless, more intricate than that. It becomes vital to make sure the supply chain is kept up in a way that reduces mistakes and boosts efficiency. For instance, getting the most out of your drivers, tractors, and equipment would be facilitated if your suppliers are close to your warehouse. By keeping the final site of storing components close to the destination, you may also save lead times and maintain low inventory levels. Because it directly affects the production and efficiency of your warehouse for Machinery import in India, an efficient warehouse plan is crucial. Keeping a standard and error-proofing to guarantee that the correct item arrives at the right place at the right time each and every time. To create a simplified operation, increase productivity, and cut costs, the layout should place the steps in a logical order. The product range of the firm, the quantity of goods in a product line, and the size of the products should all be taken into consideration while designing the warehouse plan. Setting up the warehouse and allocating resources requires careful consideration of these factors. U Flow optimisation for Machinery import in India is one of the most often used options for warehouse layout design. This feature consists of receiving docks on one side of the structure, and a U-shaped packing room, dynamic and static shelves, and unloading area through the building. The distribution docks and shipment staging facility mark the completion of the U. A bottleneck in the flow does not impede the passage of merchandise or equipment along two separate channels. In addition to reducing product handling, this arrangement provides excellent cross-docking capacity. Few simple points to focus on to improve the automobile warehouse design Information gathering and analysis: For information to be arranged in a warehouse, it has to be current, correct, and easily accessible. A lot of these choices, such using barcodes and supporting gear and software, are now incorporated in warehouse management systems (WMS) as a way to automate data collecting. Infrastructure for employee health and safety: Work in warehouses comes with threats to one's health and safety. Should you fail to manage them, your warehouse can have a high rate of employee turnover, workers who perform below expectations, sicknesses and injuries that prevent them from showing up for work, legal problems, and eventually, deaths. Generally speaking, whether your employees drive lift trucks or forklifts, forklift safety is critical to minimising crush and impact accidents.

Workplace ergonomics: By using ergonomics in a neutral posture, employees may use them without reaching above or below their bodies. For example, certain goods in every warehouse move more quickly than others because of their huge volume. According to the 80/20 Rule, you will choose 80 percent of the goods you offer 80 percent of the time. You may focus on your most significant goods in this way to get the greatest ergonomic outcomes. Robotics: Manufacturers of automobiles and automotive components may employ robots to boost output, cut expenses, enhance quality, and safeguard workers. Automakers now have more alternatives thanks to collaborative robotics, or "cobots," including the ability to place robots in close proximity to human personnel without the need for fences. Types of material handling equipment in automobile warehouse In general, material handling equipment for Machinery import in India may be divided into many broad categories. Transport equipment is used to transfer materials from one location to another. It is meant to move, regulate, protect, or store items via numerous operations at warehouses and facilities. A few examples would be industrial trucks, cranes, and conveyors. Equipment for unit load creation is used to limit material movement and preserve material integrity. Pallets, skids, slip sheets, bins, baskets, cartons, bags, and crates are a few types of unit load forming equipment. Storage equipment is used to reflect trade-offs between maximising space efficiency (cube utilisation), minimising handling expenses, and enhancing material accessibility in warehouse architecture. When materials can be loaded, unloaded, rotated, and fed into a specific spot at work so they may be handled, crafted, transported, or stored, that equipment is known as positioning equipment. Identification and Management for Machinery import in India In order to manage the movement of materials within a facility as well as between a facility and its suppliers and consumers, equipment is utilised under a system for gathering, storing, and exchanging information. The identification of materials and the execution of related controls don't require any specialised equipment.

Why the automobile industry needs warehouse automation As companies strive to fulfil the need for fulfilment, warehouse automation is at its pinnacle. One benefit of robotic process automation is that it allows for the transition from physical robots to digital bots, with bots answering client inquiries. There are several approaches to automate warehouses, such as using robots and machinery to automate worker participation in inventory procedures from the time items arrive until they leave. This approach can lower labour costs while increasing accuracy and efficiency. A warehouse management system (WMS) is software that regulates and oversees the daily activities of a warehouse. In addition to maximising order selection, packing, and shipping efficiency, the WMS helps with inventory receipt, placement, and packaging. Warehouse management may be integrated into the enterprise resource planning system (ERP) or it may be created as a stand-alone programme. Systems for managing inventory in warehouses used to provide basic features including storage location data. From straightforward pick, pack and ship features to complex programmes that manage complex interactions with material handling systems and yard management, modern WMS like Onnsynex offer a wide range of capabilities.