Machine Design Fundamentals and Calculations

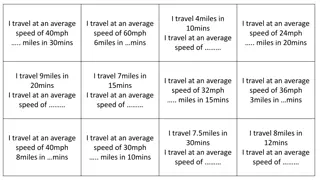

This lecture covers examples of calculating key parameters in machine design, such as finding the diameter of chain links for a crane, determining tensile stress in cast iron links, and analyzing the load distribution in steel rods supporting a hydraulic press. The solutions provided demonstrate practical applications of engineering principles.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

INTRODUCTION TO MACHINE DESIGN Lec.2 Dr. Ameer Ali Kamel Prod.Eng.& Mech. Design Dept. Faculty of Engineering

Example 1 A coil chain of a crane required to carry a maximum load of 50 kN, Find the diameter of the link stock, if the permissible tensile stress in the link material is not to exceed 75 MPa.

Given: P = 50 kN = 50 103N ; = 75 MPa = 75 N/mm2 Let: d = Diameter of the link stock in mm. Area = d2/4 = 0.8754 d2 It is known that, the maximum load (P), 50 103= tA = 75 0.7854 d2= 58.9 d2 d2= 50 103 / 58.9 = 850 d = 29.13 30 mm

Example 2 A cast iron link is required to transmit a steady tensile load of 45 kN. Find the tensile stress induced in the link material at sections A-A and B-B.

Given: P = 45 kN = 45 103N Tensile stress induced at section A-A It is known that the cross-sectional area of link at section A-A, A1 = 45 20 = 900 mm2 Tensile stress induced at section A-A, 3 P 10 x 45 = = = = = = 2 N mm 50 / t 1 A 900 1

Tensile stress induced at section B-B It is known that, the cross-sectional area of link at section B-B, A2= 20 (75 40) = 700 mm2 Tensile stress induced at section B-B, 3 P 10 x 45 = = = = = = 2 N mm 2 64 3 . / A 700 1

Example 3 A hydraulic press exerts a total load of 3.5 MN. This load is carried by two steel rods, supporting the upper head of the press. If the safe stress is 85 MPa and E = 210 kN/mm2, find : 1. diameter of the rods, and 2. extension in each rod in a length of 2.5 m. Solution Given: P = 3.5 MN = 3.5 106 N t= 85 MPa = 85 N/mm2 E = 210 kN/mm2= 210 103N/mm2 l = 2.5 m = 2.5 103mm 1. Diameter of the rods Let d = Diameter of the rods in mm. Area = d2/4 = 0.8754 d2

Since the load P is carried by two rods, therefore load carried by each rod is, P1 = P/2 = 3.5 x106/2 = 1.75 106N It is known that load carried by each rod (P1), 1.75 106= t . A = 85 0.7854 d 2 = 66.76 d2 d 2= 1.75 106/66.76 = 26 213 d = 162 mm 2. Extension in each rod Let: l = Extension in each rod. It is known that Young's modulus (E), 3 P xL x x 85 5 . 2 10 = = = = = = = = 5 t E x 1 . 2 10 1 A x L L L L l = 212.5 103/(210 103) = 1.012 mm

Example 4 A rectangular base plate is fixed at each of its four corners by a 20 mm diameter bolt and nut as shown. The plate rests on washers of 22 mm internal diameter and 50 mm external diameter. which are placed between the nut and the plate are of 22 mm internal diameter and 44 mm external diameter. If the base plate carries a load of 120 kN (including self-weight, distributed on the four corners), calculate the stress on the lower washers before the nuts are tightened. What could be the stress in the upper and lower washers, when the nuts are tightened so as to produce a tension of 5 kN on each bolt? Copper washers which is equally

Solution Given : d = 20 mm d1= 22 mm d2= 50 mm d3= 22 mm d4= 44 mm P1= 120 kN P2 = 5 kN Stress on the lower washers before the nuts are tightened It is known that, the area of lower washers is: ( ( ) ) ( ( ) ) 2 d = = = = = = 2 2 1 2 2 2 A d mm ( 50 ) ( 22 ) 1583 1 4 4

and the area of the upper washer is: ( ( ) ) ( ( ) ) 4 d = = = = = = 2 2 3 2 2 2 A d mm ( 44 ) ( 22 ) 1140 1 4 4 Since the load of 120 kN on the four washers is equally distributed, therefore load on each lower washer before the nuts are tightened, P1 = 120 / 4 = 30 kN = 30 000 N The stress on the lower washers before the nuts are tightened,

P 30000 = = = = = = = = 2 1 N mm MPa 18 95 . / 18 95 . c 1 A 1583 1 Stress on the upper washers when the nuts are tightened The tension on each bolt, when the nut is tightened, is expressed as follows: P2= 5 kN = 5000 N Stress on the upper washers when the nut is tightened, P 5000 = = = = = = = = 2 2 N mm MPa . 4 38 / . 4 38 c 2 A 1140 2

Stress on the lower washers when the nuts are tightened It is also known that, the stress on the lower washers, when tightened, can be expressed as follows: the nuts are + + + + P P 30000 5000 = = = = = = = = 2 1 2 N mm MPa 22 11 . / 22 11 . c 3 A 1583 1

Example 4.5 The piston rod of a steam engine is 50 mm in diameter and 600 mm long. The diameter of the piston is 400 mm and the maximum steam pressure is 0.9 N/mm2. Find the compression of the piston rod if the Young's modulus for the material of the piston rod is 210 kN/mm2. Solution Given: d = 50 mm l = 600 mm D = 400 mm P = 0.9 N/mm2 E = 210 kN/mm2= 2.1 105N/mm2

Let: l = Compression of the piston rod. Therefore, the cross-sectional area of piston, can be expressed as follows: = = = = = = 2 2 2 A D mm ( 400 ) 125680 4 4 Maximum load acting on the piston due to steam, P = Cross-sectional area of piston Steam pressure = 125 680 0.9 = 113 110 N Also, cross-sectional area of piston rod, = = = = = = 2 2 2 A d mm ( 50 ) 1964 4 4

Also, Young's modulus (E), P xL x 113110 600 = = = = == == 5 E x 1 . 2 10 A x L L 1964 34555 = = 5= = L mm . 0 165 x 1 . 2 10

Shaft Design 3. Design Based on twisting & bending Moments Mt=127.5 N.m Mx=556.5 N.m My=619 N.m Design will be carried out according to one of the theories of elastic failure. (i.e., Maximum shear or maximum principle stress theory).