LED Bulb Cooling Simulation with COMSOL

LED bulbs are preferred for their longevity and energy efficiency, but 70% of electrical power is lost as heat. This simulation using COMSOL optimizes the design to prevent overheating by considering heat sources, heat transfer, natural convection, and boundary conditions. Results show efficient cooling mechanisms inside and outside the bulb, maintaining optimal temperature levels.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

LED Bulb Cooling COMSOL

Background Light-emitting diode (LED) bulbs are nowadays preferred to incandescent light bulbs because of their higher longevity and energy efficiency In LED bulbs, light is produced by electroluminescence, but 70% of the electrical power consumed is lost as heat in the process Geometry and material properties can be optimized during the design process to prevent the bulb from overheating

Model Definition The device consists of an aluminum PCB supporting LED chips inside a plastic bulb The inside and outside of the bulb are filled with air Symmetries are used on the two planes of symmetry to reduce computational time Model geometry

Model Definition LED chips are considered as heat sources dissipating power equal to the heat losses The radiative surface-to-ambient heat transfer is taken into account on the PCB and LED chips Buoyancy forces are taken into account for natural convection inside and outside the bulb Model boundary conditions

Model Definition Free boundaries are defined around the bulb, with a pressure constraint on the bottom boundary to close the problem Model boundary conditions

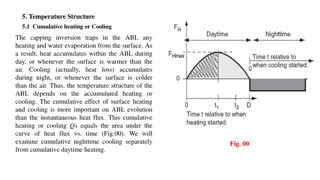

Results The LED chips are cooled by conduction and convection with the air inside the bulb, and by radiation to the ambient air The air inside the bulb is itself cooled by conduction with the plastic bulb in contact with ambient air The hot air inside the bulb can escape through small holes on the top of the bulb Temperature field outside the LED bulb

Results The thin film of hot air around the bulb creates a vertical airflow due to buoyancy forces Convective cells appear inside the bulb Velocity field inside and outside the LED bulb