How Product Traceability Software Tracks Product Batches

nThis presentation explains how product traceability software tracks product batches through data collection, batch identification, real-time monitoring, and compliance with regulations. It highlights the software's role in managing recalls, ensuring quality, and providing valuable analytics, with real-world examples of successful use cases.

Uploaded on | 2 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

How Product Traceability Software Tracks Product Batches

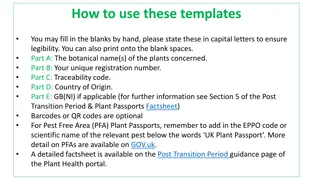

Introduction to Product Traceability Traceability Software Product traceability software plays a crucial role in modern supply chains, enabling businesses to track the movement and status of their raw materials to finished goods. This powerful tool provides real-time and helps ensure quality, compliance, and efficiency throughout the process.

Understanding Product Batches Batch Production Process Batch Identification Batch Storage and Handling Each product batch is Product batches are Proper storage and handling assigned a unique identifier, handling of product batches produced in controlled identifier, such as a lot manufacturing runs, where a batches is crucial to maintain number or production code, where a set quantity of goods maintain quality and safety. code, that is printed on goods are made together safety. Batches are typically packaging and tracking labels. under consistent conditions. typically kept together in labels. This allows the batch conditions. This ensures inventory and distributed in batch to be tracked product quality and in the order they were throughout the supply chain. traceability. produced. chain.

Tracking Product Movements Inbound Tracking Track products as they arrive at your facility, logging details like delivery date, date, supplier, and batch information. Internal Transfers Monitor the movement of products within your operation, recording when batches when batches are moved to different storage locations or production lines. lines. Outbound Shipping Capture data on when and where finished products are shipped to customers or customers or distributors, including order details and delivery confirmation. confirmation.

Capturing Batch-Level Data Batch Coding Data Capture Advanced Analytics Traceability software can The software automatically With batch-level data, apply unique batch codes to automatically records key businesses can perform in - to track products at the batch details like production date, in- depth analysis to identify batch level. This enables date, expiration date, and identify trends, optimize detailed monitoring and quality test results for every processes, and make data - reporting of each production every batch. This creates a data- driven decisions to production run. comprehensive digital audit improve product quality. audit trail.

Integrating with Supply Chain Systems Systems Traceability solutions seamlessly integrates integrates with your existing supply chain chain systems, enabling real-time tracking and tracking and visibility across your entire operations. This allows you to trace product product movements, monitor inventory levels, levels, and manage recalls efficiently. By sharing data between your traceability traceability system and other enterprise applications, you can automate workflows, workflows, streamline processes, and make make more informed business decisions based based on a holistic view of your supply chain. chain.

Enabling Recall and Withdrawal Processes Identify Affected Batches Quickly pinpoint specific product batches impacted by quality 1 by quality issues or safety concerns. Notify Customers 2 Rapidly communicate with customers to initiate a targeted recall or withdrawal. Track Returns 3 Monitor the return and destruction of affected products to ensure full compliance. compliance. Traceability solutions enables companies to execute efficient, targeted recalls and withdrawals when withdrawals when necessary. By quickly identifying the specific batches involved, the system allows system allows the organization to swiftly notify customers and track the return of affected products. affected products. This minimizes disruption, protects brand reputation, and ensures full regulatory regulatory compliance.

Improving Inventory Management Tracking Batch Movements Automated Reporting Expiration Date Management Product traceability Detailed batch-level The software can track software enables reports provide insights expiration dates and precise monitoring of insights to optimize flag batches nearing the of batch movements inventory, identify slow - end of their shelf life, through the supply slow- moving items, and allowing proactive chain, allowing real- and ensure the right inventory rotation to time visibility into products are available minimize waste. inventory levels and available when and locations. where they are needed. needed.

Ensuring Regulatory Compliance Traceability software plays a crucial role in helping organizations comply with comply with complex regulatory requirements. It provides a comprehensive comprehensive audit trail, documenting the movement of goods through the through the supply chain and capturing critical data at each stage. By enabling detailed batch tracking, the software helps businesses demonstrate demonstrate compliance with industry standards and government regulations. regulations. This visibility ensures prompt identification and removal of any of any problematic products, mitigating the risk of costly recalls or hefty fines. hefty fines.

Conclusion and Key Benefits In conclusion, Transgenie s product traceability software offers a powerful powerful solution for tracking and managing product batches across the supply the supply chain. By capturing critical data and integrating with existing systems, existing systems, it enables companies to enhance quality, ensure compliance, compliance, and respond quickly to potential issues.

THANK YOU ! Visit us: Email Address contact@transgenie.io Office Location 8 The Green, Ste A, Dover Delaware, DE 19901, USA Phone Number +91 770 888 9555 Website www.transgenie.io