General Considerations in Propeller Design

This informative content delves into the key considerations in propeller design, covering aspects such as propeller RPM, number of blades, pitch ratio, blade area ratio, propeller diameter, aft rake, skewback, radial distribution of loading, blade outline shape, and blade sections. It also discusses methods like the Methodical Series Data and the MARIN-B Series for designing efficient propellers for various applications.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

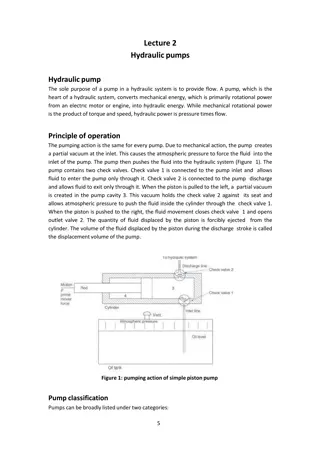

General Considerations in Propeller Design-1 Propeller Rpm: Determined by the propulsion plant. Resonance risk with the natural frequencies of vibration of the hull and shafting system High rpm may increase propeller cavitation risk Low rpm results in large propeller diameter (high effiecency) Number of blades: The larger number of blades the smaller is the exciting force per blade. The smaller number of blades the greater is the opt,mum propeller diameter (higher efficiency but heavier propeller) Pitch ratio: Governs the power that it will absorb in given operating conditions Blade area ratio: Considerations of cavitation. Propeller Diameter: Clearances are important

General Considerations in Propeller Design-2 Aft Rake: Increase the clearances between the hull and the propeller tips and leading edges. Results in higher efficiency But causes an increase in the bending moment due to the centrifugal forces since requiring thicker blades (lower efficiency) Slow running propellers may have a rake aft up to 15 degrees, but in high rpms aft rake is best avoided Skewback: Results in a lower magnitude of unstready forces generated by the propeller in circumferentially varying wake. Heavily skewed blades have low backing efficiencies, are difficult to manufacture and require special strength considerations. The radial distribution of loading: The variation of circulation with Radius upon which the radial distribution of thrust. s normally made optimum for the given average wake at each Radius. May be decrease towards the blade tips to reduce cavitation, blade stress and propeller induced hull vibration.

General Considerations in Propeller Design-3 The shape of expanded blade outline: s chosen in accordance with the radial load distribution. The higher the load the greater the blade width (limit the cavitation) Narrow blade tips result in increase in propeller efficiency but also a greater risk of harmful cavitation. Blade Sections: Naca16, Naca66 sections with a=0.8 and a=1.0 mean lines are used.

The Propeller Design using Methodical Series Data May be used to design both free running and towing duty propellers The MARIN-B Series is widely used for propeller design because it has excellent performance characteristics, particularly for moderate loadings. For heavily loaded propellers used in high speed case, the Gawn Series may be preferred. (segmental blade sections, less cavitation risk)

= 3388 P V R t P kW The Output will be E HESAPLARDA WAGENINGEN B SERISI KULLANILMISTIR 3388 8.2304 411.64 1 0.15 = = = 411.64 (Ship'sresistance) R kN E SECILEN PERVANE = 50. PERVANEDIR T S P/D= .990 J= .791 Kt= .144 10Kq= .266 eta= .683 Bp= 9.6915 delta= 128.0115 T= 484.29 kN Va= 8.230 m/s RHO = 1025.0 kg/m3 Z = 5. EAR = .550 D = 5.500 m Vtip= 32.69 m/s RPS= 1.892 dev/san RPM= 113.50 TORK= 491.217 kNm Pd= 5838.4 kW TAM OLCEGE EKSTRAPOLASYONDA VISKOZ DUZELTME YAPILMAMISTIR = = = = = = T 484.29 (PropellerThrust) kN T 1 Therefore Option 1 can ve used in Program Propcalc 1 1 1 0.15 1 0.20 t w P 1.0625 H 3388 3388 0.739 = = = = 4854 P kW E D 1.0625 0.683 1.050 0.97 0 H R S Data line P D = 0.99(Pitch-to-Diameter Ratio)

The design will be carried on 16 knots of speed. Therefore Option 2 can be used = = = = 5000 0.97 16 w = 4850 P V P V kW D D S ( ) ( ) 1 0.20 = 1 0.5144 6.584 / m s A S ThrustDetermination V : 16 P : 3388 17 4188 S E R :411.64 478.90 T :484.22 563.40 T Pervane Karakteristikleri - Kt/J^4 = 1.109 ---|-------|-------|--------|--------|--------|------------|----------| i P/D J Kt 10Kq eta0 Bp delta ---|-------|-------|--------|--------|--------|------------|----------| 1 .500 .456 .0481 .0757 .4607 20.4646 221.9395 32 .810 .593 .1367 .2035 .6336 17.4500 170.8904 33 .820 .596 .1400 .2094 .6341 17.4429 169.8783 34 .830 .600 .1433 .2155 .6345 17.4380 168.8901 91 1.400 .745 .3419 .7281 .5569 18.6132 135.8922 ---|-------|-------|--------|--------|--------|----- ------|-----------| HESAPLARDA WAGENINGEN B SERISI KULLANILMISTIR SECILEN PERVANE = 33. PERVANEDIR P/D= .820 J= .596 Kt= .140 10Kq= .209 eta= .634 Bp= 17.4429 delta= 169.8783 T= 484.22 kN Va= 6.584 m/s RHO = 1025.0 kg/m3 Z = 4. EAR = .550 D = 5.260 m RPS= 2.100 dev/san RPM= 126.00 TORK= 381.024 kNm Pd= 5027.5 kW TAM OLCEGE EKSTRAPOLASYONDA VISKOZ DUZELTME YAPILMAMISTIR 1 1 1 0.15 1 0.20 t w P = = = 1.0625 H 3388 3388 0.686 = = = = 4938 P kW E B = 1.0625 0.634 1.050 0.97 4938 (Engine power is enough) B P kW = 0 H R S 5000 P kW E P D = 0.82(Pitch-to-Diameter Ratio) D 5.26m(Propeller Diameter) =

CAVITATION CHECK ACCORDING TO SUGGESTIONS UPPER LIMITS OF THE BURRILS MERCHANT SHIPS ( ) ( ) 2 2 = + + = + + 2.1 5.26 = + = 2 2 2 2 2 2 2 0.7 gh 6.584 101.325 1.025 9.81 3.5 1.704 1 1.025 633.42 2 0.1984 R R + 0.7 6.584 24.29 633.42 / V V nD P m s 0.7 R A 134.81 324.62 P = = = = 0.41 A V 1 2 0.7 R 2 V 0.7 R = = 0.0321 0.3886 + 0.16(thrustloadingcoefficient) 1 1 2 2 484.22 9.232 52.45 A 2 0.7 3 0.7 0.0501 0.7 C R C T A = R C = 1.025 633.42 0.16 = 2 2 52.45 / V kN m 0.7 P = = 2 A m P 9.23 9.23 0.879 = = = = 2 10.49 A m P ( ) E 1.067 0.229 0.82 P D 1.067 0.229 10.49 5.26 4 10.49 21.73 A A A D = = = = 0.482 E E 2 2 0 4 Since AE/A0=0.482 is less than the value 0.55, cavitation is OK. Actually the EAR should be reduced to that value and whole calculation is repeated.

Multi-speed gearbox can be used CPP can be used

The following output is obtained Pervane Karakteristikleri - Kt/J^2 = 0.234 i P/D J Kt 10Kq eta0 Bp delta ---|-------|-------|--------|--------|--------|------------|---------| 1 0.500 0.460 0.0495 0.0768 0.4716 20.1862 220.1225 11 0.600 0.530 0.0658 0.0996 0.5575 16.0997 190.8884 90 1.390 0.995 0.2315 0.5230 0.7013 7.6505 101.7378 91 1.400 1.000 0.2339 0.5305 0.7018 7.6101 101.2312 ---|-------|-------|--------|--------|--------|----- ------|-----------| HESAPLARDA WAGENINGEN B SERISI KULLANILMISTIR SECILEN PERVANE = 90. PERVANEDIR P/D=1.390 J= 0.995 Kt= 0.232 10Kq= 0.523 eta= 0.701 Bp= 7.6505 delta= 101.7378 T= 56.13 kN Va= 4.938 m/s RHO = 1025.0 kg/m3 Z = 4. EAR = 0.500 D = 3.100 m Vtip= 15.59 m/s RPS= 1.600 dev/san RPM= 96.02 TORK= 39.303 kNm Pd= 395.2 kW TAM OLCEGE EKSTRAPOLASYONDA VISKOZ DUZELTME YAPILMAMISTIR The pitch ratio P/D=1.39 is impossible for the Bollard Pull Condition due to the cavitation risk. Instead of this P/D=0.51 is used. FirstTrialforFree-RunningSpeed 285 12 0.5144 46.17 1 1 0.18 (1 ) 12 A S V V w = = 285 6.173 P V R = = = = 46.17 R kN E T From the Free-Runningcalculation P D V N J D t w P P S = = = = = 56.13 T kN T 0.60 andJ 0.53( ) from programoutput t ( ) 1 0.2 = 0.5144 4.938 / m s 4.938 0.53 3.1 1 0.18 1 0.2 = = 60 180 = RPM A Therefore the program can be run for the first option to determine optimum RPM for D=3.1 m diameter with the data 1 1 = = = 1.025 H 285 285 0.547 = = = = 521 kW E B 1.025 0.55 1.0 0.97 ial for Bollard Pull 0 H R S (15 ) EnginePower forthe firsttr tons

As a result 880kW@180RPM engine data with the propeller D=3.1 m in diameter and P/D=0.6 pitch ratio is enough for satisfying both free running and bollard conditions at the same time. Therefore the program can be run for the Bollard Pull option to satisfy 15 tons of Static Bollard Pull for D=3.1 m diameter with the following data The program is runned again with the following data Therefore one obtain the following output which contains error Pervane Karakteristikleri ---|-------|--------|-------|--------|---------| i D(m) 10Kq P/D Kt T(N) ---|-------|--------|-------|--------|---------| Yaricap D= 3.100 m Kq=0.0105 ICIN P/D HESABI MEVCUT PERVANE ICIN MUMKUN DEGIL 874.2 < DHP= 521.0 kW< 5321.0 araliginda olmalidir. Datayi buna gore duzenleyin Pervane Karakteristikleri ---|-------|--------|---------|--------|------------|------------| i J Kt 10Kq eta0 Bp delta ---|-------|--------|---------|--------|------------|------------| 1 0.050 0.2329 0.2262 0.0819 8896.8486 2025.3160 3 0.100 0.2194 0.2162 0.1615 1537.6758 1012.6580 7 0.200 0.1894 0.1943 0.3102 257.6870 506.3289 11 0.300 0.1556 0.1695 0.4383 87.3437 337.5526 15 0.400 0.1186 0.1415 0.5333 38.8759 253.1645 19 0.500 0.0785 0.1100 0.5681 19.6169 202.5316 23 0.600 0.0359 0.0745 0.4595 10.2379 168.7763 26 0.675 0.0024 0.0452 0.0568 5.9394 150.0234 ---|-------|--------|---------|--------|------------|------------| Therefore the second trial is carried on 880 kW engine power and 180 RPM rotation rate with the following data HESAPLARDA WAGENINGEN B SERISI KULLANILMISTIR Z = 4 EAR = 0.500 P/D = 0.600 TAM OLCEGE EKSTRAPOLASYONDA VISKOZ DUZELTME YAPILMAMISTIR Pervane Karakteristikleri ---|-------|--------|-------|--------|---------| i D(m) 10Kq P/D Kt T(N) ---|-------|--------|-------|--------|---------| 1 3.100 0.1767 0.502 0.2020 172133. 2 3.100 0.1767 0.502 0.2020 172133. 3 3.100 0.1767 0.502 0.2020 172133. ---|-------|--------|-------|--------|---------| 17.5 tons of Bollard Performance is obtained for P/D=0.502 pitch ratio (17.5=172133/(1000*9.81))

= = 0.24 0.023 K K T = Q = 2 4 0.24*1.025*3 *3.1 /9.81 Q=0.023*1.025*3 *3.1 2 2 *60.74*3 1145 D P Qn = = 20.8tonsBollardPull kNm kW toohigh T = 2 5 60.74 = ( ) 15 = forT=15tons of BollardPull ( 15.79 ) tons 1 0.05 15.79*9.81 0.24*1.025*3.1 0.023*1.025*2.61 *3.1 = = = n= 2.6 1 ( ) rps fromK T 4 = = = 2 5 45.97 ( ) Q kNm fromK Q 2 2 *45.97*2.61 753 ( 880 ) P Qn kW enough kW D As a result 2.61*60=157 RPM rotation rate yields to 15 tons of Bollard Pull with 753 kW engine power.