Gas Testing and Hazardous Atmospheres: Preparation and Safety Guidelines

In environments with potential hazards, it is crucial to prepare for gas testing to ensure safety. This involves identifying the type of gas or atmosphere to be tested, understanding common gases, asphyxiants, irritants, and corrosives, and maintaining equipment for accurate testing. Hazardous atmospheres can result from low oxygen levels, flammable gases, or combustible dust. By being aware of these risks and following proper testing procedures, workers can mitigate potential dangers in confined or enclosed spaces and comply with safety regulations.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

MSMWHS217 Gas Test Atmospheres Prepare for gas testing Test gas Maintain equipment

Topic 1 - Prepare for Gas Testing Not all working environments are safe Some working environments may be hazardous, unpredictable, subject to time pressure, chaotic and expose responders to risk, on land or water, by day or night Some of the situations that you may find hazardous could include: Confined spaces Enclosed and partially enclosed spaces Storage tanks, silos, pits, pipes, shafts, ducts, transport vehicles and ships Testing as part of issuing a work permit Monitoring as part of working under a work permit

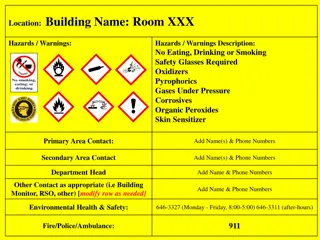

Find Out Type of Gas/Atmosphere to be Tested Testing involves the use of electronic test apparatus In a typical scenario an individual may be required to carry out gas testing of an atmosphere prior to entering a specific area or workspace Hazardous Atmosphere A hazardous atmosphere occurs when: The atmosphere does not have a safe oxygen level The concentration of oxygen in the atmosphere increases the fire risk The concentration of flammable gas, vapour, mist or fumes exceeds five percent of the lower explosive limit for the gas, vapour, mist or fumes Combustible dust is present in a quantity and form that would result in a hazardous area

Common Gases Common chemical asphyxiants may include: Hydrocarbons - an organic compound made of carbon and hydrogen and found in coal, crude oil, natural gas, and plant life Carbon dioxide - a colourless, odourless, non-flammable and slightly acidic liquefied gas Carbon monoxide - a gas and is found in air Hydrogen cyanide - a systemic chemical asphyxiant Hydrogen sulphide - Toxic and flammable gas with an obnoxious odour, formed during decomposition of organic matter, but generated largely by oil burning and refining processes

Common Irritants and Corrosives There are several common irritants and corrosives, including: Chlorine - a chemical element that can be found in liquid, gaseous, or solid state Ammonia - essential for many biological processes and serves as a precursor for amino acid and nucleotide synthesis Acid bases

Common Flammable Gases There are many flammable gases that may need to be tested for when working on site They include: Acetylene - a colourless, combustible gas with a distinctive odour Petroleum - a general term for oil and natural gas Methane, Ethane, Propane, Butane - Natural gas liquids are hydrocarbons - in the same family of molecules as natural gas and crude oil, composed exclusively of carbon and hydrogen

Explosive Range, Upper and Lower Explosive Limits Mixtures of dispersed combustible materials (such as gaseous or vaporised fuels, and some dusts) and air will burn only if the fuel concentration lies within well-defined lower and upper bounds determined experimentally, referred to as flammability limits or explosive limits Combustion can range in violence from deflagration, through detonation, to explosion

Explosive Range, Upper and Lower Explosive Limits Lower Explosive Limit (LEL) The LEL is the lowest concentration (percentage) of a gas or a vapour in air capable of producing a flash of fire in presence of an ignition source (arc, flame, heat) The term is considered by many safety professionals to be the same as the lower flammable limit (LFL) Upper Explosive Limit (UEL) Highest concentration (percentage) of a gas or a vapour in air capable of producing a flash of fire in presence of an ignition source (arc, flame, heat) Concentrations higher than UFL or UEL are "too rich" to burn

Select and Calibrate Equipment in Accordance with Procedures and Find Out Gas Testing Regime/Sampling Pattern Required Tools And Equipment There are a variety of tolls and equipment that you can use to measure and test the quality of air and gases This section will discuss the use of equipment and tools such as: Portable instruments Radiation detectors Sampling tubes and pumps Oxygen level meter Carbon monoxide detector Combustible gas detectors

Types of Gas Detectors Gas detectors can be classified according to the operation mechanism (semiconductors, oxidation, catalytic, infrared, etc.) Gas detectors come packaged into two main form factors: portable devices and fixed gas detectors Portable detectors are used to monitor the atmosphere around personnel, and are worn on clothing or on a belt/harness Fixed type gas detectors may be used for detection of one or more gas types

Measurement of Toxic Gases Electrochemical Sensors Gas detectors measure and indicate the concentration of certain gases in an air via different technologies They function via electrodes signals when a gas is detected Metal Oxide Semiconductors Metal Oxide Semiconductors, or MOS, are also used for detecting toxic gases (commonly carbon monoxide) and work via a gas sensitive film that is composed of tin or tungsten oxides The sensitive film reacts with gases, triggering the device when toxic levels are present

Measurement of Combustible Gases Catalytic sensors represent a large number of gas detector devices that are manufactured today This technology is used to detect combustible gases such as hydrocarbon, and works via catalytic oxidation The sensors of this type of detector are typically constructed from a platinum treated wire coil As a combustible gas comes into contact with the catalytic surface, it is oxidized and the wiring resistance is changed by heat that is released

Radiation Detector Also known as particle detectors, radiation detectors are devices that are designed to identify the presence of some type of radiation within a given area Along with locating pockets of radiation, most radiation detector devices of this type also measure the amount of radiation within the immediate area There are many different types of radiation detectors in common use today The Geiger counter is one example This device is often used to track and locate objects that are charged with high energy particles

Sampling Procedures There are two basic methods for collecting gaseous samples In one, called grab sampling, an actual sample of air is taken in a flask, bottle, bag or other suitable container; in the other, called continuous or integrated sampling, gases or vapours are removed from the air over a measured time- period and concentrated by passage through a solid or liquid sorbent The first method involves the collection of samples over a period of a few seconds up to a minute or two During integrated sampling, the gas or vapour is collected from air by a) solution in a liquid, b) reaction with a solution (or reagent therein), or c) collection onto a solid sorbent

Oxygen Level Meter Levels of oxygen within a confined space that are too low (below 19.5%) or too high (above 23.5%) are a major hazard The oxygen levels inside a confined space may fall below a safe level for the following reasons: The combustion of flammable materials (for example welding or cutting) Slow bacterial reactions of organic substances (for example sewerage) Reaction of inorganic substances (for example rust) Oxygen absorbed by materials (for example grain in silos) Oxygen displaced by another gas (for example nitrogen used to remove toxic fumes) High oxygen consumption rate (for example many people working in a small confined space)

Carbon Monoxide Detector Carbon Monoxide (CO) is a colorless, odorless, tasteless poisonous gas It is a common industrial hazard resulting from incomplete burning of natural gas and any other material containing carbon such as gasoline, kerosene, oil, propane, coal, or wood Typical applications where dangerous levels of Carbon Monoxide (CO) might occur and benefit from a Carbon Monoxide gas detector are: Boiler rooms Breweries Warehouses Petroleum refineries

Combustible Gas Detectors Combustible gas detectors are required whenever there is a possibility of a hazard to life or property caused by the accumulation of a combustible gaseous atmosphere The Combustible gas detector provides the user with a means of detecting the presence of the combustible gas The combustible gas detector then issues suitable audible or visual warnings and/or take the specific actions necessary such as increased ventilation, plant shutdown, evacuation or other safety procedures as warranted

Calibration All gas detectors must be calibrated on a schedule Of the two form factors of gas detectors, portables must be calibrated more frequently due to the regular changes in environment they experience A typical calibration schedule for a fixed system may be quarterly, bi-annually or even annually with some of the more robust units A typical calibration schedule for a portable gas detector is a daily "bump test" accompanied by a monthly calibration Almost every portable gas detector requires a specific calibration gas which is available from the manufacturer

Challenge (Bump) Test Because a gas detector is used for employee safety, it is important to ensure it is operating perfectly Australian standards specify that a person operating any gas detector is strongly advised to check the gas detector's performance each day, and that it is maintained and used in accordance with the manufacturer s instructions and warnings A challenge test should consist of exposing the gas detector to a known concentration of gas to ensure that the gas detector will respond, and that both the audible and visual alarms activate

Find Out Gas Testing Regime/Sampling Pattern Required In all cases there should be a regime or checklist set up to determine the frequency of testing Your organisation will have a standard regime for testing and you should ensure you know and follow each procedure for testing If you are wearing a personal gas testing device you will be monitoring the atmosphere constantly You should ensure your device is tested; calibrated and new batteries are installed or charged on a daily basis to ensure the device is working effectively

Identify Hazards From Possible Atmosphere Contaminants Health Hazards Hazard is the potential for an agent or process to do harm Risk is the likelihood that an agent will produce injury or disease under specified conditions Toxicity refers to the capacity of an agent to produce disease or injury Common Routes of Entry into The Body The most common methods of entry of contaminants into the human body include: Inhalation Localised exterior contamination Absorbed through the skin Ingestion

Implement Hazard Control Measures and Use of Appropriate Personal Protective Equipment (PPE) Prevention and Control Measures There are many types of control measures relating to gas control in a workplace All of them are based on the hierarchy of control Eliminate the hazard Substitute the hazard with a lesser risk Isolate the hazard Use engineering controls Use administrative controls Use personal protective equipment

Topic 2 - Test Gas Use Gas Testing Equipment to Test Gas as Required and Interpret and Report Readings We have discussed gas testing equipment in the previous topic and each piece of equipment will vary in standard operation so you will need to follow the manufacturer s instructions on the operation of the equipment Oxygen Analyser Radiation Detector

Oxygen Analyser The C-Squared Oxygen Analyzer is designed to measure oxygen levels in the 0.1 to 100.0% range It can be used to measure the oxygen content for mixes used in Diving, Medical Instrumentation and Industrial applications The Analyzer is designed to be able to verify oxygen concentration in cylinders as well as analyze delivery systems

Radiation Detector Get the GM counter and batteries from storage; prepare the instrument and determine background level Position the Geiger counter with the meter away from you Locate and open the battery compartment Put the batteries in the meter using proper orientation (up/down) Close and latch the battery compartment Check the batteries using the "range" switch or "bat" button; the method depends on the type of instrument Turn the "F/S" switch to "S" (Slow) Turn the "audio" switch to "ON"

Monitor Gas On an Ongoing Basis as Required and Take Required Action If Readings are Unacceptable and Communicate Required Actions to be Taken to Appropriate Personnel Monitoring gas in a workplace should be an ongoing action Your workplace will have procedures relating to continuous or regular monitoring you will need to adhere to ensure the health and safety of all people working or in the vicinity of the site or building Please ensure you know and understand these procedures and follow them at all times to maintain compliance and ensure safety for all concerned

What to do if Carbon Monoxide is Detected? If you find out that a significant amount of carbon monoxide (CO) is present, there are things you need to do for you and your colleague s safety: Turn off source of CO, if possible to do without endangering yourself or others If indoors, move outside to fresh air immediately If you are outdoors, move far away from the source of CO Call 000 if anyone is exhibiting symptoms of CO poisoning Report your detection to your supervisor

What to do if Oxygen Levels are Detected as Low? Potential Effects of Oxygen Enriched and Deficient Atmospheres Breathing equipment must be used in situations where oxygen deficiency is expected and which cannot be remedied by adequate ventilation Gas masks are with-out exception useless for this purpose, as they only filter out gases Recommended types of breathing equipment are: Self-contained breathing apparatus using air cylinders Fresh air masks where the mask is connected via a hose of adequate length and diameter to a fresh air supply Periodic inspection of the equipment shall be carried out and the user of this type of equipment should be adequately trained

Communicate Required Actions to be Taken to Appropriate Personnel It is essential that all required actions that need to be taken in order manage risks and hazards that may be present due to air contaminations are communicated promptly, correctly and appropriately to all appropriate personnel to ensure that all personnel are aware of actions required and that no further risk is applied due to the lack of communication of miss-communication

Topic 3 - Maintain Equipment Clean and Maintain Gas Testing Equipment in Accordance with Procedures and Inspect and Fault-Find Monitoring Equipment in Accordance With Procedures There will be different maintenance and cleaning instructions depending on the type of equipment Oxygen Analyser Instructions Radiation Detector Maintenance Guide

Return Gas Testing Equipment to Required Location and in Required Condition and Maintain Records of Tests and Results in Accordance With Procedures Storage Once you have completed your gas testing and have finished cleaning and checking your piece of equipment you should ensure it is replaced where it should be This will mean that all equipment must be kept in a dry zone out of weather and moisture and direct sunlight

Record Keeping You are required to keep records of all inspections, test and maintenance carried out on your equipment that operates in or is affected by a hostile operating environment In particular, the following information must be recorded: The name of the person who carried out the inspection, test or maintenance The date or dates the inspections , tests or maintenance was carried out The result or outcome of the inspections, tests or maintenance The date when the next inspection and test must be carried out

Records and Information Must Be Kept Records relating to hazards in the workplace, relevant State/Territory OHS Acts, Regulations, Standards and Codes of Practice, need to be kept at the workplace The employer association or local OHS authority in every State/Territory can provide a list As legislation and associated standards are subject to change, employers need to check periodically to ensure that they are complying with a current version

Safe Work Procedureshazardous Atmospheres See AS/NZS 3000:2007 for guidance on electrical testing and fault finding in hazardous atmospheres that presents a risk to health and safety from fire or explosion Record Keeping Requirements A person conducting a business or undertaking carrying out electrical work must keep: A copy of the risk assessment until at least 28 days after the work to which it relates is completed A copy of the safe work method statement until the work to which it relates is completed

Topic 4 Required Knowledge Gas Test Atmospheres Organisational Procedures, Including: Work Permit Systems As a part of the legal work health and safety requirements for working in confined spaces or areas where there is a possibility of a gas leak or hazardous environment it may be necessary for a work permit to be attained ensuring that the space has been deemed safe and all necessary rectifications have been made to the area prior to personnel entering the area and commencing work

Incident, Fire and Accident Throughout Gas test and risk control procedures there may be a range of incidents accidents or fires, it is essential that all staff are aware of what to do in the case of any emergency situation such as these: Emergency procedures Typical evacuation procedures Control of small fires - identification, selection and operation of the appropriate extinguishing mediums for various types of fires, general fire prevention methods and the precautions for personal protection when fighting small fires Fire extinguishers Using an extinguisher to fight a fire

Incident, Fire and Accident Use of a fire hose Use of a fire blanket Personal protective equipment when fighting small fires Confined space rescue Delivering first aid CPR Two person CPR Single person CPR Cardio pulmonary arrest Defibrillation Dealing with A patient with an altered level of consciousness Organisation standard operating procedures (SOPS)

Common Atmospheric Hazards and Contaminants When working in a confined space there are a range of common hazards that must be identified if they are present so that suitable action is able to be taken and these may include: Death Asphyxiation Diseases and illness Breathing and airway damage Explosions Fire

Exposure Standards (Time-weighted Average, Short-term Exposure Limits, Peak Limitation Values, and Examination of Toxic Effect at the Level of a Range of Flammable Gases) Workplace exposure standards are a range of parameters and limits that apply to the exposure of personnel to a range of air borne or atmospheric contaminants. There are three types of exposure limits and these are: Time-weighted average Short-term exposure limits Peak limitation values Examination of toxic effect at the level of a range of flammable gases Conditions under which atmospheres become hazardous Units of measurement used to express concentration of atmospheric contaminants (mg/cubic m. Ppm, % v/v)

SUMMARY Now that you have completed this unit, you should have the skills and knowledge to test the working atmosphere, using electronic test apparatus, to find out if it is safe for the proposed work