FY25 LBS Lab OMEGA/OMEGA EP Proposed Campaign

Proposed campaign in FY25 by the LBS Lab to measure specific deliverables, compare results with experimental and theory PIs, collaborate with others, and assess technical issues such as target fabrication feasibility. The campaign involves motivation, relevant milestones, previous/simulated results, experimental configuration, and target schematics. Detailed information on experimental plan, facility scheduling, and target design is outlined.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

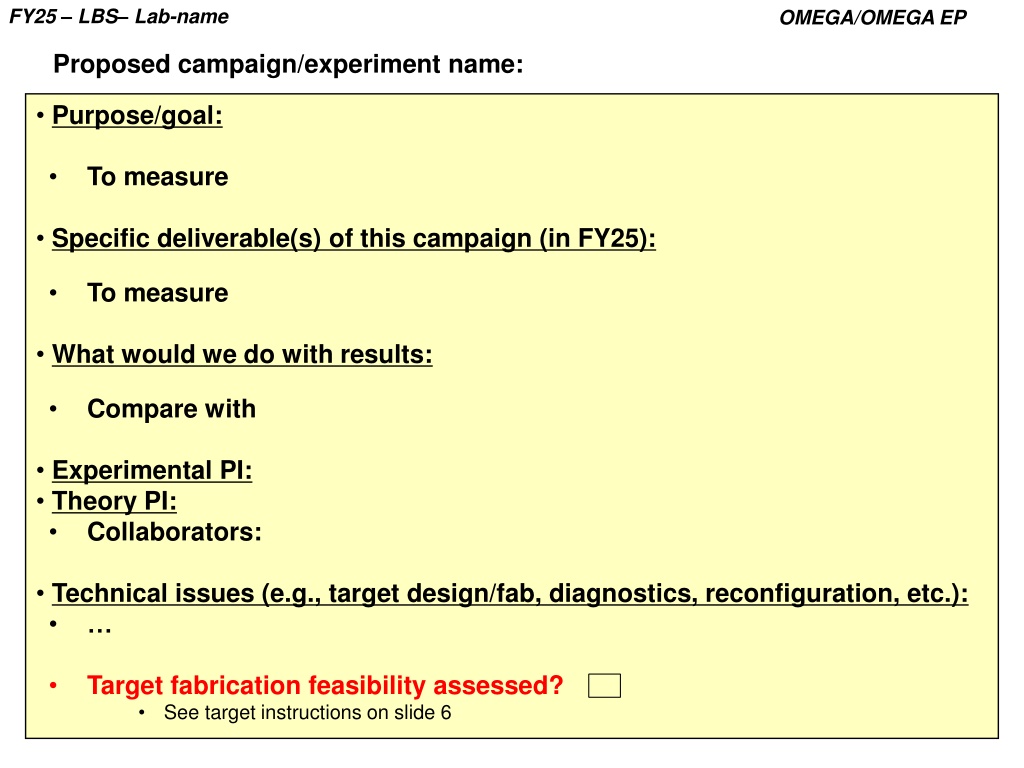

FY25 LBS Lab-name OMEGA/OMEGA EP Proposed campaign/experiment name: Purpose/goal: To measure Specific deliverable(s) of this campaign (in FY25): To measure What would we do with results: Compare with Experimental PI: Theory PI: Collaborators: Technical issues (e.g., target design/fab, diagnostics, reconfiguration, etc.): Target fabrication feasibility assessed? See target instructions on slide 6

FY25 OMEGA/OMEGA EP Proposed campaign/experiment name: Motivation and campaign overview Campaign motivation and deliverables Long-term campaign plan, endpoint, and applications Relevant milestones

FY25 OMEGA/OMEGA EP Proposed campaign/experiment name: Previous and/or simulated results Results of prior experiments and their impact on the current proposal Hypothesis to be tested Simulations of proposed experiments or expected results

FY25 OMEGA/OMEGA EP Proposed campaign/experiment name: VISRAD model configuration or schematic for the proposed experiments To assess experimental plan: technical details and feasibility Include all components not expected to survive the shot, driven or undriven, with scale

FY25 OMEGA/OMEGA EP Proposed campaign/experiment name: Experimental configuration (information for facility/scheduling) No of shots or days required: Schedule request (by quarter, FY25): (Please indicate if your experiment could be ready for shots in Q1.) (Requesting Q1 and Q2 is preferred) Facility (OMEGA or EP or Joint): You must unambiguously provide the following information for each configuration on each shot day covered by this 6-page summary: Beam configuration: OMEGA 60: Number of beams , Number and Type of DPPs, 2w/3w/4w probe beam (if required), and experiment axis OMEGA EP: Specify required mode (SP, SP CoProp, UV, or T-OPA) for each of the four beams Primary diagnostics: List all required diagnostics (fixed or TIM-based) Indicate any new diagnostic qualification or existing diagnostic modification required Targets: DT or DD, Special Fills, Planar Cryo Will Gas Jet be used and, if so, is a new nozzle design required? Will MIFEDS be used and, if so, is a new coil design required? For EP, all components not expected to survive the shot, driven or otherwise, must be identified including scale, to determine if the OAP dds will be required Targets contain Z>36 material: (Yes/No) Spectrometer in use (Yes/No)

FY25 OMEGA/OMEGA EP Target schematics, definition and number for the proposed experiments PI s and PI s institution are responsible for targets for the proposed experiment. PIs are urged to discuss target needs with their target provider/supplier before submitting proposals and confirm the discussion in the proposal. Here are some general instructions provided to NLUF PIs which you may find useful. Define whether this is an existing target design, and if not what development is required If the target design differs from targets fabricated previously, provide sufficient technical detail to allow the complexity and feasibility of the target to be built to be properly assessed Indicate if components will be provided by other institutions aside from General Atomics (GA) or LLE Indicate if assembly will be completed by other institutions aside from GA or LLE Include targets diagrams with materials, dimensions and number of assembled targets Indicate number of variations which include different outer diameters (ODs), thickness, materials, etc Indicate materials of each layer, CH vs metal (specially if the request requires Beryllium) Indicate number of gas fills and pressures required, especially if the request will require D3He/ DT to coordinate with LLE Indicate If targets will be attached to MIFEDS to coordinate with LLE Include pie diagrams for capsules request and developmental targets Specify density and tolerances for foam and 2pp targets requested Specify tolerances for all dimensions Table 1 refers to typical tolerances for different materials of capsules GA fabricate (these values are meant as guideline only, they may not cover all different cases/campaigns) Define acceptable surface roughness if it is a critical parameter Define glue layer thickness/quality and/or glue spot size/quality for the stalk mounting if they are critical parameters Table 1. Typical tolerances for capsule fabrication For target assembly For each target type and configurations specify target positioner and critical surface normal Critical assemble angles and tolerances Material for capsules CH Doped layer at% Metal Multilayer metal thickness <1 m - flip coating Metal Multilayer metal thickness >1 m - flip coating Metal Multilayer metal thickness >1.5 m - roll coating Hoppe glass wall thickness <4 m Hoppe glass wall thickness >4 m Metal only roll coating e.g. Be OD tolerance ( m) Layer thickness tolerance ( m) Detail CH SiCH/GeCH/CuCH SiCH/GeCH/CuCH 20 20 NA 25 25 25 50 50 25 1 1 1 0.2 0.5 1 0.5 1 2