Factors Influencing Mining Method Selection

Factors affecting the selection of a mining method include the shape and size of the deposit, the deposit's contact with country rock, thickness of the ore body, and the dip of the deposit. The shape of the deposit, contact with country rock, and thickness of the ore body impact the feasibility and efficiency of mining operations. The dip of the deposit influences the choice of mining method, with considerations for safety, rock fragmentation, and material transportation. Understanding these factors helps in determining the most suitable mining approach for a given ore deposit.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

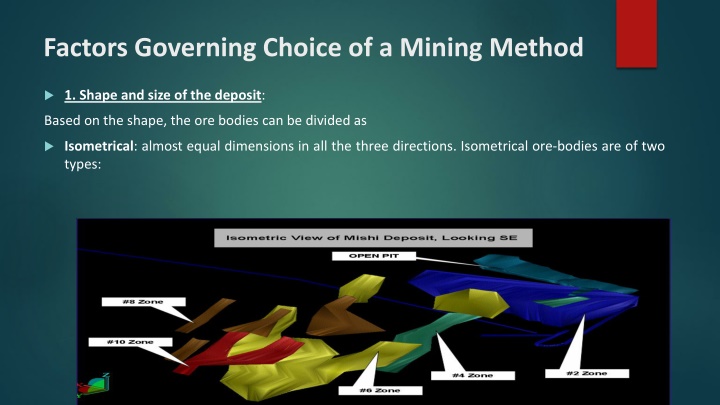

Factors Governing Choice of a Mining Method 1. Shape and size of the deposit: Based on the shape, the ore bodies can be divided as Isometrical: almost equal dimensions in all the three directions. Isometrical ore-bodies are of two types:

(i) Stock and Nests: These are usually irregular in shape but having almost equal dimensions in all directions. Massive deposits fall in this category. Stocks can have dimensions even in kilometres, whereas nests are limited in size, within several meters. (ii) Columnar: extended in one direction downward. As the name suggests columnar deposits are like a column. Many of Diamond deposits are the examples of columnar deposits. These are also known as pipe deposits, which are almost vertical and thin, and extending in depth.

Sheet: extended in two directions. The sheet deposits are having almost a constant thickness. Coal seams and ore veins are considered in this category. But the veins usually do not have uniform thickness. Tabular deposits fall in this category. Lenses are considered to be a change from first to third group, having irregular shape and unequal dimension in all the three directions.

2. Deposits contact with country rock: This aspect is also important as sharp and distinct contact of the deposit with country rocks makes the mining process easier. Massive ores (ore minerals combined with small amount of rock) have well defined contact with the country rock. In other cases, such as impregnation ores (ore rocks with small ore minerals) have no sharp contact with country rocks.

Thickness of deposit Ore body thickness is a normal distance between footwall and hanging wall. If distance is measured along the normal direction, then it is termed as true thickness. But when it is measured vertically or horizontally then vertical thickness or horizontal thickness. In very thin deposits floor stripping becomes essential. For very thick deposits ore mining from hanging wall towards footwall (transverse stoping) becomes essential. Very thin deposits Thin deposits: thickness range. Medium thick deposit: thickness range Thick deposit: thickness range Very thick deposit Types of deposits(thickness wise) Thickness in metres thickness less than 0.7m. 0.7 2m 2 5m. 5 20m. thickness exceeding 20m.

Dip of the deposit Dip of the deposit is one of the most important parameters, which governs a mining method/system. Classification:- Flat dipping: 0 to below 20 . Inclined dipping: from 20 to below 50 . Steeply inclined dipping: exceeding 50 . Following are some of the important aspects regarding dip: Roof pressure decreases with increasing depth. Low dip provides firm foothold. Influence of dip during rock fragmentation. With increasing dip, the loading and transportation of the broken muck becomes easier.

5. Physical and mechanical characteristics of the ore and the enclosing rocks Factors affecting the mechanical strength:- Hardness, toughness, jointing, laminations, presence of foreign inclusions and intercalation. Strength of rocks has influence on selection a mining method as this feature has got a direct bearing on selection of mining equipment and tools, also assessing the consumption pattern of materials (explosives, drilling accessories etc.), labour productivity and cost of extraction. In underground mining the stability of ore and country rock is equally important as the rock strength. Stability is the ability of a massif, undermined (exposed) from beneath or sides, to resist caving for a certain period of time. Apart from the physical and mechanical properties of the rock massif, stability is also affected by many other factors:- 1.Depth of workings 2.Cross section 3. Size & Shape Immediately after exposure the rock seldom shows signs of instability but in due course of time it starts loosing stability due to rock pressure, and atmospheric conditions, and thereby it starts caving.

Divided into four groups as outlined below: Very unstable ores and rocks:The rocks, which do not allow any exposure of roof and walls and need advanced timbering; such rocks and ground are: quick and, loose and water saturated strata etc. Unstable ores and rocks: In this type of strata the roof/back needs a strong support immediately after its exposure. Medium stable ores and rocks:This type of strata permits exposure of the roof over a comparatively large area and requires support if the roof exposure is to be allowed for a considerable time period. Very stable ores and rocks : This type of strata can allow exposure for sufficient time and space without causing caving. Strata of this kind are rarely encountered comparing the same with the previous two groups. Roof Pressure: Roof pressure over a worked out space depends upon the texture of rock constituting the roof/back, its coherence, dip of the deposit, span, and rate of mining and duration of its exposure.

6. Presence of geological disturbances and influence of the direction of cleats or partings Geological disturbance includes presence of any one of them or combination of more than one of structures such as fault, folds, joints, fissures, dykes etc. These structures usually require extra care in terms of strata stability, water seepage, gas leakage etc. making the mining process sometimes more tedious and slow. Presence of such structures usually result into higher costs and decline in productivity. The fissures running parallel to strike can be mined by overhand or underhand stoping. If the transverse fissures, which run almost parallel to the dip, penetrate deposit, it should be mined adopting breast stoping. The worked out space should be either backfilled, or caving of the roof (back) should be allowed.

7. Degree of mechanization and output required Mechanization means performing the underground operations using machines. Degree-1 mechanization:Conventional pusher leg drills, rocker shovels, loco haulage and blast hole drills of 50 60mm. dia. Degree-2 mechanization means use of jumbos, trackless equipment such as LHDs(1 cu. yd. capacity or more), low profile dumpers and small capacity trucks. Drilling in stopes is by the same drills as in degree-1 mechanization. Degree-3 mechanization has the same set of machines as in degree-2, except that the drilling (for stoping) is by the down-the-hole drills capable of drilling holes of 150 200mm. dia. of 40m length. In some situation the production requirements or the market demands select a mining method. Higher output warrants selection of bulk mining methods for which use of equipment of higher capacity and heavy duty becomes essential. The various sets of equipment used for this purpose are costly and require a huge sum of capital investment, and if not effectively utilized, leads to low productivity and higher overall costs. But when utilized properly, the cost of mining is substantially reduced.

8. Ore grade and its distribution, and value of the product Ore grade plays a vital role in selecting a mining method. Low-grade deposit can be mined out profitably if bulk-mining methods are applied. High -grade deposit cans be mined out by any of the mining methods and even up to a great depth. The more homogeneous a deposit, the less difficult it is to evaluate and mine out.eg-Gold Table : Proportion of valuable content in mineral deposit Ore value is the focal point while selecting a mining method. The cut-off grade further decides ore reserves, as mineral reserves in any deposit below cut-off grade are considered waste and the one at and above cut-off grade as ore reserves.

9. Depth of the deposit 10. Presence of water Deepening of workings below 600 800m is often accompanied by a considerable rise in rock pressure, thus impeding the use of some systems. Ores may be wet, dry or damp. Ore s moisture promotes caking and freezing during winter. Pumping cost is added. Acidic water adversely affects health and safety of the workers. Abrupt inrush of ore or rock burst from the stressed pillars is a phenomenon that has been encountered at very deep horizons. A proper drainage system means improvement in the haulage productivity and better life of mine track and roads. At greater depths apart from rock stability, the problems of heat and humidity equally arise. Presence of water during deep mining causes the problem of humidity. But relief from the occurrence of rock bursts were felt when the filling material was replaced by concrete fill and changing stoping method to stope drive. Apart from this, cost of ventilation, support, drainage, hoisting, transportation also increases

11. Presence of gases 12. Ore & Country rocks susceptibility to caking and oxidation Caking:-Some ore deposits are associated with small fractions of clays or some sticky material causes problems after their fragmentation, as these clay or sticky materials after getting wet during their mining may result into cakes which are large immovable hard-to-loose solids. This phenomenon causes problems during ore drawing from as tope; due to ore mass bridging and plugging of ore passes. Oxidation: Ore containing more than 40% sulphur in the form of pyrite or pyrhotite, etc. are liable to fires and thus, most hazardous. The pyrites ores after the fragmentation and prolonged storage, may cause intensive heating due to their self- oxidation. In a coal deposit presence of methane gas is common. Some other gases emitted in mines, prominent amongst them are: carbon dioxide CO2, hydrogen sulphide H2S, sulphur dioxide SO2, and few others. Presence of these gases adds to ventilation costs and needs extra care towards safety. Special care is required while selecting and designing a mining method to win sulphur, uranium, pyrite and coal.