Engineering Materials & Metallurgy

Delve into the fundamentals of engineering materials and metallurgy, exploring the history, range of materials, optimum use criteria, and factors influencing material selection. Learn about component shapes, dimensional requirements, mechanical properties under static and dynamic loads, as well as fabrication and service requirements. Explore the economic aspects such as the cost of materials, processing, and availability. Discover the classification of materials including metals, alloys, polymers, ceramics, composites, and advanced smart materials. Gain insights into the properties of materials, encompassing physical, mechanical, thermal, electrical, magnetic, optical, and chemical characteristics.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

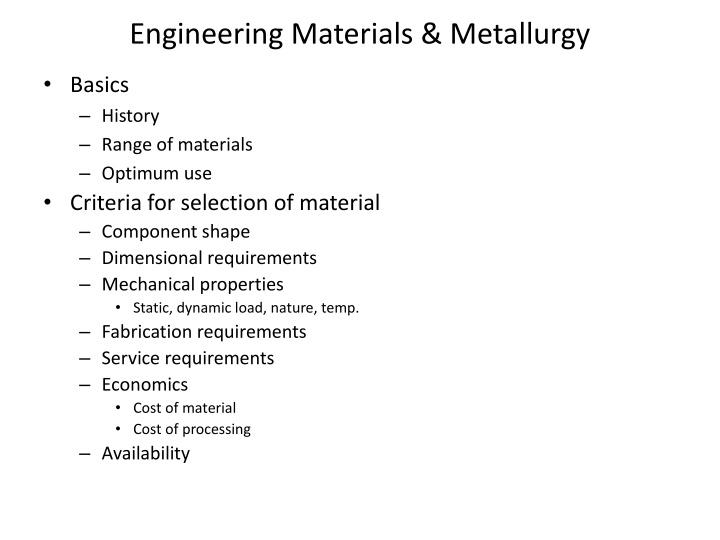

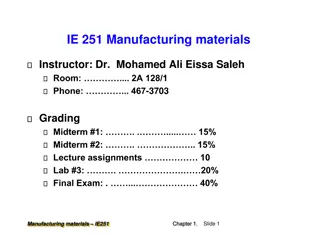

Engineering Materials & Metallurgy Basics History Range of materials Optimum use Criteria for selection of material Component shape Dimensional requirements Mechanical properties Static, dynamic load, nature, temp. Fabrication requirements Service requirements Economics Cost of material Cost of processing Availability

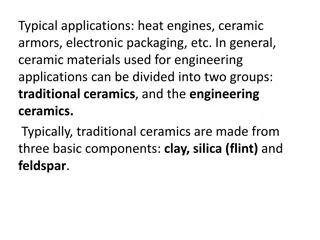

Classification of Materials Metals & Alloys Pure metals Alloyed metals Ferrous Non-ferrous Sintered metals Clad metal Polymers Thermoplastic, thermosetting, nylon, polythene, phenol / urea formaldehyde Ceramics Rock, sand, quartz, granite ,glass, cement, tiles, china ware Composite Two or more material, rcc, fibre glass, tyre, Advanced smart materials Semiconductor, biomaterials, smart, nano-engineered Materials of the future Nuclear field, transportation, new source of energy, hydrogen cell, env. aspects, renewable, regenerative, recycle Fe, al, cu, ni, zn brass, bronze iron,steel

Properties of Materials Physical Mechanical Behaviour under load - Elastic, plastic, strength, ductile, hardness, creep, fatigue etc Thermal Electrical Magnetic Optical Chemical Supercoductivity Luster, color, sp gravity, density, etc.

Physical Properties Luster Color for identification, wave length it can absorb Density Mass per unit volume; different for material; identification basis Sp gravity Melting point/ Boiling point pure metals have sharp MP Porosity Affects thermal conductivity, self lubricating bearing Refractoriness alumina, silica, fire clay, magnesite Specific heat Thermal conductivity/ expansion Electrical properties/ Magnetic properties Reflect light when polished; all metal, iodine, graphite

Mechanical Properties Elasticity non permanent deformation Plasticity Strength Ductility Malleability - ability to deform under compression Hardness -resistance to abrasion, wear, scratch, cut Brittleness - fracture without warning Toughness -amt of energy absorbed before rupture Stiffness - to resist deformation Al v/s steel beam (sag) Resilience - resist impact/ shock, absorb energy upto elastic limits Fatigue - under alternating stresses Creep - slow & progressive deform.. at const stress & at high temp - permanent deformation - ability to withstand load - ability to be drawn into wire

Technological Properties Machinability Ease with which can be cut, removed by cutting tools with finish/cost Tool life (abrasion), low power, force, chip formation cutting speed, feed/depth of cut, material (composition/properties), coeff. of friction, machine used/operation, tool material, coolant Mg, Al, Zn & alloys; Grey CI, brass gun metal,Al-cu alloys; ,Ni, Carbon Steel; sinter carbide, SS, white CI Weldability Ability to be welded satisfactorily, least expenses, sound joints Techniques, filler material, flux, shielding env., composition, thermal/ brittle properties, strength at elevated temp., heat treatment, oxidation, Workability Ease with which shape can be given while in solid state w/o cracks Cold/ hot working - ductility Drawing/ squeezing, bending, shearing, extrusion, rolling, spinning Ductility, HT, hot/cold working, alloys

Technological Properties contd Castability Ease with which material can be cast into solid shapes Flow of metal, low shrinkage, low segregation, design of runner/ riser, porosity, strength Malleability Change in shape under compression without rupture Hammering or rolling Hammering Gold, silver, Al, lead tin, Zn, iron Rolling lead, tin, gold, silver, Al, Cu, Ni, iron Thickness of foil is measure

Selection of Materials Component shape Dimensional requirements Mechanical properties Fabrication requirements Service requirements Economics Cost of material Cost of processing Availability Dynamic Process - Trade off