Efficient Material Cost Accounting Practices for Improved Business Performance

Proper management of material costs is crucial for controlling overall production costs and ensuring product quality. This involves effective purchasing strategies, stock control, and pricing policies. Centralized vs. decentralized purchasing methods are discussed, highlighting the benefits and limitations of each approach. By implementing efficient material cost accounting practices, organizations can enhance operational efficiency and profitability.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

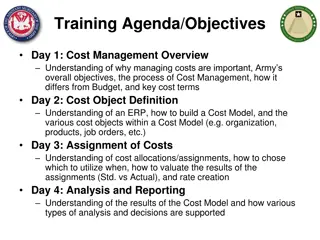

Presentation Transcript

Subscribe my YouTube channel Commerce Yuga & THE FAIR TRUTH https://youtu.be/8bbDzmaAD5o https://youtu.be/5_SkZovAVKU

Introduction- the cost of production of any product is mainly the cost of material used in the production. So to control the cost of the product , it is important to control the cost of the material used. For this the storage, purchasing transfer etc. of the material should be done in proper manner and proper planning. Even a slight mistake in controlling the cost of material may cause a huge loss to the organization. Thus the scope controlling the cost of material spreads from the purchases to the transfer and its proper handing and utilization. controlling the cost of material may be studied in three headings-

1) Purchases of material 2) stock control 3) pricing policies to determine cost of material 1) Purchases of material Quality of the product produced depends up on the quality of material used in production. To ensure the best quality of the material, management must have proper planning. A separate department or group should be given the work of purchases of material. They should be hold responsible for the quality of the martial

Centralized vs. decentralized purchases- here it must be noted that purchases may be centralized or decentralized under centralized purchasing a separate department is formed for all purchasing. Under it no any department has authority to purchase material themselves in small quantity. They send the list of material required to the purchasing department and it makes the material available to them. While on the other hand, under decentralized purchasing every department has authority to buy material as per their requirement. There is any separate purchasing department. Specially when all the unit of the organization same type of product then centralized purchasing is good otherwise decentralized purchasing policy may be adopted

Benefits of centralized purchasing- the following are the main benefits of centralized purchasing 1) economy of bulk purchases 2) expert and talented purchasing staff 3)better control 4) economy in compilation of record 5) adoption of uniform policies 6) proper liaison with various departments 7 ) centralized storage

Limitations of centralized purchasing- 1) Delay in purchasing 2) High initial cost 3) increase in transportation cost 4) chances of misunderstanding 5) No localized purchasing

Purchases cycle. The activities done in purchases cycle may be classified in following- 1) Initiation of purchases- any of the following may initiate the process of purchasing- a) store keeper b) Production planning department c) production department 2) purchase Requisition 3) bill of material

Various factors related to purchases of material- the following factors must be kept in mind before purchasing material a) what to purchases b) when and where to purchases C) how to purchases d) How much to purchases 6) sending purchases order 7) receipt of material 8) inspection 9) payment of bill/ invoice

Classification and codification of material - this is vary important process for the proper control over the cost of material. Here classification means. Categorizing various items on the basis of their nature , use or any other base. while on the other hand codification means providing various alphabetical or numerical sign to any goods so that it can be indentified easily. Types of codification- any of the following- a) Numerical b) Alphabetical c) alphabetical numerical d) decimal method material may be codified using

Bin card- Bin card is the record maintained under the perpetual inventory system by the stores department and shows the quantities of materials received, issued and balance in hand after each receipt and issue. It is also known as stock card or bin tag. ... It records only quantity of materials not the value Two bin system-Two-bin inventory control is a system used to determine when items or materials used in production should be replenished. When items in the first bin have been depleted, an order is placed to refill or replace them. The second bin is then supposed to have enough items to last until the order for the first bin arrives

Store ledger-A stores ledger is a manual or computer record of the raw materials and production supplies stored in a production facility. It is maintained by the person responsible for these assets, such as the warehouse manager Bin Card vs. Stores Ledger The key difference between Bin Card and Stores Ledger lies in the fact that bin card is used in a company to record the transactions of the business which records material received, issued and balance but store ledger is used to record the amount, quantity, type and rate of the material.

Costing of material While costing the value of material we not only include purchases price of material but also transportation and other costs are also included in the value of material. It includes transportation, cowry, store charges, overheads etc. If amount has paid to the supplier in lump sum for the purchases of the material then with the help of invoice cost of each material must try to find out. It is very easy process but problem arises only when many types of material are bought from same supplier and other expenses are mixed.

Books for recording of material 1) material inward book- It can be explained as a register keeping track of all the goods inward. Ex. Whenever a Goods truck from supplier enters premises of the Organization, an entry is made in the inward register to record time and date of inward of goods 2) Material issue book- It is a document which is a classified record of materials issues, returns and transfers. (CIMA). In order to ascertain the cost of materials issued for a job conveniently, it is better to analyze the various Requisition slips since usually there will be a number of them for one job

3) Material return book- when remaining material is returned to store it is recorded in material return book 4) material transfer book- when material is transferred from one department to another, this is recorded in material transfer book 5) Store ledger-A stores ledger is a manual or computer record of the raw materials and production supplies stored in a production facility. It is maintained by the person responsible for these assets, such as the warehouse manager

Requisition Note:- A materials requisition form is a source document that the production department uses to request materials for manufacturing process. The production manager usually fills out the materials requisition form and delivers it to the materials or storage department where all of the raw materials are stored. Pricing of material issued When material is issued from store to various job or contract, the question arises at which price the material should be valued? It is because the value of material is different at different dates. Thus, valuation of material at the time of issue, is called pricing of material. There are various methods of pricing which are as follow-

1) Cost price methods- the followings are cost price methods- 1) FIFO method 2) LIFO method 3) HIFO method 4) Base stock price 5) Specific price 2) Average price method- 1) simple average price 3) Market price method- 1) Replacement price 4) Notional price- 1) Standard price 2) Inflated price 2) Weighted average price 2) Realizable price

FIFO method- First In, First Out, commonly known as FIFO, is an asset-management and valuation method in which assets produced or acquired first are sold, used, or disposed of first. For tax purposes, FIFO assumes that assets with the oldest costs are included in the income statement's cost of goods sold (COGS) Suitability- This method is adopted when 1) price in the market is falling 2) consumption of stock is low

Advantages and The FIFO method has four major advantages: (1) it is easy to apply, (2) the assumed flow of costs corresponds with the normal physical flow of goods, (3) no manipulation of income is possible, 4) Rational method, 5) Use of purchases price 6) stock at market price, 7) useful when prices are falling. disadvantages of FIFO: 1) useless when prices are increasing, 2) difference between market and cost price,3) Problem of storing material

Impact of FIFO method: 1) impact on cost- under this method, production cost does not justify the market price. 2) impact on inventory valuation- valuation of closing inventory is also affected by fluctuation of purchases price. Though, value of stock is near to purchase value so it is also near to current price. 3) impact on profit- there is no impact on profit because production cost and value of closing stock nullify the effect of each other.

LIFO method: The LIFO (Last-In, First-Out) method assumes that the most recent products in a company's inventory have been sold first and uses those costs instead. In short, under this method, the material that is received last is issued first. Under this method issued price is purchases price. Suitability- this method is used when prices in the market are increasing. Advantages of LIFO method: 1) simple method 2) issue at purchase price,3) knowledge of profit and loss,4) useful at the time of increasing price.

Disadvantage of LIFO method: 1) difference in the value of stock, 2) impracticle,3) difference in issue price, 4) problem in storage. HIFO method: Highest in, first out (HIFO) is an inventory distribution and accounting method in which the inventory with the highest cost of purchase is the first to be used or taken out of stock. This method is based on the assumption that closing stock should always remain at the minimum value, so materials with higher value are issued first and get exhausted at the earliest. But this method is not popular as it always undervalues the stock which amounts to creating secret reserves. This method may be used in case of cost plus contracts or monopoly products

Base stock price method: Under this method, a minimum fixed stock of material is always maintained as base stock to meet emergency requirements when there is a delay in supply of raw materials. This is also called safety stock. Any quantity over and above the base stock is issued for production. This method is used in conjunction with either FIFO or LIFO method and base stock method will have the advantages and disadvantages of the method with which it is used. The objective of base stock method is to issue the materials at current prices which can be achieved if it is used with LIFO method, though it can be also used with FIFO method

Specific price method: this method is used when material is bought for a specific job, contract or order and later on issued to the same job or contract. Various cost like transportation cost, inspection cost, freight ect.. Are included in the cost of the material. Advantages- 1) Free form computation: 2) Actual cost of production: 3) actual valuation of closing inventory Limitations: 1) not fit for continuous production 2) Practical problems

Average Cost Method: The principle on which the average cost method is based is that all of the materials in store are so mixed up that an issue cannot be made from any particular lot of purchases and, therefore, it is roper if the materials are issued at the average cost of materials in store. Average may be of two types: (i) Simple Arithmetic Average and (ii) Weighted Arithmetic Average.

A price which is calculated by dividing the total of the prices of the materials in the stock from which the material to be priced could be drawn by the number of the prices used in that total . (C.I.M.A.) Simple average price is calculated by dividing the total of unit purchase prices of different lots in stock on the date of issue by the number of prices used in the calculation and quantity of different lots is ignored. This method may lead to over-recovery or under-recovery of cost of materials from production because quantity purchased in each lot is ignored. Suppose, following are three different lots of materials in stock when the material is to be issued: 1,000 units purchased @RS 10 2,000 units purchased @ Rs 11 3,000 units purchased @ Rs 12 In this example, simple average price will be Rs 11 calculated as below: (Rs 10 + Rs 11 + Rs 12)/3 = Rs 11 i) Simple Average Price:

Simple average price is not to be followed because this method of calculating issue price does not recover the cost price of the materials from the production. In the above example, the purchase price of the material in stock is Rs 68,000 (i.e. 1,000 x RS10 + 2,000 x Rs 11 + 3,000 x Rs 12) whereas the, recovery from the production according to simple average price method will be Rs 66,000 (total quantity 6,000 units issued @ Rs 11 per unit). Thus, there is under-recovery of Rs 2,000 (i.e. Rs 68,000 66,000).

(ii) Weighted Average Price: A price which is calculated by dividing the total cost of materials in the stock from which the materials to be priced could be drawn by the total quantity of materials in that stock. (C.I.M.A.) The weighted average price takes into account the price and quantity of the materials in store.

In the above example, the weighted average price is Rs 11.33 per unit calculated as follows: (1,000 x Rs 10 + 2,000 x Rs 11 + 3,000 x Rs 12)/(1,000 + 2,000 + 3,000) = Rs 11.33 It is better to issue the material at weighted average price method because it recovers the cost price of the materials from production. In the above example, the total purchase price of the materials in stock is Rs 68,000 and the charge to jobs or work orders is also Rs 68,000 (i.e. 6,000 units @ Rs 11.33). In periods of heavy fluctuations in the prices of materials, the average cost method gives better results because it tends to smooth out fluctuations in prices by taking the average of prices of various lots in stock.

Advantages of Average Cost Method: 1. This method is rational, systematic and not subject to manipulation. It is representative of the prices that prevailed during the entire period rather than of the price at the beginning, end, or at one point of issue during the period because it is based on the average of the material costs of the various lots available in the store. 2. Average price method is considered to be the best method when prices fluctuate considerably because this method tends to smooth out fluctuations in prices. 3. Issue prices are not to be calculated each time issues are made. Issue prices are changed only when new lot of materials is received. 4. This method recovers the cost of materials from production. 5. This method maintains the issue prices as near to the market prices as possible. 6. This method eliminates the necessity for adjustments in stock valuation.

4) Notional price method- this method has two method- 1) Standard price- under this method a standard price is determined keeping in mind 1) current price, 2) fluctuation in market value 3) normal quantity of purchases 4) transportation, discount etc.. Generally material is received on various cost but a standard cost is determined to issue the material.

2) Inflated price method- the organization face normal loss due to nature of the material. Some material deplete when it comes in the direct contact of the environment. Such loss can not be avoided. So such loss is known as normal loss. If organization come across such loss it inflates the value of remaining the same proportion. This method is known as inflated price method. For example- if 200 quantity of a material is bought for Rs. 400 and if there is loss of 20 kg. then the new inflated cost will be 400/180= Rs.2.22 per unit

5) Market price method- there are two methods under it A) Replacement price method- price at which material is bought to fulfill requirement of material is called replacement price. This is somewhat tough method. Valuation of material is done at market price. Since material is at present value so current price of the production can be evaluated easily. This method is useful in determining tender value since it is at present price. Its demerit is that the actual price of the production is not known.

B) Realizable price method- the price at which issued material can be sold, is called realizable price. This price may be more and less than actual price of the material issued. This is not very famous method.

Price of material returned to store- if any material is returned after the completion of production then this method should be valued at which it had been issued. If its value is hard to determine then it should be considered the part of last lot issued. If material is valued at average cost then should be valued at the same cost.

Decrease or increase in store- when material is returned to store then it may be found decrease or increase in the quantity of material. a) Shortage of material- if there if shortage of material due to normal loss then the following two treatment may be done- i) normal loss should be shown in issue cost it should be included in factory overhead. Determination of value of normal loss may be done on FIFO or LIFO or other methods. ii) normal loss should be included in material issued and amount should be shown zero but price of rest of material should be inflated.

Abnormal Loss- if there if abnormal loss then it should not be include in material cost rather it should be transferred to costing profit & loss account

Inventory: inventory is often defined as an idle resources of any king, having an economic value in the sense, that raw material can be converted into semi finished goods and with additional value, becomes finished goods. According to P Gopalkrishnan Inventory means a schedule of items held at a particular point of time. - ICMA

Inventory control: inventory is a planned method of determining what to indent, how much to indent and how much to stock so that purchasing and storing costs are the lowest possible without affecting production and sales. - P.R. Gokaran Inventory control may be defined as the planning, ordering and scheduling of materials used in the manufacturing process. - Westing, Fine and Zeng

Objectives of Inventory control: A) Operating Objectives- the followings are objectives- 1. Availability of material 2. Avoidance of wastage 3. Promotion of manufacturing efficiency 4. Better services to customers 5. Determination of different level 6. Efficient system of storage

B) Financial Objectives 1. Optimum investment 2. Minimum cost of inventory 3. Optimum stock turn over

Basic principle of Material control: 1. Co-operation and co-ordination 2. Centralized purchases 3. Indexing classification and codification 4. Inspection of material 5. Following standards 6. Economy in purchases and use 7. Proper arrangement or management of issue 8. Planned storage 9. Internal inspection 10.Determination of stock level 11.Proper record and accounting 12.Selection of material issue price in a right way

Relevant cost for inventory control decision 1. Purchase or production cost 2. Ordering cost or set up cost( TOC= R*C0 /q0) 3. Carrying cost or Holding cost ( TCC= q0*CH/2) 4. Opportunity cost 5. Quantity Discount 6. Stock out of stock

Some important formulas- Maximum Level= order point (Minimum usage rate*Minimum lead time)+EOQ Minimum Level= order point-(Average usage rate*Average lead time) Order point= Maximum rate of usage* Maximum lead time Danger Level= Average usage rate*Emergent lead time Average stock level= Minimum level + * EOQ or (Minimum level+ Maximum level)/2

Cycle time- the time span between two consecutive order is called cycle time. Re-order level- Stock in-hand at the time of placing order is called re-order level. Lead time- the time that is required to transport the order to the firm or the time between placing and receiving order is called lead time. Maximum level- it the maximum amount of quantity that can be with the organization at a particular point of time. Here we also take into account the storage capacity of the firm, availability of the material at a particular season, transportation capacity etc..

Minimum Level- This represents the minimum level of stock with us . Every stock may be up to zero but it can never be negative. Level Time (days) Usages(units) Min 2 5 Normal 3 10 Max 4 15 Let Annual usage = 1600 Ordering cost per unit= 100 Holding cost = 8

Now= Economic order quantity= (2* D* C0) CH EOQ= 2*1600*100 = 200 8 Re- ordering level= 15*4 =60 Maximum level= 60-(5*2)+200= 250 units Minimum level= 60-(10*3)= 30 units Average level= 250+30/2 = 140 units

Ascertainment of slow stock moving- it is very important to find out stock turn over. A slow moving stock increases cost of production moreover there creates some defects in the stock over the time. So it is very important to boost stock turn over. Stock turnover= inventory used at a particular time balance stock at the end of period Material turnover= material used during the period material during the year

THANK YOU KEEP ON LEARNING & Subscribe my YouTube channel Commerce Yuga & THE FAIR TRUTH https://youtu.be/8bbDzmaAD5o https://youtu.be/5_SkZovAVKU