Control of Contaminants in Food: Analysis and Interpretation of Results

This training course presentation focuses on the analysis and interpretation of results in controlling contaminants in food. It covers basic principles, practical cases, and the importance of accurate analytical methods for ensuring food safety and compliance with regulations.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Training course on Control on contaminants in food Phase 2 This presentation has been produced under the contract with the Consumers, Health, Agriculture and Food Executive Agency (CHAFEA). The content of this page is the sole responsibility of NSF Euro Consultants Consortium and can in no way be taken to reflect the views of the Consumers, Health, Agriculture and Food Executive Agency or any other body of the European Union. The Consumers, Health, Agriculture and Food Executive Agency or any other body of the European Union will not be responsible under any circumstances for the contents of communication items prepared by the contractors. Food safety

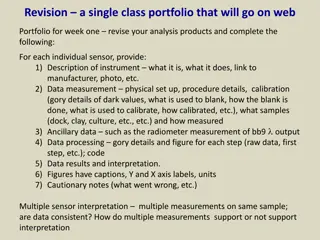

5.3 Analysis and interpretation of results 1.Reminder of the basic principles 2.Practical cases Mr. Carlo Brera 1 Food safety

1. Reminder of the basic principles The laboratory must issue a certificate of analysis according to the following rules: Be accredited for the specific analysis either under a fixed or flexible scope accreditation approach (QA and QC in place) Use of qualified, trained and expert lab-personnel Have checked the correctness in terms of representativeness and reliability of sampling procedures used in the formation of the aggregate sample (sampling report) Form the official aliquots from the enforcement sample in the correct way Have checked the intended use of the product Choose the most appropriate sample preparation (dry or slurry approach) Use the most appropriate validated method of analysis (screening vs confirmatory method) fulfilling the required performance characteristics Calculate the ratio between edible and non-edible part of the product Apply the proper compliance criteria (significative figures, MU, recovery factors, final decision) 2 Food safety

2. Practical cases: Edible part How to interpret your results? The analytical result must be related to the edible part of a food commodity Weight ratio whole product/edible part In some cases the result must be related to the dry matter An accredited analytical method has to be available both for the calculation of the analyte and for the moisture of the sample The result will be compliant with the law according to the use of the product Direct human consumption Subject to further sorting processing or physical treatment such as roasting, cleaning etc. 3 Food safety

2. Practical cases: Mycotoxins in in-shell products 4 Food safety

2. Practical cases How to report analytical results? The analytical result (X) must be reported corrected or uncorrected for recovery. The manner of reporting and the level of recovery must be reported. If an extraction step is applied, the analytical result (X) must always be corrected The analytical result corrected for recovery shall be used for controlling compliance XAVG UEXT 5 5 Food safety

Measurement Uncertainty There is a concern that some laboratories underestimate the size of their uncertainties and report unrealistically small uncertainties to their customers. For chemical analyses, it would not be unreasonable to expect that the (expanded) uncertainties reported by laboratories would be of the following orders: 1000 mg/kg 100 mg/kg 10 mg/kg 1 mg/kg <0,1 mg/kg +/- 11 % +/- 16 % +/- 22 % +/- 32 % +/- 44 % Possible scenarios Measured Value Measurement Uncertainty Max Limit 6 Non-Compliant Compliant Food safety

2. Practical cases: Significative figures Number of significant figures taken into account when reporting results and interpreting them in relation to legal limits Examples: Legal limit of aflatoxin B1 in complementary feeds as set by the Regulation 574/2011: 0,01 mg/kg If your analytical result is 24 g/kg, i.e. 0,024 mg/kg, how to consider it? The result must be reported as 0,02 mg/kg (apparentlynot compliant). But considering MU, the same sample could result not compliant or compliant. 0,013 (Horwitz approach) [COMPLIANT] a. Uext 44% X = 0,024 0,011 = b. Uext 25% X = 0,024 0,006 = [NOT COMPLIANT] 0,018 (Metrological approach) To be reported as 0,02 7 Food safety

2. Practical cases: Slurry How to report the result in presence of a slurried sample By definition the slurry technique refers to a thick mixture of water and the analytical official aliquot. This technique leads to a high level of homogenisation of the sample improving the precision of the final analytical results In case of slurry formation the calculation of the proper edible part to which refer the final result depends on the nature and composition of the sample With shell or any other not edible part Without shell or any other not edible part 8 Food safety

2. Practical cases: Intended use The judgment of the compliance of our analytical official aliquot also depends on the intended use: Question: In terms of intrepretation of results, what is the difference between a product consumption and a product intended for human consumption but to be subject to further commercialisation? intended for direct human physical treatment before Open discussion with participants 9 Food safety

Mixture of ingredients If only one ingredient is present as possible source of contamination, and there is no indication of the percentage present in the product, the result has to be referred to the whole product If more than one ingredient is present with no indication of the percentage of ingredients, the analytical result has to be referred to the main ingredient that coincides with the first one in the list (derived products) If percentage of ingredients is labelled and it is possible to sort out the single ingredients the analytical result has to be referred to single ingredients. In case of non compliance, you can decide to apply the non compliance to the whole product or just to the ingredient. 10 Food safety

How to handle negative results 2. Practical cases Need to express the compliance for total aflatoxins in a pistachio sample for direct human consumption. Legislative basis: Regulation 165/2010/UE Legal Limit for AfB1: 8.0 g/kg; Legal Limit for total AFs : 10.0 g/kg AfB1: 9.9 g/kg AfB2: 4.0 g/kg AfG1: <LoQ (LoQ= 0,5 g/kg)= negative AfG2: <LoQ (LoQ= 0,5 g/kg) = negative Case 1. (uAfB1 = 1,0); Case 2. (uAfB1 = 2,2) Case 1. (uAfB2 = 0,4); Case 2. (uAfB1 = 0,9) (uAfG1 = -) (uAfG2 = -) LOWER BOUND APPROACH How to express the final result for TOT AFs = 13,9 g/kg UextTOT AFs = 2 x (uAfB1)2 + (uAfB2)2 Case 1. UexpTOT AF =2 x [(1,0)2 + (0,4)2] = 2x 1.2 = 2,2 Case 2. UexpTOT AF =2 x [(2,2)2 + (0,9)2] = 2x 5.7 = 4,8 13,9 [NC] 2,2 g/kg 13,9 4,8 g/kg Case 1. Case 2. 11 Food safety [C]

LOQ vs LOD In the field of contaminants, generally LOQ and not LOD must be considered, since no prohibited levels are present. The choice of the most appropriate LOQ depends on different aspects such as: Closeness to the ML (not more of at least 1/4 - 1/6 of the ML) Proper precision values (not more than 10%) Characteristic of the analytical method (screening vs confirmatory) Complexity of the matrix (especially when ELISA or LC-MS/MS or when no clean-up step are used) 12 Food safety

2. Practical cases: Processing factors Article 2 - Dried, diluted, processed and compound foodstuffs When applying the maximum levels, the following shall be taken into account: Changes of the concentration of the contaminant caused by DRYING or DILUTION processes Changes of the concentration of the contaminant caused by PROCESSING The relative proportions of the ingredients The analytical limit of quantification PFs shall be provided by FBOs or in case of no information available, CA can use its own PFs 13 Food safety

2. Practical cases where PFs must be applied How to calculate the compliance? Aflatoxin M1 in cheese 14 Food safety

PFs in cheese The Italian approach On the basis of scientific evidences following ad hoc research studies, the National Committee for Food Safety of the Ministry of Health recommended the following PFs for soft and hard cheeses Soft cheese 3,0 (ML=0,150 g/kg) Hard cheese 5,5 (ML=0,275 g/kg) A new case by case approach is currently under discussion. It is based on the differentiation of AFM1 levels depending on the MFFB (Moisture on a Fat-Free Basis) values (Decision EC/97/80) of the different types of cheese. ?????? ?? ????? ??????? ????? ?????? ?????? ?? ??? ???????x100 15 Food safety

Reg. EU/625/2017 Art. 35 Right of second opinion 1. The competent authorities shall ensure that operators, whose animals or goods are subject to sampling, analysis, test or diagnosis in the context of official controls, have the right to a opinion, at the operator s own expense. The right to a second expert opinion shall entitle the operator to request a documentary review of the sampling, analysis, test or diagnosis by another recognised and appropriately qualified expert. 3. Member States may decide that, where there is a dispute between the competent authorities and the operators that is based on the second expert opinion referred to in paragraph 1, the operators may request, at their own expense, the documentary review of the initial analysis, test or diagnosis and, where appropriate, another analysis, test or diagnosis by another official laboratory. second expert How did you organise this issue in your country? 16 Food safety

Right to a second opinion in case of non-compliance Four approaches can be identified within the Member States if the enforcement sample generates a non-compliant result 1. the consignment is considered compliant and released (the result of the defence samples supersedes the outcome of the official result). This approach is followed in France, Greece, Sweden, Belgium, and Finland 2. the reference sample is analysed in the national reference laboratory. If the analytical result is compliant with the legislation, the consignment is considered compliant and released. This approach is followed in UK, Estonia, Hungary, Spain, Poland, Czech Republic, The Netherlands, Portugal, Ireland, Slovak Republic, Romania, Italy, and Latvia 17 Food safety

Right of second opinion in case of non-compliance 3. the operator must challenge the analytical result of the official sample before a Court. This approach is followed in Denmark, Slovenia, Germany, Luxembourg, and Lithuania 4. the operator must demonstrate that the consignment is compliant by organising at least an additional sampling of the lot and an analysis of these samples by an accredited laboratory, associated with an expert approved by the competent authority to carry out expertise on such samples taken during official controls. If the analytical result is compliant with the legislation, the rest of the consignment is considered compliant and released. This approach is followed in Austria. 18 Food safety

This presentation has been produced under the contract with the Consumers, Health, Agriculture and Food Executive Agency (CHAFEA). The content of this page is the sole responsibility of NSF Euro Consultants Consortium and can in no way be taken to reflect the views of the Consumers, Health, Agriculture and Food Executive Agency or any other body of the European Union. The Consumers, Health, Agriculture and Food Executive Agency or any other body of the European Union will not be responsible under any circumstances for the contents of communication items prepared by the contractors. NSF Euro Consultants Consortium Thank you for your attention! Any questions? Avenue Pasteur,21 1300 Wavre Belgium +32 10 84 97 95 2016.96.05@euroconsultants.be Better Training for Safer Food BTSF European Commission Consumers, Health, Agriculture and Food Executive Agency DRB A3/042 L-2920 Luxembourg Food safety