Combined Effect of Magnetic Fluids and Variable Viscosity on Lubrication of Finite Journal Bearings

Study investigating the impact of magnetic fluids, couple stresses, variable viscosity, and velocity slip on the lubrication of finite journal bearings. The research focuses on pressure distribution, load-carrying capacity, and frictional coefficient in the context of tribology.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

The Combined Effect of Magnetic Fluids with Couple Stresses, Variable Viscosity and Velocity-Slip on the Lubrication of Finite Journal Bearings. Tyrone D. Dass1, Sreedhara Rao Gunakala2 and Donna M.G. Comissiong3 1Foundations and Prior Learning, University of Trinidad and Tobago, 2,3Department of Mathematics and Statistics, the University of the West Indies, St. Augustine. IConETech-2020, Faculty of Engineering, The UWI, St. Augustine, Trinidad and Tobago 1

INTRODUCTION TRIBOS IConETech-2020, Faculty of Engineering, The UWI, St. Augustine, Trinidad and Tobago 2

INTRODUCTION Scheme of the Bearing IConETech-2020, Faculty of Engineering, The UWI, St. Augustine, Trinidad and Tobago 3

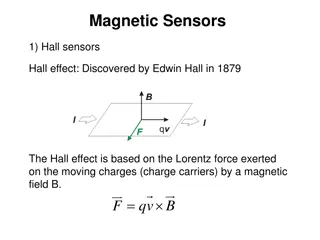

INTRODUCTION The displaced infinitely long wire magnetic field model K:- the distance of the magnetic field over the radius of the bearing Current IConETech-2020, Faculty of Engineering, The UWI, St. Augustine, Trinidad and Tobago 4

INTRODUCTION Magnetic Fluid (Ferro-fluid) IConETech-2020, Faculty of Engineering, The UWI, St. Augustine, Trinidad and Tobago 5

OBJECTIVES We study the Combined Effect of the following: Magnetic Fluid (ferrofluid) Couple-stress Velocity-slip Variable viscosity On Pressure Distribution Load Carrying Capacity Frictional Coefficient In the Lubrication of the finite Journal Bearing IConETech-2020, Faculty of Engineering, The UWI, St. Augustine, Trinidad and Tobago 6

METHODOLOGY Governing Equations 1 2 u du dt = + + + 2 . P F C u u m = + 4 2 . u p F mx Boundary Conditions = = = , 0, at u U u z h = = = an d 0 at 0 u u u z zz z zz IConETech-2020, Faculty of Engineering, The UWI, St. Augustine, Trinidad and Tobago 7

METHODOLOGY Velocity in the x-direction p p e U e e dp dx = + u U z F mx + p 0 0 + h 0 0.5 p p e e 2 p 2 2 h h le tanh h 2 l + 0 2 z z p e + h 0 ( ) 2 z h p cosh e 2 l h p e dp dx 2 p 2 1 F l e mx 0.5 p cosh e 0 2 l IConETech-2020, Faculty of Engineering, The UWI, St. Augustine, Trinidad and Tobago 8

METHODOLOGY Modified Reynolds Equation and the Load Carrying Capacity + + p 3 3 p p 2 e h dp dx h e Uh h e ( ) ( ) , , , , h l = + , , , , h l 0 . f p f p F 2 2 mx p 2 2 2 x x x e h 0 0 0 1/2 2 e A He e A H e + + + 1 1 cos H H d ( ) ( ) 2 + + A A 3 * 3 * , , , H l , , , H l H F A H F A 2 0 2 2 = * W 2 e A He e A H e + + 1 1 sin H H d ( ) ( ) 2 + + A A 3 * 3 * , , , H l , , , H l H F A H F A 2 0 2 2 ( ) = * * / / R C F W Frictional Parameter f 0..5 e 2 tanh e H H l e H 2 l 2 1 e H e A He e A H e = + + d d 1 1 F H H ( ) ( ) ( ) 2 + + + + A A A 3 3 2 A e H , , , H l , , , H l H F A H F A 2 0 2 2 IConETech-2020, Faculty of Engineering, The UWI, St. Augustine, Trinidad and Tobago 9

RESULTS Tables should have a minimum text size of 20pt. Highest P Occurs Increased l and The title of each table should be centred and placed above the table. Table Title Heading 2 Heading 3 Heading 4 Heading 1 IConETech-2020, Faculty of Engineering, The UWI, St. Augustine, Trinidad and Tobago 10

RESULTS Table 1(Pressure vs. Circumferential Coordinate ) Piezo-Viscosity Parameter Maximum Magnetic Pressure 90.63 = Maximum Hydrodynamic Pressure 151.9 = 0.00 36.71 46.80 0.10 37.10 47.50 0.20 37.54 48.27 0.30 38.02 49.11 0.35 38.80 49.56 IConETech-2020, Faculty of Engineering, The UWI, St. Augustine, Trinidad and Tobago 11

RESULTS Load increases with l Load greater in the presence of magnetic parameter Load increases with piezo- viscosity parameter LOAD VS. COUPLE-STRESS IConETech-2020, Faculty of Engineering, The UWI, St. Augustine, Trinidad and Tobago 12

RESULTS W decreases with increasing Slip-parameter A W increases with Increasing couple- Stress parameter W increases with Increasing magnetic parameter LOAD VS. SLIP-PARAMETER IConETech-2020, Faculty of Engineering, The UWI, St. Augustine, Trinidad and Tobago 13

RESULTS W increases with increasing and Decreases with Increasing K 1 LOAD VS. DISTANCE RATIO IConETech-2020, Faculty of Engineering, The UWI, St. Augustine, Trinidad and Tobago 14

RESULTS FRICTION VS Distance Ratio FRICTION VS COUPLE-STRESS IConETech-2020, Faculty of Engineering, The UWI, St. Augustine, Trinidad and Tobago 15

RESULTS Large A Implies No-slip condition. Small A Implies Slip- condition FRICTION VS SLIP-PARAMETER IConETech-2020, Faculty of Engineering, The UWI, St. Augustine, Trinidad and Tobago 16

CONCLUSION The maximum magnetic and HD pressures increase with increasing piezo-viscosity parameter in the presence of the slip parameter. Higher load values occur in the presence of the magnetic parameter, high eccentricity ratio, and higher piezo-viscosity parameter. For an increase in the magnetic parameter the friction decreases. The combined effect of high couple-stress parameter and low piezo- viscosity parameter yields the lowest friction. From the above results, we can enhance the journal bearing parameters by combining the slip, piezo-viscosity, and couple-stress parameters. Application: One application would involve the reduction of start-up friction. The magnetic-fluid may be retained at any desired position, and metal to metal contact will be avoided without the need of any external lubrication. IConETech-2020, Faculty of Engineering, The UWI, St. Augustine, Trinidad and Tobago 17

REFERENCES Tipei, Nicolae. 1983. Overall Characteristics of Bearings Lubricated With Ferrofluids. Journal of Lubrication Technology, Vol. 105. Transactions of the ASME. Agrawal, V.K. 1986. Magnetic-fluid based porous inclined slider bearing. Wear, Vol. 107, (pp. 133-139). S. Verma and K. Budheeja. 2012. Study of Piezo-Viscous Effect on Multirecessed Capillary Compensated Hydrostatic Journal Bearing. ResearchGate, National Conference on Advancements in Mechanical Engineering and Energy environment, SLIET, Longowal, (Pb) India, 6-7. N. S. Patel, D. P. Vakharia, and G. M. Deheri. 2012. A Study on the Performance of a Magnetic-Fluid-Based Hydrodynamic Short Journal Bearing. International Scholarly Research Network ISRN Mechanical Engineering .Article ID 603460, doi:10.5402/2012/603460. Jaw-Ren Lin, Po-Jui Li, and Tzu-Chen Hung. 2013. Effects of Non-Newtonian Ferrofluids on the Performance Characteristics of Long Journal Bearings. FDMP, vol. 9, no.4 (pp.419-434). IConETech-2020, Faculty of Engineering, The UWI, St. Augustine, Trinidad and Tobago 18

THANK YOU! IConETech-2020, Faculty of Engineering, The UWI, St. Augustine, Trinidad and Tobago 19