Caterpillar Cat D6K2 XL TRACK-TYPE TRACTOR (Prefix DFR) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn// n

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

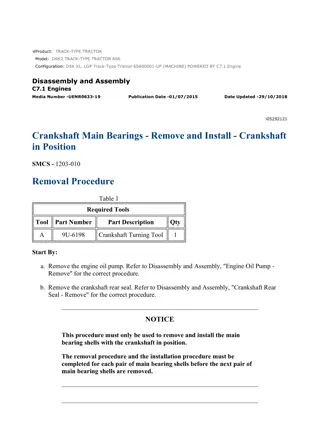

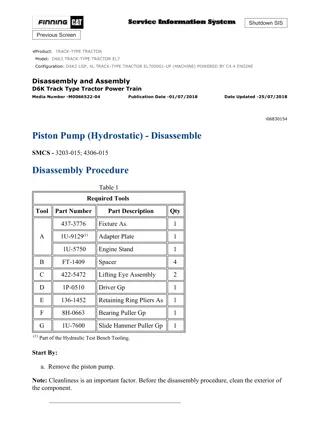

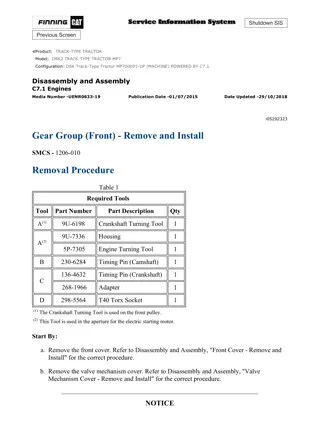

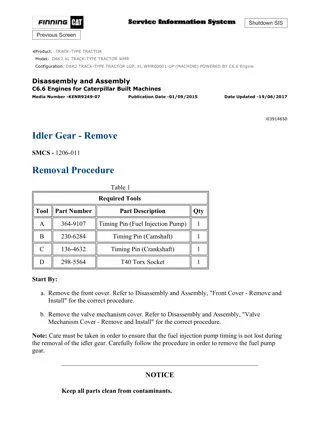

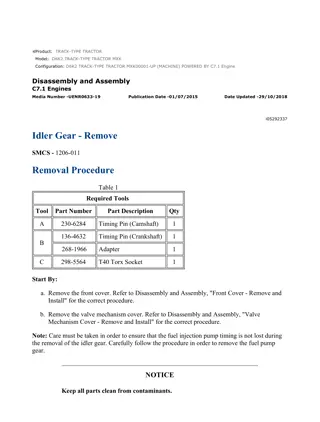

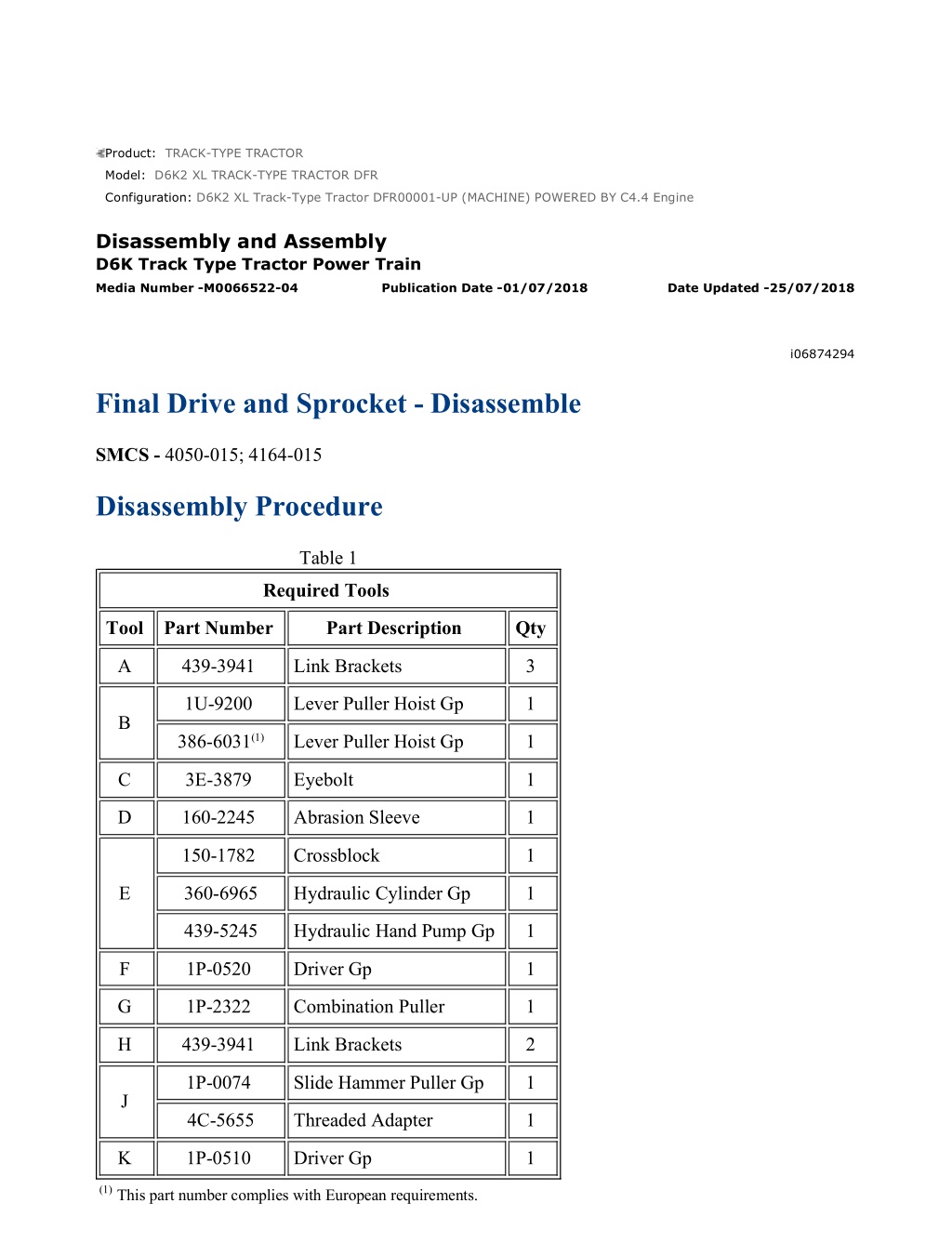

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 1/11 Product: TRACK-TYPE TRACTOR Model: D6K2 XL TRACK-TYPE TRACTOR DFR Configuration: D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Engine Disassembly and Assembly D6K Track Type Tractor Power Train Media Number -M0066522-04 Publication Date -01/07/2018 Date Updated -25/07/2018 i06874294 Final Drive and Sprocket - Disassemble SMCS - 4050-015; 4164-015 Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 439-3941 Link Brackets 3 1U-9200 Lever Puller Hoist Gp 1 B 386-6031(1) Lever Puller Hoist Gp 1 C 3E-3879 Eyebolt 1 D 160-2245 Abrasion Sleeve 1 150-1782 Crossblock 1 E 360-6965 Hydraulic Cylinder Gp 1 439-5245 Hydraulic Hand Pump Gp 1 F 1P-0520 Driver Gp 1 G 1P-2322 Combination Puller 1 H 439-3941 Link Brackets 2 1P-0074 Slide Hammer Puller Gp 1 J 4C-5655 Threaded Adapter 1 K 1P-0510 Driver Gp 1 (1)This part number complies with European requirements. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 2/11 Start By: a. Remove the final drive and brake. b. Remove the track brake. When you are using hydraulic cylinders and puller studs, always ensure that the rated capacity of the puller stud meets or exceeds the rated capacity of the hydraulic cylinder. If the puller stud does not meet or exceed the rated capacity of the hydraulic cylinder, a sudden failure of the puller stud could occur. The sudden failure of the puller stud could result in personal injury or death. 1. Drain the final drive oil. Refer to Operation and Maintenance Manual, "Final Drive Oil - Change" for the correct draining procedure. Illustration 1 g03039906 2. Attach Tooling (A), Tooling (B), and a suitable lifting device to final drive (1). The weight of final drive (1) is approximately 590 kg (1300 lb). Position final drive (1) onto suitable cribbing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 3/11 Illustration 2 g03039916 3. Remove bolts (2), cover (1), and the O-ring seal. Illustration 3 g03040636 4. Use Tooling (C) to remove sun gear shaft assembly (4). Illustration 4 g03041498 5. Attach Tooling (D) and a suitable lifting device to planetary assembly (6). The weight of planetary assembly (6) is approximately 109 kg (240 lb). Remove bolts (5) and planetary assembly (6). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 4/11 Illustration 5 g03041719 6. Remove O-ring seal (11). 7. Remove bolt (7), washer (8), retainer (9), and O-ring seal (10). Repeat for the remaining planetary gears. Illustration 6 g03041721 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 5/11 Illustration 7 g03041776 8. Use a suitable press to remove shaft (12). Remove shaft (12), bearing cone (13), planetary gear (15), and bearing cone (17) from the planetary carrier. Remove bearing cup (14) and bearing cup (16) from planetary gear (15). Repeat for the remaining planetary gears. Illustration 8 g03042099 9. Attach Tooling (D) and a suitable lifting device to ring gear (18) and hub (19). The combined weight of ring gear (18) and hub (19) is approximately 40 kg (88 lb). Remove bolts (20) and retainer plate (21). Remove ring gear (18) and hub (19) as a unit. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 6/11 Illustration 9 g03042177 10. Attach Tooling (D) and a suitable lifting device to hub (19). The weight of hub (19) is approximately 18 kg (40 lb). Remove retaining ring (22). Remove hub (19) from ring gear (18). Illustration 10 g03042296 11. Attach Tooling (E) and Tooling (F) to separate bearing cone (23) and sprocket hub (24). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 7/11 Illustration 11 g03043624 12. Remove bearing cone (23). 13. Attach Tooling (A) and a suitable lifting device to sprocket hub (24). The combined weight of sprocket hub (24) and the sprocket segments is approximately 186 kg (410 lb). Remove sprocket hub (24) and the sprocket segments as a unit. Illustration 12 g03043818 14. Remove Duo-Cone seal (25) and bearing cups (26) from sprocket hub (24). Refer to Special Instruction, SEHS8364, "Assembly and Installation of Conventional Duo-Cone Seals" for installation instructions. Illustration 13 g03043819 15. Remove Duo-Cone seal (27). Refer to Special Instruction, SEHS8364, "Assembly and Installation of Conventional Duo-Cone Seals" for installation instructions. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 8/11 Illustration 14 g03043837 Illustration 15 g03043839 16. Use Tooling (G) and Tooling (F) to remove bearing cone (28). 17. Attach Tooling (H) and a suitable lifting device to spindle (30). The weight of spindle (30) is approximately 127 kg (280 lb). Remove bolts (29), spindle (30), and O-ring seal (32). 18. Remove bearing outer race (31) from spindle (30). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 9/11 Illustration 16 g03043841 19. Remove bull gear (33). Illustration 17 g03043842 20. Use Tooling (G) and Tooling (F) to remove inner bearing (34) from bull gear (33). Illustration 18 g03043844 21. Remove thrust button (35). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 E... 10/11 Illustration 19 g03043896 22. Attach Tooling (A) and a suitable lifting device to final drive case (36). The weight of final drive case (36) is approximately 75 kg (165 lb). Position final drive case (36) as shown. Illustration 20 g03043898 23. Remove bolts (38) and retainer (37). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 E... 11/11 Illustration 21 g03043900 24. Use Tooling (J) to remove gear assembly (39) and bearing cup (40). Illustration 22 g03043901 25. Use Tooling (G) and Tooling (K) to remove bearing cones (41). Illustration 23 g03043902 26. Remove bearing cup (42). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

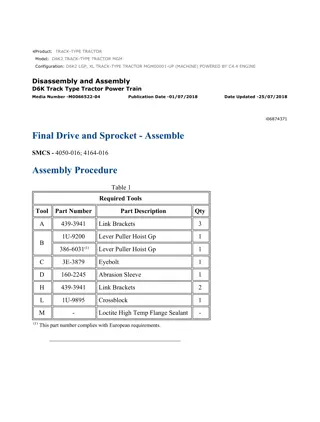

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 1/11 Product: TRACK-TYPE TRACTOR Model: D6K2 XL TRACK-TYPE TRACTOR DFR Configuration: D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Engine Disassembly and Assembly D6K Track Type Tractor Power Train Media Number -M0066522-04 Publication Date -01/07/2018 Date Updated -25/07/2018 i06874371 Final Drive and Sprocket - Assemble SMCS - 4050-016; 4164-016 Assembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 439-3941 Link Brackets 3 1U-9200 Lever Puller Hoist Gp 1 B 386-6031(1) Lever Puller Hoist Gp 1 C 3E-3879 Eyebolt 1 D 160-2245 Abrasion Sleeve 1 H 439-3941 Link Brackets 2 L 1U-9895 Crossblock 1 M - Loctite High Temp Flange Sealant - (1)This part number complies with European requirements. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 2/11 Illustration 1 g03043902 1. Lower the temperature of bearing cup (42) and install bearing cup (42). Illustration 2 g03043903 2. Raise the temperature of bearing cones (41) and install bearing cones (41). Lubricate bearing cones (41) with SAE 30 oil. Positively seat the bearing cones against the locating shoulders of the gear assembly after the bearing cones have cooled. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 3/11 Illustration 3 g03043904 3. Install gear assembly (39). 4. Lower the temperature of bearing cup (40) and install bearing cup (40). 5. Install retainer (37) and bolts (38). Illustration 4 g03043896 6. Attach Tooling (A) and a suitable lifting device to final drive case (36). The weight of final drive case (36) is approximately 75 kg (165 lb). Reposition final drive case (36). Illustration 5 g03043844 7. Apply Tooling (M) to the mating surface of thrust button (35) and the final drive case. Install thrust button (35). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 4/11 Illustration 6 g03044959 8. Raise the temperature of inner bearing (34) and install inner bearing (34) onto bull gear (33). 9. Install bull gear (33). Illustration 7 g03043839 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 5/11 Illustration 8 g03044996 10. Lower the temperature of bearing outer race (31) and install bearing outer race (31) into spindle (30). 11. Attach Tooling (H) and a suitable lifting device to spindle (30). The weight of spindle (30) is approximately 127 kg (280 lb). Install O-ring seal (32), spindle (30), and bolts (29). Lubricate O-ring seal (32) with the lubricant that is being sealed. 12. Raise the temperature of bearing cone (28) and install bearing cone (28). Lubricate bearing cone (28) with SAE 30 oil. 13. Install Duo-Cone seal (27). Refer to Special Instruction, SEHS8364, "Assembly and Installation of Conventional Duo-Cone Seals" for installation instructions. Illustration 9 g03043818 14. Lower the temperature of bearing cups (26) and install bearing cups (26) into sprocket hub (24). 15. Install Duo-Cone seal (25). Refer to Special Instruction, SEHS8364, "Assembly and Installation of Conventional Duo-Cone Seals" for installation instructions. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 6/11 Illustration 10 g03043624 16. Attach Tooling (A) and a suitable lifting device to sprocket hub (24). The combined weight of sprocket hub (24) and the sprocket segments is approximately 186 kg (410 lb). Install sprocket hub (24) and the sprocket segments as a unit. 17. Raise the temperature of bearing cone (23) and install bearing cone (23). Lubricate bearing cone (23) with SAE 30 oil. Illustration 11 g03042177 18. Attach Tooling (D) and a suitable lifting device to hub (19). The weight of hub (19) is approximately 18 kg (40 lb). Install hub (19) into ring gear (18). Install retaining ring (22). Illustration 12 g03045047 19. Attach Tooling (D) and a suitable lifting device to ring gear (18) and hub (19). The combined weight of ring gear (18) and hub (19) is approximately 40 kg (88 lb). Install ring gear (18) and hub (19) as a unit. Install retainer plate (21) and three bolts (20) equally spaced. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 7/11 Illustration 13 g03045048 20. Use Tooling (L) and a suitable press to seat the bearing cones. Use the suitable press to apply an axial load of 120 10 kN (26977 2248 lb). Rotate sprocket hub (24). Tighten three bolts (20) to a torque of 95 10 N m (70 7 lb ft). 21. Remove Tooling (L) and the suitable press. Illustration 14 g03045049 22. Install the remaining bolts (20). Tighten bolts (20) to a torque of 120 20 N m (89 15 lb ft). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 8/11 Illustration 15 g03041776 Illustration 16 g03045118 23. Lower the temperature of bearing cup (14) and bearing cup (16). Install bearing cup (14) and bearing cup (16) into planetary gear (15). Lubricate bearing cone (13) and bearing cone (17) with SAE 30 oil. Install bearing cone (13), planetary gear (15), and bearing cone (17) into the planetary carrier. Use a suitable press to install shaft (12). Repeat for the remaining planetary gears. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 9/11 Illustration 17 g03041719 24. Install O-ring seal (11). Lubricate O-ring seal (11) with the lubricant that is being sealed. 25. Install O-ring seal (10), retainer (9), washer (8), and bolt (7). Repeat for the remaining planetary gears. Illustration 18 g03041498 26. Attach Tooling (D) and a suitable lifting device to planetary assembly (6). The weight of planetary assembly (6) is approximately 109 kg (240 lb). Install planetary assembly (6) and bolts (5). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 E... 10/11 Illustration 19 g03040636 27. Use Tooling (C) to install sun gear shaft assembly (4). Illustration 20 g03039916 28. Install the O-ring seal, cover (1), and bolts (2). Illustration 21 g03039906 29. Attach Tooling (A), Tooling (B), and a suitable lifting device to final drive (1). The weight of final drive (1) is approximately 590 kg (1300 lb). Position final drive (1) onto suitable cribbing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 E... 11/11 30. Fill the final drive oil. Refer to Operation and Maintenance Manual, "Final Drive Oil - Change" for the correct filling procedure. End By: a. Install the track brake. b. Install the final drive and brake. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 1/4 Product: TRACK-TYPE TRACTOR Model: D6K2 XL TRACK-TYPE TRACTOR DFR Configuration: D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Engine Disassembly and Assembly D6K Track Type Tractor Power Train Media Number -M0066522-04 Publication Date -01/07/2018 Date Updated -25/07/2018 i06667208 Final Drive and Brake - Remove and Install SMCS - 4050-010; 4131-010; 4251-010 Removal Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1U-7498 Support Stand As 2 B 310-3992 Guide Studs 2 C 1U-9200 Lever Puller Hoist Gp 1 Illustration 1 g03019258 1. Position the machine on suitable cribbing, as shown. Position the master link on the final drive, as shown. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 2/4 Illustration 2 g03019259 2. Position bulldozer blade (1) onto Tooling (A). 3. Separate the track. 4. Release system pressure. 5. Remove the track drive motor. Illustration 3 g03019260 6. Remove two bolts (2). Illustration 4 g03019276 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 3/4 Illustration 5 g03019278 Illustration 6 g03019277 7. Install Tooling (B). 8. Disconnect hose assembly (4). 9. Attach a suitable lifting device to final drive and parking brake (3). The weight of final drive and parking brake (3) is approximately 590 kg (1300 lb). 10. Remove bolts (5) and bolts (2). Reposition final drive and parking brake (3) on Tooling (B). Attach Tooling (C) and another suitable lifting device to final drive and parking brake (3). Remove final drive and parking brake (3). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 4/4 Illustration 7 g03039903 11. Position final drive and parking brake (3) onto suitable cribbing. Use the suitable cribbing to support final drive and parking brake (3). Installation Procedure 1. Install final drive and parking brake (3) in the reverse order of removal. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 1/6 Product: TRACK-TYPE TRACTOR Model: D6K2 XL TRACK-TYPE TRACTOR DFR Configuration: D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Engine Disassembly and Assembly D6K Track Type Tractor Power Train Media Number -M0066522-04 Publication Date -01/07/2018 Date Updated -25/07/2018 i06567407 Piston Pump (Hydrostatic) - Remove and Install SMCS - 3203-010; 4306-010; 5070-010-H7 Removal Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1U-7505 Hydraulic Jack 1 B 439-3938 Link Bracket 2 Start By: a. Remove Piston Pump (Winch). b. Remove Piston Pump (Implement) Illustration 1 g06029295 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 2/6 1. Remove bolts (2) and cover (1). Illustration 2 g06029309 2. Remove cable straps holding hoses (3). Position hoses (3) out of the way. Remove bolts (4) and disconnect hose assemblies (6). Illustration 3 g06029340 3. Remove cable straps (10) and disconnect harness assemblies (7). Remove cable straps (9) and disconnect hose assembly (8). Illustration 4 g06029354 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

D6K2 XL Track-Type Tractor DFR00001-UP (MACHINE) POWERED BY C4.4 Eng... 3/6 4. Disconnect hose assemblies (11). Remove cable strap (13) and disconnect harness assemblies (12). Illustration 5 g06029361 5. Disconnect harness assemblies (14) from pressure sensors (16). Disconnect hose assemblies (15). Illustration 6 g06029369 6. Remove clip (17) and cable straps (18) and disconnect harness assembly (19) Illustration 7 g06029376 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/12/20

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com