Caterpillar Cat D6K2 TRACK-TYPE TRACTOR (Prefix EL7) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

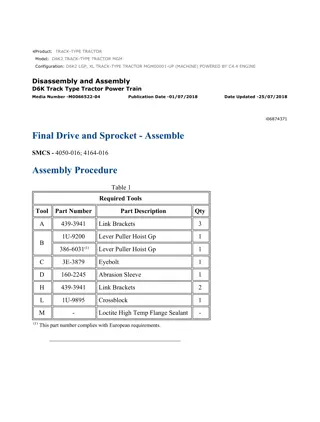

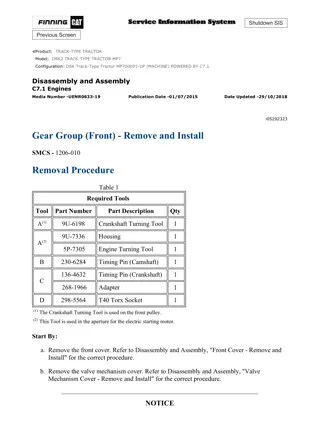

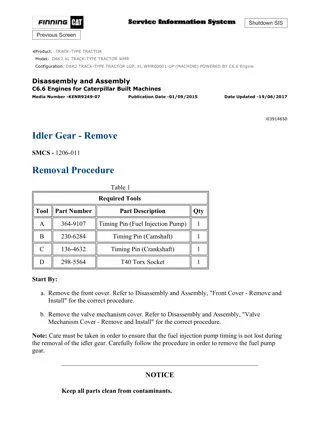

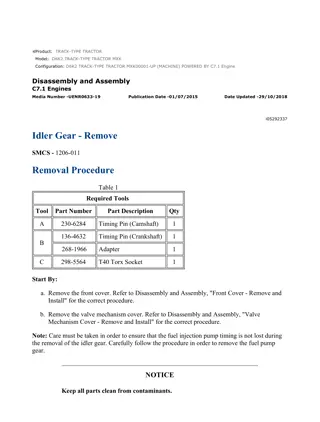

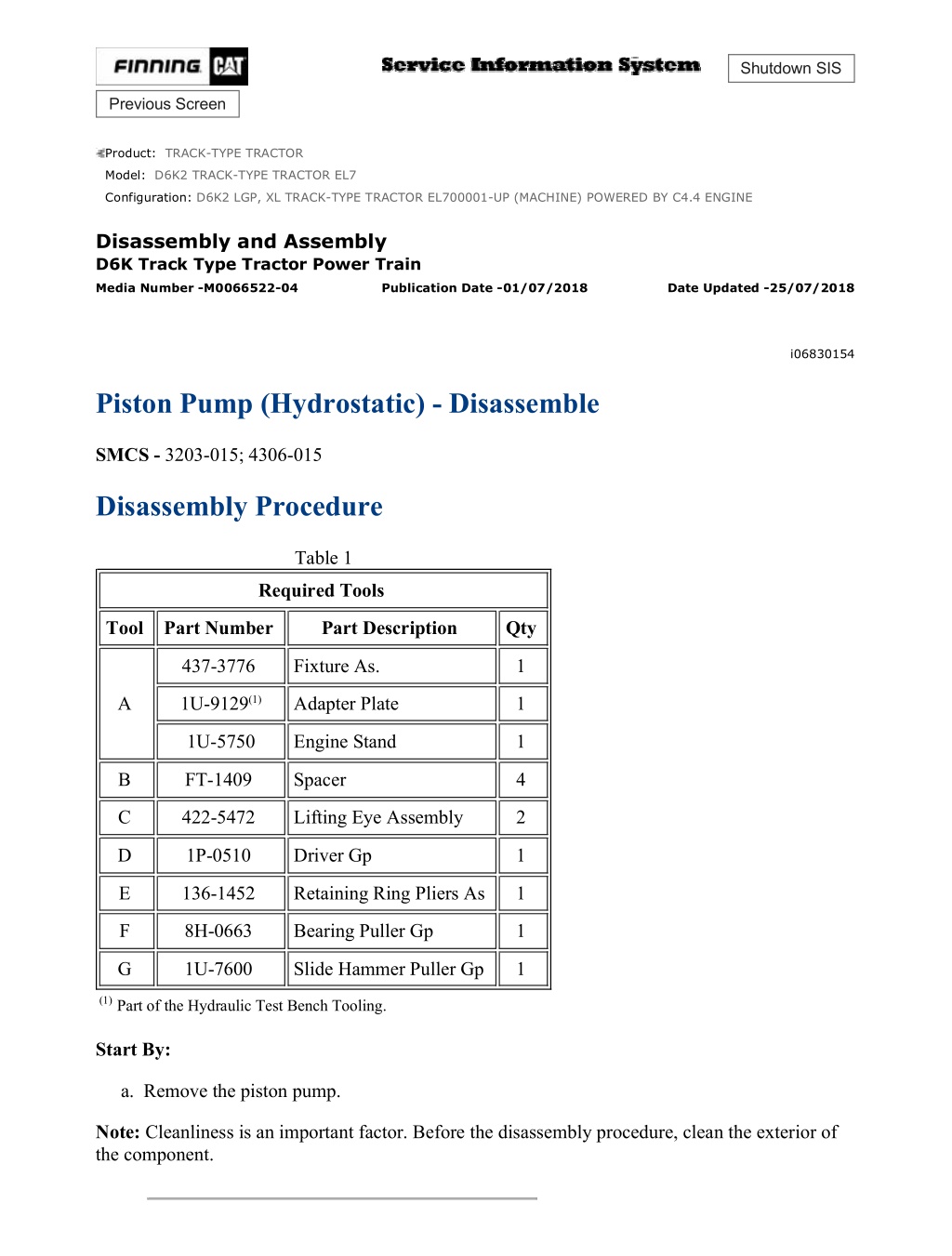

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERED ... 1/18 Shutdown SIS Previous Screen Product: TRACK-TYPE TRACTOR Model: D6K2 TRACK-TYPE TRACTOR EL7 Configuration: D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERED BY C4.4 ENGINE Disassembly and Assembly D6K Track Type Tractor Power Train Media Number -M0066522-04 Publication Date -01/07/2018 Date Updated -25/07/2018 i06830154 Piston Pump (Hydrostatic) - Disassemble SMCS - 3203-015; 4306-015 Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty 437-3776 Fixture As. 1 A 1U-9129(1) Adapter Plate 1 1U-5750 Engine Stand 1 B FT-1409 Spacer 4 C 422-5472 Lifting Eye Assembly 2 D 1P-0510 Driver Gp 1 E 136-1452 Retaining Ring Pliers As 1 F 8H-0663 Bearing Puller Gp 1 G 1U-7600 Slide Hammer Puller Gp 1 (1)Part of the Hydraulic Test Bench Tooling. Start By: a. Remove the piston pump. Note: Cleanliness is an important factor. Before the disassembly procedure, clean the exterior of the component. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERED ... 2/18 Illustration 1 g06133100 Illustration 2 g06133092 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 1. Use Tooling (B) to secure the piston pump to Tooling (A) or a suitable fixture. 2. Attach Tooling (C) and a suitable lifting device to pump housing (1). Remove bolts (2) and pump housing (1). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERED ... 3/18 Illustration 3 g06133924 3. Remove port plate (3) from pump housing (1). Illustration 4 g06133926 4. Remove O-ring seal (5). Use nylon string to remove rotating assembly (4). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERED ... 4/18 Illustration 5 g06133950 5. Remove piston assemblies (6) and retainer plate (7) from barrel assembly (8). Illustration 6 g06133954 6. Remove ball joint (9) from barrel assembly (8). Illustration 7 g06134090 7. Remove shim (10) and spring assembly (11) from barrel assembly (8). Illustration 8 g06134094 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERED ... 5/18 Illustration 9 g06134096 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 8. Use Tooling (D) and a suitable press to compress spring (14). Remove retaining ring (12). 9. Remove washers (13) and spring (14) from barrel assembly (8). Illustration 10 g06134099 Note: Note the orientation of slide (16) for assembly purposes. 10. Remove swashplate assembly (15). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERED ... 6/18 Illustration 11 g06134102 11. Remove slide (16) and bearing assemblies (17) from swashplate assembly (15). Illustration 12 g06134104 12. Remove bearing liners (18). Illustration 13 g06134105 13. Use Tooling (E) to remove retaining ring (19) from front mounting flange (21). 14. Use Tooling (G) to remove lip seal (20) from front mounting flange (21). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERED ... 7/18 Illustration 14 g06134136 15. Use Tooling (E) to remove retaining ring (22) from front mounting flange (21). Illustration 15 g06134179 16. Use a suitable press to remove shaft (23) from front mounting flange (21). Illustration 16 g06134180 17. Remove retaining ring (24). Use Tooling (F) and a suitable press to remove bearing (25) from shaft (23). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERED ... 8/18 Illustration 17 g06134183 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 18. Reattach pump housing (1) to Tooling (A) with rear mounting flange assembly (27) facing down. 19. Remove bolts (26). Use a suitable lifting device to remove pump housing (1) from rear mounting flange assembly (27). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERED ... 9/18 Illustration 18 g06134236 20. Remove port plate (28) from pump housing (1). Illustration 19 g06134249 21. Remove O-ring seal (30). Use a nylon string to remove rotating assembly (29). Illustration 20 g06134254 22. Remove piston assemblies (31) and retainer plate (32) from barrel assembly (33). Illustration 21 g06134258 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERE... 10/18 23. Remove ball joint (34) from barrel assembly (33). Illustration 22 g06134262 24. Remove shim (35) and spring assembly (36) from barrel assembly (33). Illustration 23 g06134265 Illustration 24 g06134268 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERE... 11/18 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 25. Use Tooling (D) and a suitable press to compress spring (39). Remove retaining ring (37). 26. Remove washers (38) and spring (39) from barrel assembly (33). Illustration 25 g06134276 Note: Note the orientation of slide (41) for assembly purposes. 27. Remove swashplate assembly (40). Illustration 26 g06134480 28. Remove bearing liners (42). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERE... 12/18 Illustration 27 g06134580 29. Remove bolts (44) and rear mounting flange (43) from rear mounting flange assembly (27). 30. Remove plate (45) and the O-ring seal. Illustration 28 g06134589 31. Remove plate (46) and O-ring seal (48) from rear mounting flange assembly (27). Use Tooling (E) to remove retaining ring (47). Illustration 29 g06134598 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERE... 13/18 32. Use a suitable press to remove shaft assembly (49) from rear mounting flange assembly (27). Illustration 30 g06134633 33. Remove retaining ring (50). Use Tooling (F) and a suitable press to remove bearing (50) from shaft assembly (49). Illustration 31 g06134643 34. Remove plugs (51) and the O-ring seals from pump housing (1). Illustration 32 g06135182 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERE... 14/18 35. Remove valve assemblies (55). Remove bolts (52), cap (53), and O-ring seal (54) from the pump housing. Repeat for the opposite side. Illustration 33 g06134898 36. Remove O-ring seal (56) from valve assembly (55). Repeat for other valves. Illustration 34 g06134900 37. Remove solenoid assemblies (57) from pump housing (1). Illustration 35 g06134903 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERE... 15/18 38. Remove nuts (58), O-ring seals (59), coil assemblies (60), cartridges (61), and O-ring seals (62). Illustration 36 g06134909 Illustration 37 g06134912 39. Remove plugs (63) and the O-ring seals. Remove bolts (65), cover (66), and valve group (64) from the pump housing. Remove gasket (67). Repeat for the opposite side. Illustration 38 g06134925 40. Remove nuts (68), O-ring seals (69), coil assemblies (70), cartridges (71), and O-ring seals (72) from control block (64). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERE... 16/18 Illustration 39 g06134931 41. Remove bolt (73), retainer (74), and eccentric pin (75) from control block (64). Illustration 40 g06134936 42. Remove O-ring seal (76) and spring (77) from eccentric pin (75). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERE... 17/18 Illustration 41 g06134940 43. Remove levers (78), spring (79), washer (80), reaction arm (81), and spool (82) from control block (64). Repeat for opposite side. Illustration 42 g06135001 Illustration 43 g06134994 44. Remove nut (84) and bolts (83) from cover (85). 45. Use a soft faced hammer to tap adjustment screw (86) from the back side of the pump housing until the O-ring seal on cover (85) clears the pump housing. 46. Unscrew cover (86) from adjustment screw (86). Note: Count the number of revolutions required for removal for installation purposes. 47. Remove control piston (86) from pump housing (1). Repeat for opposite side. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERE... 18/18 Illustration 44 g06135008 48. Remove ring (87) and guide ring (88) from pump housing (1). Copyright 1993 - 2021 Caterpillar Inc. Tue Aug 31 08:13:26 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERED ... 1/18 Shutdown SIS Previous Screen Product: TRACK-TYPE TRACTOR Model: D6K2 TRACK-TYPE TRACTOR EL7 Configuration: D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERED BY C4.4 ENGINE Disassembly and Assembly D6K Track Type Tractor Power Train Media Number -M0066522-04 Publication Date -01/07/2018 Date Updated -25/07/2018 i06830157 Piston Pump (Hydrostatic) - Assemble SMCS - 3203-016; 4306-016 Assembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty 437-3776 Fixture As. 1 A 1U-9129(1) Adapter Plate 1 1U-5750 Engine Stand 1 B FT-1409 Spacer 4 C 422-5472 Lifting Eye Assembly 2 D 1P-0510 Driver Gp 1 E 136-1452 Retaining Ring Pliers As 1 F 8H-0663 Bearing Puller Gp 1 G 1U-7600 Slide Hammer Puller Gp 1 H 6V-2055 Grease 1 (1)Part of the Hydraulic Test Bench Tooling. Note: Cleanliness is an important factor. Before assembly, thoroughly clean all parts in cleaning fluid. Allow the parts to air dry. Do not use wiping cloths or rags to dry parts. Lint may be deposited on the parts which may cause trouble. Inspect all parts. If any parts are worn or damaged, use new parts for replacement. Dirt and other contaminants can damage the precision component. Perform assembly procedures on a clean work surface. Always keep components covered and protected . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERED ... 2/18 Note: Check the O-ring seals, the gaskets, and the seals for wear or for damage. Replace the components, if necessary. Illustration 1 g06135231 1. Install guide ring (88) and ring (87) into pump housing (1). Repeat for the opposite side. Illustration 2 g06135233 Illustration 3 g06135235 2. Install control piston (87) into pump housing (1). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERED ... 3/18 3. Install the O-ring seal and cover (85) onto adjustment screw (86). Note: Install cover (85) to a depth of 22 revolutions if original depth is unknown. 4. Install bolts (83) onto cover (85). Tighten bolts (83) to a torque of 130 13 N m (95 10 lb ft). 5. Install nut (84) onto adjustment screw (86). Tighten nut (84) to a torque of 180 18 N m (133 13 lb ft). Repeat for opposite side. Illustration 4 g06134940 6. Install spool (82), reaction arm (81), washer (80), spring (79), and levers (78) into control block (64). Repeat for opposite side. Illustration 5 g06134936 7. Install spring (77) and O-ring seal (78) onto eccentric pin (75). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERED ... 4/18 Illustration 6 g06134931 8. Install eccentric pin (75), retainer (74), and bolt (73) into control block (64). Illustration 7 g06134925 9. Install O-ring seals (72), cartridges (71), coil assemblies (70), O-ring seals (69), and nuts (68) from control block (64). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERED ... 5/18 Illustration 8 g06134912 Illustration 9 g06134909 10. Install gasket (67). Install valve group (64), cover (66), bolts (65), plugs (63), and the O-ring seals onto the pump housing. Tighten bolts (65) to a torque of 15.5 2 N m (137 18 lb in). Repeat for the opposite side. Illustration 10 g06134903 11. Install O-ring seals (62), cartridges (61), coil assemblies (60), O-ring seals (59), and nuts (58). Illustration 11 g06134900 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERED ... 6/18 12. Install solenoid assemblies (57) into pump housing (1). Illustration 12 g06134898 13. Install O-ring seal (56) onto valve assembly (55). Repeat for other valves. Illustration 13 g06135182 14. Install O-ring seal (54), cap (53), and bolts (52) into the pump housing. Tighten bolts (52) to a torque of 130 13 N m (96 10 lb ft). Install valves (55). Tighten valves (55) to a torque of 250 N m (184 lb ft). Repeat for the opposite side. Illustration 14 g06134643 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERED ... 7/18 15. Install plugs (51) and the O-ring seals into pump housing (1). Illustration 15 g06135459 Illustration 16 g06135455 16. Use Tooling (F) and a suitable press to install bearing (51) onto shaft assembly (49). Install retaining ring (50) onto shaft assembly (49). Illustration 17 g06136089 17. Use a suitable press to install shaft assembly (49) into rear mounting flange assembly (27). Use Tooling (E) to install retaining ring (47). Install plate (46) and O-ring seal (48) into rear mounting flange assembly (27). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERED ... 8/18 Illustration 18 g06134580 18. Install plate (45) and the O-ring seal. 19. Position rear mounting flange (43) onto rear mounting flange (27). Install bolts (44). Illustration 19 g06134480 20. Install bearing liners (42). Illustration 20 g06134276 21. Install swashplate assembly (40). Use Tooling (H) to hold slide (41) in the upright position. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERED ... 9/18 Illustration 21 g06134268 Illustration 22 g06134265 Improper assembly of parts that are spring loaded can cause bodily injury. To prevent possible injury, follow the established assembly procedure and wear protective equipment. 22. Install spring (39) and washers (38) into barrel assembly (33). 23. Use Tooling (D) and a suitable press to compress spring (39). Install retaining ring (37). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERE... 10/18 Illustration 23 g06134262 24. Install spring assembly (36) and shim (35) into barrel assembly (33). Illustration 24 g06134258 25. Install ball joint (34) onto barrel assembly (33). Illustration 25 g06134254 26. Install retainer plate (32) and piston assemblies (31) onto barrel assembly (33). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

D6K2 LGP, XL TRACK-TYPE TRACTOR EL700001-UP (MACHINE) POWERE... 11/18 Illustration 26 g06135808 27. Attach rear mounting flange (27) to Tooling (A). Use a nylon string to install rotating assembly (29). Install O-ring seal (30). Illustration 27 g06134236 28. Use Tooling (H) to hold port plate (28) in place. Install port plate (28) into pump housing (1). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/8/31

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com