Caterpillar Cat 993K Wheel Loader (Prefix Z4Z) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Service Repair Manual Models 993K WheelLoader

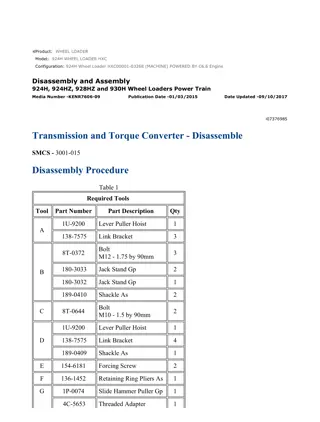

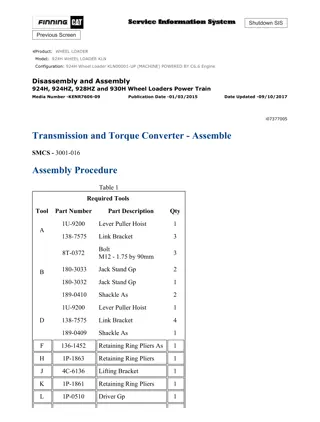

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 1/7 Shutdown SIS Previous Screen Product: WHEEL LOADER Model: 993K WHEEL LOADER Z4Z Configuration: 993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine Disassembly and Assembly 993K Wheel Loader Power Train Media Number -KENR5569-01 Publication Date -01/10/2012 Date Updated -05/07/2017 i02517748 Parking Brake - Disassemble SMCS - 4267-015 Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-0074 Slide Hammer Puller 1 B 8B-7557 Adapter 1 Start By: A. Remove the parking brake. Refer to Disassembly and Assembly, "Parking Brake - Remove". Illustration 1 g00350733 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 2/7 1. Remove bolts (1) that are used to disengage the parking brake. Illustration 2 g00351073 2. Install bolts (1) in the holes, as shown. Remove bolts (2) and the washers evenly. 3. Remove retaining plate (3) from brake housing (4) . Illustration 3 g00375378 4. Remove spacers (5) from the brake housing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 3/7 Illustration 4 g00375379 5. Use Tooling (A) and Tooling (B) in order to remove pistons (6) from the brake housing. Illustration 5 g00375380 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 6. Loosen bolts (7) evenly until the spring tension against brake housing (4) is released. Then remove bolts (7) and the washers. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 4/7 Illustration 6 g00375381 7. Use two persons to lift brake housing (4) off bearing cage assembly (8) . The weight of brake housing (4) is approximately 41 kg (90 lb). Illustration 7 g00375384 8. Remove lip seals (9) and O-ring seals (10) . Illustration 8 g00375385 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 5/7 9. Remove springs (11) from pressure plate (12) . Illustration 9 g00375387 10. Remove pressure plate (12) from bearing cage assembly (8) . Illustration 10 g00375388 11. Remove brake discs (13) and clutch plates (14) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 6/7 Illustration 11 g00375389 12. Remove bolt (15) and retainer (16) from the brake shaft. Illustration 12 g00375390 13. Remove seal (17) and hub (19) from brake shaft (18) . Illustration 13 g00375391 14. Use a rubber mallet to tap brake shaft (18) out of the bottom side of bearing cage assembly (8) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 7/7 Illustration 14 g00375412 15. Remove lip seal (20) , ring (21) and bearing (22) from bearing cage assembly (8) . 16. If necessary, remove dowels (23) . Copyright 1993 - 2020 Caterpillar Inc. Fri Mar 27 13:33:53 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 1/6 Shutdown SIS Previous Screen Product: WHEEL LOADER Model: 993K WHEEL LOADER Z4Z Configuration: 993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine Disassembly and Assembly 993K Wheel Loader Power Train Media Number -KENR5569-01 Publication Date -01/10/2012 Date Updated -05/07/2017 i07352468 Parking Brake - Assemble SMCS - 4267-016 Assembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-0074 Slide Hammer Puller Gp 1 B 8B-7557 Threaded Adapter 1 C 1P-0520 Driver Gp 1 Illustration 1 g00375412 1. Use Tooling (C) to install bearing (22), ring (21), and lip seal (20) in bearing cage assembly (8). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 2/6 2. If dowels (23) were removed, install the dowels. Illustration 2 g00379915 3. Turn bearing cage assembly (8) onto the opposite side. Use a rubber mallet to install brake shaft (18). Illustration 3 g00375390 4. Turn the bearing cage assembly onto the opposite side. Install hub (19) and seal (17) on brake shaft (18). Illustration 4 g00375389 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 3/6 5. Install retainer (16) and bolt (15) on the brake shaft. Tighten bolt (15) to a torque of 105 20 N m (78 15 lb ft). Illustration 5 g00375388 6. Install friction discs (13) and clutch plates (14) in alternating order. Start with a friction disc. Note: BXY00435-UP and ; BTW00177-UP have more clutch plates than friction discs. For these machines start with a clutch plate. Illustration 6 g00375387 7. Install pressure plate (12) on bearing cage assembly (8). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 4/6 Illustration 7 g00375385 8. Install springs (11) on pressure plate (12). Illustration 8 g00375384 9. Install O-ring seals (10) and lip seals (9) in the bores of the brake housing. Note: Lip seals (9) must contact the counterbore in the brake housing. Make sure that the sealing lips are facing outward. Lubricate the sealing lip with the lubricant that is being sealed. Illustration 9 g00375381 10. Use two persons to lift brake housing (4) onto bearing cage assembly (8). The weight of brake housing (4) is approximately 41 kg (90 lb). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 5/6 Illustration 10 g00375380 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 11. Install the washers and bolts (7) in brake housing (4). Tighten bolts (7) evenly to a torque of 270 40 N m (200 30 lb ft). Illustration 11 g00380075 12. Lubricate pistons (6) lightly with the lubricant that is being sealed. Use Tooling (A) and Tooling (B) to install pistons (6) in the brake housing. 13. Install spacers (5) in the brake housing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 6/6 Illustration 12 g00351073 14. Install retaining plate (3) on brake housing (4). 15. Install the washers and bolts (2) that secure retaining plate (3) to brake housing (4). Tighten the bolts (2) evenly to a torque of 105 20 N m (78 15 lb ft). 16. Remove bolts (1). Illustration 13 g00350733 17. Install bolts (1) into a different location. Bolts (1) are used to disengage the parking brake. End By: a. Install the parking brake. Refer to Disassembly and Assembly, "Parking Brake - Install". Copyright 1993 - 2020 Caterpillar Inc. Fri Mar 27 13:34:47 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 1/6 Shutdown SIS Previous Screen Product: WHEEL LOADER Model: 993K WHEEL LOADER Z4Z Configuration: 993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine Disassembly and Assembly 993K Wheel Loader Power Train Media Number -KENR5569-01 Publication Date -01/10/2012 Date Updated -05/07/2017 i02964861 Parking Brake - Install SMCS - 4267-012 Installation Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 138-7575 Link Bracket 3 B 1U-9200 Lever Puller Hoist 2 C 6V-6640 Sealant 1 1. Apply a thin bead of Tooling (C) to the mating surface of the parking brake assembly and the housing of the output transfer gear. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 2/6 Illustration 1 g01486835 Illustration 2 g01486836 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 3/6 Illustration 3 g01486840 2. Attach Tooling (A) and Tooling (B) to parking brake assembly (5). Tooling (A) should be installed onto parking brake assembly (5) only at bolt location (6). Bolts (6) and (9) are used to keep parking brake assembly (5) assembled. Bolts (6) and (9) are located next to notches (7) and (8). The weight of parking brake assembly (5) is approximately 158 kg (350 lb). Illustration 4 g01487154 3. Install parking brake assembly (5). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 4/6 Illustration 5 g01487153 4. Install bolts (10). Tighten bolts (10) to a torque of 270 40 N m (200 30 lb ft). Illustration 6 g01486838 5. Remove Tooling (A). Install the bolt and tighten the bolt that held Tooling (A) to a torque of 270 40 N m (200 30 lb ft). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 5/6 Illustration 7 g01486833 6. Connect hose assemblies (2), (3), and (4). Illustration 8 g01486815 Illustration 9 g01486813 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 6/6 7. Remove three bolts (1). Install bolts (1) into the storage location, as shown. Refer to Illustration 9. End By: a. Separate the steering frame lock. Refer to Disassembly and Assembly , "Steering Frame Lock - Separate and Connect". Copyright 1993 - 2020 Caterpillar Inc. Fri Mar 27 13:35:42 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 1/5 Shutdown SIS Previous Screen Product: WHEEL LOADER Model: 993K WHEEL LOADER Z4Z Configuration: 993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine Disassembly and Assembly 993K Wheel Loader Power Train Media Number -KENR5569-01 Publication Date -01/10/2012 Date Updated -05/07/2017 i04892747 Tire and Rim (Front) - Remove and Install SMCS - 4202-010-FR Removal Procedure Table 1 Required Tools Tool Part Number Part Description Qty 9U-7489 Lift Stand 2 A 277-7200 Hydraulic Pump 1 B 194-7586 Pneumatic Wrench Gp 1 C 155-3597 Wheel Chock 2 Start By: a. Connect the steering frame lock. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 2/5 Illustration 1 g03030981 1. Raise the lift arms. Place suitable cribbing under each of the lift arms, as shown. The measurements of the cribbing should be approximately 305 mm (12.0 inch) wide and 610 mm (24.0 inch) long. Lower the lift arms onto the suitable cribbing. Tilt the bucket forward so that the cutting edge of the bucket is resting on the ground. 2. Release the hydraulic system pressure. 3. Place Tooling (C) under the rear tires of the machine. Illustration 2 g03030987 4. Turn valve (1) to the Manual Lower position. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 3/5 Illustration 3 g03030992 5. Install Tooling (A) under the front frame of the machine, as shown. Use Tooling (A) to raise the front of the machine until the tires are off the ground. Illustration 4 g03031036 6. Disconnect harness assembly and clips (2). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 4/5 Illustration 5 g01522228 Illustration 6 g01522229 Illustration 7 g01522240 7. Attach a suitable lifting device to fender assembly (3). The weight of fender assembly (3) is approximately 158.7565 kg (350 lb). Remove bolts (4) and (5). 8. Remove fender assembly (3). Illustration 8 g01625570 Typical Example https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 5/5 9. Attach a suitable lifting device to tire and rim (6). The weight of tire and rim (6) is approximately 4082 kg (9000 lb). 10. Use Tooling (B) to remove nuts (7). Remove tire and rim (6). Installation Procedure Illustration 9 g03031063 1. Install tire and rim (6) in the reverse order of removal. a. Use Tooling (B) to tighten nuts (7) to a torque of 1800 200 N m (1328 147 lb ft). Copyright 1993 - 2020 Caterpillar Inc. Fri Mar 27 13:36:37 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 1/4 Shutdown SIS Previous Screen Product: WHEEL LOADER Model: 993K WHEEL LOADER Z4Z Configuration: 993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine Disassembly and Assembly 993K Wheel Loader Power Train Media Number -KENR5569-01 Publication Date -01/10/2012 Date Updated -05/07/2017 i03022384 Tire and Rim (Rear) - Remove and Install SMCS - 4202-010-RE Removal Procedure Table 1 Required Tools Tool Part Number Part Description Qty 9U-7489 Lift Stand 2 A 277-7200 Pump Group 1 B 194-7586 Pneumatic Wrench Gp 1 Note: Cleanliness is an important factor. Before the disassembly procedure, the exterior of the component should be thoroughly cleaned. This will help to prevent dirt from entering the internal mechanism. 1. Place chocks under the tires of the machine. Refer to Disassembly and Assembly, "Wheel Chock (Front, Rear)". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

993K Wheel Loader Z4Z00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 2/4 Illustration 1 g01435903 Note: Typical Example 2. Place a suitable block between the rear axle housing and the frame of the machine in order to prevent the rear axle from oscillating. Place the suitable block on both sides of the machine. Illustration 2 g01372667 3. Position Tooling (A) under the rear frame of the machine, as shown. Then, use Tooling (A) in order to raise the rear of the machine by approximately 305 mm (12 inch) until the rear tires are off of the ground. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/27

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com