Caterpillar Cat 993K Wheel Loader (Prefix Z4D) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Service Repair Manual Models 993K WheelLoader

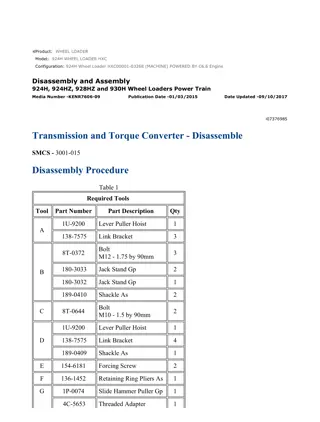

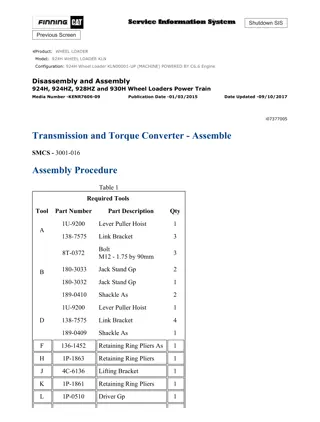

993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 1/3 Shutdown SIS Previous Screen Product: WHEEL LOADER Model: 993K WHEEL LOADER Z4D Configuration: 993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine Disassembly and Assembly 993K Wheel Loader Power Train Media Number -KENR5569-01 Publication Date -01/10/2012 Date Updated -05/07/2017 i05010234 Service Brake - Disassemble SMCS - 4251-015 Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty 138-7575 Link Bracket 2 A 6V-5684 Bolt 2 5P-8245 Hard Washer 2 Start By: a. Remove the service brake. Illustration 1 g03183017 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/28

993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 2/3 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 1. Remove bolts (1) and the washers. Use Tooling (A) and a suitable lifting device in order to remove reaction plate (2). The weight of reaction plate (2) is approximately 23 kg (50 lb). Illustration 2 g01495093 2. Remove thrust washer (4). Remove discs (3). Remove plates (6). Remove springs (5). Illustration 3 g01495273 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/28

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 3/3 Illustration 4 g01495113 3. Remove hub (7). Remove piston (8). Remove dowels (9). Apply shop air to Hole (Z). Illustration 5 g03183136 4. Remove thrust washer (10) and seals (11). Copyright 1993 - 2020 Caterpillar Inc. Sat Mar 28 07:36:10 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/28

993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 1/4 Shutdown SIS Previous Screen Product: WHEEL LOADER Model: 993K WHEEL LOADER Z4D Configuration: 993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine Disassembly and Assembly 993K Wheel Loader Power Train Media Number -KENR5569-01 Publication Date -01/10/2012 Date Updated -05/07/2017 i05009814 Service Brake - Assemble SMCS - 4251-016 Assembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty 138-7575 Link Bracket 2 A 6V-5684 Bolt 2 5P-8245 Hard Washer 2 B 369-9450 Grease 1 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/28

993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 2/4 Illustration 1 g03183136 1. Install thrust washer (10) and seals (11). Illustration 2 g01495273 2. Install dowels (9). Install piston (8). Install hub (7). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/28

993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 3/4 Illustration 3 g03183181 3. Install springs (5). Lubricate the discs before assembly. Install plates (6) and discs (3). Start with a plate (6) and end with a disc (3). Illustration 4 g03183197 4. Apply Tooling (B) to Surface (X). Install thrust washer (4) into reaction plate (1). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/28

993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 4/4 Illustration 5 g03183017 Improper assembly of parts that are spring loaded can cause bodily injury. To prevent possible injury, follow the established assembly procedure and wear protective equipment. 5. Use Tooling (A) and a suitable lifting device to install reaction plate (1). The weight of reaction plate (2) is approximately 23 kg (50 lb). Install bolts (2) and the washers. Tighten bolts (2) to a torque of 105 20 N m (77 15 lb ft). End By: a. Install the service brake. Copyright 1993 - 2020 Caterpillar Inc. Sat Mar 28 07:37:05 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/28

993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 1/3 Shutdown SIS Previous Screen Product: WHEEL LOADER Model: 993K WHEEL LOADER Z4D Configuration: 993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine Disassembly and Assembly 993K Wheel Loader Power Train Media Number -KENR5569-01 Publication Date -01/10/2012 Date Updated -05/07/2017 i03265175 Service Brake - Install SMCS - 4251-012 Installation Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 138-7575 Link Brackets 2 Note: Cleanliness is an important factor. Before assembly, all parts should be thoroughly cleaned in cleaning fluid. Allow the parts to air dry. Wiping cloths or rags should not be used to dry parts. Lint may be deposited on the parts which may cause later trouble. Inspect all parts. If any parts are worn or damaged, use new parts for replacement. Illustration 1 g01502074 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/28

993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 2/3 1. Install plug (5). Tighten plug (5) to a torque of 100 10 N m (74 7 lb ft). Install O-ring seal (4) . Illustration 2 g01502073 2. Install O-ring seals (3) . Illustration 3 g01502072 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/28

993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 3/3 Illustration 4 g01502071 3. Install Tooling (A) into service brake (2). The weight of service brake (2) is approximately 204 kg (450 lb). Install service brake (2). Install bolts (1). Tighten bolts (1) to a torque of 530 70 N m (390 51 lb ft). End By: Install the final drive and wheel. Refer to Disassembly and Assembly, "Final Drive, Brake and Wheel - Remove and Install". Copyright 1993 - 2020 Caterpillar Inc. Sat Mar 28 07:38:00 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/28

993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 1/9 Shutdown SIS Previous Screen Product: WHEEL LOADER Model: 993K WHEEL LOADER Z4D Configuration: 993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine Disassembly and Assembly 993K Wheel Loader Power Train Media Number -KENR5569-01 Publication Date -01/10/2012 Date Updated -05/07/2017 i05799974 Final Drive and Wheel - Disassemble SMCS - 4051-015 Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 439-3939 Link Brackets 2 B 2D-1201 Eyebolt 1 C 439-3941 Link Brackets 2 D 5P-5197 Retaining Ring Pliers As 1 Start By: A. Remove the final drive and wheel. Refer to Disassembly and Assembly , "Final Drive and Wheel - Remove". Note: Cleanliness is an important factor. Before the disassembly procedure, thoroughly clean the exterior of the component to prevent dirt from entering the internal mechanism. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/28

993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 2/9 Illustration 1 g01519848 Illustration 2 g01519849 1. Attach Tooling (A) and a suitable lifting device to planetary carrier (2) . The weight of planetary carrier (2) is approximately 544 kg (1200 lb). Remove bolts (1) . Remove planetary carrier (2) . Illustration 3 g01519850 2. Attach Tooling (B) and a suitable lifting device to pin (3) . Remove pin (3) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/28

993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 3/9 Illustration 4 g01519922 Illustration 5 g01519923 3. Remove thrust washer (4) . Place suitable cribbing next to lower thrust washer (4) under gear (5) in order to remove gear (5) . Use a suitable lifting device in order to remove gear (5) . The weight of gear (5) is approximately 63 kg (140 lb). Remove bushing (6) . Illustration 6 g03674963 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/28

993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 4/9 4. Remove remaining thrust washer (4) . Illustration 7 g01519851 5. Remove O-ring seal (7) . Illustration 8 g01519852 6. Attach Tooling (A) and a suitable lifting device to planetary carrier (8) . The weight of planetary carrier (8) is approximately 186 kg (410 lb). Remove planetary carrier (8) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/28

993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 5/9 Illustration 9 g01520025 Illustration 10 g01520026 7. Position planetary carrier (8) , as shown. Remove bolts (9) and the retainer. Remove shaft (12) . Remove thrust washers (10) and gear (11) . Remove bushing (13) . Repeat for remaining gears (11) . Illustration 11 g01519858 8. Remove gear (14) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/28

993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 6/9 Illustration 12 g01519859 9. Remove bolts (15) . Remove spacer (16) . Illustration 13 g01519860 10. Attach Tooling (C) and a suitable lifting device to retainer (17) . The weight of retainer (17) is approximately 59 kg (130 lb). Remove retainer (17) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/28

993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 7/9 Illustration 14 g01519862 11. Remove shims (18) . Illustration 15 g01519863 12. Attach a suitable lifting device to the hub and ring gear (19) . The weight of hub and ring gear (19) is approximately 435 kg (960 lb). Remove the hub and ring gear (19) . Illustration 16 g01519864 13. Position the hub and ring gear (19) , as shown. 14. Attach a suitable lifting device to hub (21) , as shown. The weight of hub (21) is approximately 124 kg (275 lb). Remove bolts (22) . Use Tooling (D) in order to remove retaining ring (20) . Remove hub (21) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/28

993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 8/9 Illustration 17 g01520243 15. Attach Tooling (C) and a suitable lifting device to wheel (23) . The weight of wheel (23) is approximately 1542 kg (3400 lb). Remove wheel (23) . Illustration 18 g01520183 16. Remove bearing cups (25) . Remove Duo-cone seal gp (26) . Illustration 19 g01519867 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/28

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

993K Wheel Loader Z4D00001-UP (MACHINE) POWERED BY C32 Engine(SEBP5... 9/9 17. Remove bearing cone (24) . Illustration 20 g01520186 18. Remove bearing cone (27) . Remove Duo-cone seal gp (28) . Copyright 1993 - 2020 Caterpillar Inc. Sat Mar 28 07:38:54 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/28

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com