Caterpillar Cat 955K TRACK LOADER (Prefix 71J) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn// n

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Service Repair Manual Models 955K TRACK LOADER

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 1/3 Shutdown SIS Previous Screen Product: TRACK LOADER Model: 955K TRACK LOADER 71J Configuration: 955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 ENGINE Disassembly and Assembly 955K TRACK-TYPE LOADER POWER TRAIN Media Number -REG00861-00 Publication Date -01/11/1993 Date Updated -10/10/2001 Flexible Coupling Drive Removal And Installation 1-Bolts (sixteen). 2-Joints (four). 3-Bolt, washer assembly, washer (assemble with concave side against washer assembly). 4-Flywheel output flange. 5-Torque converter input flange. Checking Flexible Drive Coupling Alignment Position engine in mounting location within the main frame. Check for correct engine-to- transmission alignment as follows: 1. Remove the torque converter input flange. 2. Fasten a 7H1942 Indicator (with a 7H1940 Universal Attachment) to the torque converter input shaft using a 7H1948 Snug, 7H1945 Holding Rod, 3/8 in. (9,5 mm) diameter rod 3 in. (76,2 mm) long and a 1J9778 Hose Clamp. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 2/3 CHECKING VERTICAL AND HORIZONTAL ALIGNMENT (Viewed from left side of machine.) Total indicator reading must not exceed .080 in. (2,03 mm). Correct any misalignment by adding or removing shims under engine rear supports. 3. Zero the indicator on the outside diameter of engine output flange as illustrated. Take an indicator reading every 90 while rotating the torque converter input shaft one complete turn. 4. Remove the 7H1940 Universal Attachment. Position the anvil of the dial indicator between the bolt holes and the ouside diameter of engine output flange as illustrated. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 3/3 CHECKING FACE ALIGNMENT (Viewed from left side of machine.) Total indicator reading must not exceed .026 in. (0,66 mm). Move front of engine as necessary to obtain correct dimension. 5. Zero the dial indicator. Take an indicator reading every 90 while rotating the torque converter input shaft one complete turn. 6. Recheck both settings and adjust if necessary. When alignment is correct, tighten engine mounting bolts as follows: a. Front mounting bolts - 460 50 lb. ft. (63,6 6,9 mkg). b. Rear mounting bolts - 225 30 lb. ft. (31,1 4,1 mkg). Misalignment If it is necessary to shift the engine from one side to the other in the frame, loosen the hold-down bolts and shift the engine accordingly. If the holes for the hold-down bolts are enlarged, dowels should be installed to hold the engine in the proper location after it is bolted down. Extreme misalignment is probably the result of bent main frame channels. They should be straightened. Extreme wear in the engine front support will also cause misalignment. Copyright 1993 - 2019 Caterpillar Inc. Sat Aug 31 14:24:40 UTC+0800 2019 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

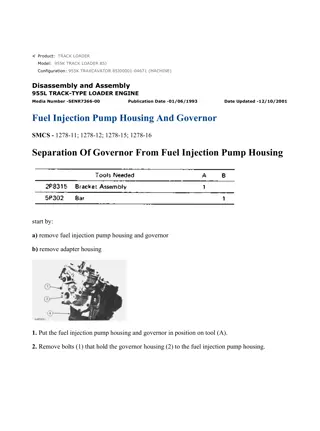

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 1/10 Shutdown SIS Previous Screen Product: TRACK LOADER Model: 955K TRACK LOADER 71J Configuration: 955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 ENGINE Disassembly and Assembly 955K TRACK-TYPE LOADER POWER TRAIN Media Number -REG00861-00 Publication Date -01/11/1993 Date Updated -10/10/2001 Transmission And Torque Converter Transmission Removal And Installation 1-Forged eyebolts (two 5/8" - 11 NC) (one 1/2" - 13 NC). Install and attach a hoist. 2-Transmission case-to-adapter bolts (ten). 3-Support bracket-to-frame bolts (two-not shown). 4-Transmission output shaft. Move transmission forward to clear output shaft before raising. Raise transmission about 3 in. (76,2 mm). 5-Support bracket. 6-Eyebolt and chain. 7-Transmission. Remove by tipping as shown. 6. Move the forward chain and eyebolt from the top of the torque converter housing to the top of the transmission mounting flange as shown. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 2/10 Removing Transmission From Case 1. Position the transmission vertically on a suitable stand or blocks. 2, 3, 4, 5-Bolts. Do not remove. 6-Bolts (two). Replace with 5/8" - 11 NC forged eyebolts. 7-Bolts (six). 8-Planetary transmission. Remove from transmission case and position vertically on blocks. Transmission Disassembly https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 3/10 This is a cross section of the planetary transmission. The shaded areas, in order of removal, are: A-No. 1 clutch, clutch housing and planet carrier. B-No. 2 clutch, clutch housing, ring gear and No. 1 ring gear. C-No. 3 clutch, clutch housing and ring gear, No. 1 and No. 2 sun gear, No. 2, No. 3 and No. 4 planet carrier. D-No. 4 clutch, clutch housing and ring gear. E-No. 5 clutch and ring gear. F-No. 5 clutch housing, No. 3, No. 4 and No. 5 sun gears, output shaft. A - No. 1 Clutch, Clutch Housing and Planet Carrier 1. Remove only the three bolts located by the "S" mark. When installing tighten to a torque of 85 5 lb. ft. (11,8 0,7 mkg). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 4/10 2-No. 1 clutch housing. Invert, remove the two 3/8" bolts and disassemble as shown. The exploded view is shown inverted. B - No. 2 Clutch, Clutch Housing, Ring Gear and No. 1 Ring Gear https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 5/10 1-Pins (two). Drive flush with face of carrier to allow retaining ring removal. C-No. 3 Clutch, Clutch Housing and Ring Gear, No. 1 and No. 2 Sun Gear, No. 2, No. 3 and No. 4 Planet Carrier 1-Remove bolt and retainer from inside of sun gear. Then remove sun gear and install 3/8" - 16 NC forged eyebolt as shown. 2-Clutch release springs (ten). 3-Clutch reaction pins (five). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 6/10 D-No. 4 Clutch, Clutch Housing and Ring Gear 1-Pins (two). Drive flush with face of carrier to allow retaining ring removal. E-No. 5 Clutch and Ring Gear https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 7/10 F-No. 5 Clutch Housing, No. 3, No. 4 and No. 5 Sun Gears and Output Shaft 1-Retaining ring. Must be removed first to allow output shaft to be lowered for removal of retaining ring at other end of shaft. Torque Converter Removal And Installation 1. Place transmission and torque converter unit on a suitable stand as shown. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 8/10 2-Bolts (two). Replace two diametrically opposite bolts with 3/8" - 16 NC forged eyebolts. 3-Bolts (fourteen). 4-Torque converter oil supply tube. 5-Guide pins (two). With torque converter in position shown, remove two retaining bolts and replace with 1/2" - 13 NC guide pins. 6-Bolts (five). 7-Retainer. 8-Output shaft. 9-Cover. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 9/10 5-Guide pins (two). 10-Forged eyebolt. Install 1/4" - 20 NC forged eyebolt and attach a hoist. Torque Converter Disassembly https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 ... 10/10 7, 26 Use an 8B7548 Push Puller, 8H663 Bearing Pulling Attachment and a S2398 Spacer to remove bearings. Copyright 1993 - 2019 Caterpillar Inc. Sat Aug 31 14:25:32 UTC+0800 2019 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 1/3 Shutdown SIS Previous Screen Product: TRACK LOADER Model: 955K TRACK LOADER 71J Configuration: 955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 ENGINE Disassembly and Assembly 955K TRACK-TYPE LOADER POWER TRAIN Media Number -REG00861-00 Publication Date -01/11/1993 Date Updated -10/10/2001 Transmission Hydraulic Controls Transmission Hydraulic Control Removal And Installation 1-Lever. 2-Lever. 3-Cover. 4-Clip. 5-Tube. Push into housing until clear of valve body. 6-Twelve-point head bolts (sixteen). 7-Six-point head bolts (five). Transmission Hydraulic Control Disassembly https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 2/3 Transmission Mechanical Control Linkage And Column 1-Grab iron assembly. 2-Knob. 3-Governor control linkage. 4-Bolts (six). 5-Column assembly. 6-Speed selector control rod. 7-Directional control rod. 8-Bracket. 9-Bolts (four). 10-Transmission control linkage. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 3/3 Copyright 1993 - 2019 Caterpillar Inc. Sat Aug 31 14:26:22 UTC+0800 2019 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

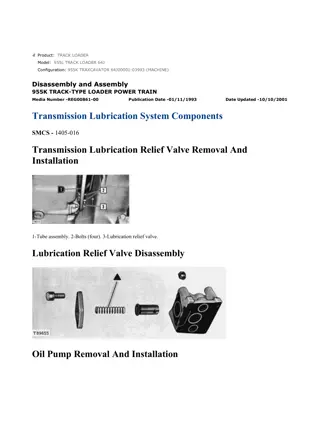

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 1/3 Shutdown SIS Previous Screen Product: TRACK LOADER Model: 955K TRACK LOADER 71J Configuration: 955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 ENGINE Disassembly and Assembly 955K TRACK-TYPE LOADER POWER TRAIN Media Number -REG00861-00 Publication Date -01/11/1993 Date Updated -10/10/2001 Transmission Lubrication System Components Transmission Lubrication Relief Valve Removal And Installation 1-Tube assembly. 2-Bolts (four). 3-Lubrication relief valve. Lubrication Relief Valve Disassembly Oil Pump Removal And Installation https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 2/3 1-Bolts (two). 2-Transmission oil pump. Oil Pump Disassembly 3, 6 Install bearings with joints at (A and B) as shown. Install bearings .062 in. (1,575 mm) below the inner surfaces of the cover and base. 4 Pump drive gear must rotate freely by hand. Transmission Oil Filter And Screen Removal And Installation 1-Bolts (two). 2-Oil pump supply tube and O-ring seal. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 3/3 3-Nuts (five). 4-Filter and screen group with O-ring seals. Transmission Oil Filter And Screen Disassembly Copyright 1993 - 2019 Caterpillar Inc. Sat Aug 31 14:27:14 UTC+0800 2019 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 1/2 Shutdown SIS Previous Screen Product: TRACK LOADER Model: 955K TRACK LOADER 71J Configuration: 955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 ENGINE Disassembly and Assembly 955K TRACK-TYPE LOADER POWER TRAIN Media Number -REG00861-00 Publication Date -01/11/1993 Date Updated -10/10/2001 Bevel Pinion Transmission Mounting Adapter Removal And Installation 1-Forged eyebolt (1/2"-13 NC) and nut. Install eyebolt and nut and attach a hoist. 2-Bolts (eleven). 3-Seal. Transmission Mounting Adapter Disassembly https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 2/2 Bevel Pinion, Bearing Cage And Pinion Locating Shims Removal And Installation 1-Bolts (four). 2-Bevel pinion bearing cage and bevel pinion. 3-Bevel pinion locating shims. NOTE: If the bevel gear location is changed or if a new bearing cage or pinion is installed, the pinion location must be checked. See BEVEL GEAR AND PINION SETTING. Bevel Pinion And Bearing Disassembly 1 Press spacer onto bevel pinion shaft before installing shaft. 2 Use an arbor press to remove bearing cones. 3 For correct installation see the GENERAL INSTRUCTIONS under BEARINGS - DOUBLE ROW, TAPERED ROLLER. Copyright 1993 - 2019 Caterpillar Inc. Sat Aug 31 14:28:05 UTC+0800 2019 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 1/6 Shutdown SIS Previous Screen Product: TRACK LOADER Model: 955K TRACK LOADER 71J Configuration: 955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 ENGINE Disassembly and Assembly 955K TRACK-TYPE LOADER POWER TRAIN Media Number -REG00861-00 Publication Date -01/11/1993 Date Updated -10/10/2001 Steering Clutch And Brake Controls Control Pedals Removal 1-Brake lock linkage. 2-Bracket. Remove two bolts securing bracket to support. 3-Left steering clutch control linkage. 4-Right steering clutch control linkage. 5-Caps (six). 6-Right brake control linkage. 7-Left brake control linkage. 8-Control pedal assemblies. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 2/6 This shows the pedals removed from the machine. The parts pointed out are: 9-Shims. Use as necessary to provide clearance between levers and pedals. Control Pedals And Support Brace Unit Removal And Installation 1-Right brake control rod. 2-Left brake control rod. 3-Left brake pedal return spring. 4-Right brake pedal return spring. 5 -Steering clutch control rods. 6-Tilt cylinder lines. 7-Center brake pedal return spring. 8-Parking brake lock ratchet. 9-Control pedals and support brace unit. Steering Clutch Oil Filter Removal And Installation https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 3/6 1-Steering clutch oil filter. Steering Clutch Oil Filter Disassembly Steering Clutch Oil Screen Steering Clutch Hydraulic Booster Removal 1. Remove steering booster cover. 2-Steering clutch hydraulic booster. Steering Clutch Hydraulic Booster Disassembly https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 4/6 Oil Pump Removal And Installation Viewed from rear. 1-Left steering clutch control rod. 2-Bolts (four). 3-Left steering clutch brake control rod. 4-Left steering clutch pedal. 5-Pump outlet oil line. 6-Pump inlet oil line. 7-Bolts (two). 8-Steering clutch oil pump. Oil Pump Disassembly https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 5/6 3,7 Align bearing joints (at A and B) and install bearings .062 in. (1,57 mm) below the inner surfaces of the cover and base. 4 Pump drive gear must rotate freely by hand. Steering Clutch Mechanical Components 1-Lever. Loosen bolt and remove key holding lever to shaft. 2-Lever and shaft. 3-Race. At assembly press onto shaft so top of race is 2.78 in. (70,6 mm) from upper end of shaft. Steering Clutch Case Cover 1-Bearings. Not to project above bottom of counterbore. Brake Engaging Mechanism https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 6/6 1-Cover. 2-Lever. 3-Key. 4-Bolt. Loosen and slide shaft through lever far enough to allow key to be removed from shaft. 5-Shaft. 6-Shaft assemblies. 7-Stop shaft. 8-Stop shaft. If stop shafts are removed from steering clutch case cover, the setscrews which hold the shafts in position must be adjusted when installing the shafts. To do this, tighten the setscrews, then back off 11/2 turns and lock with lock wire. Copyright 1993 - 2019 Caterpillar Inc. Sat Aug 31 14:28:56 UTC+0800 2019 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 1/16 Shutdown SIS Previous Screen Product: TRACK LOADER Model: 955K TRACK LOADER 71J Configuration: 955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 ENGINE Disassembly and Assembly 955K TRACK-TYPE LOADER POWER TRAIN Media Number -REG00861-00 Publication Date -01/11/1993 Date Updated -10/10/2001 Steering Clutches, Bevel Gear And Final Drive Steering Clutch Case Cover Removal Viewed from front of machine 1-Right brake control rod. 2-Left brake control rod. 3-Right pedal return spring. 4-Left pedal return spring. 5-Right steering clutch control rod. 6-Left steering clutch control rod. 7-Steering clutch case oil supply line. 8-Tube. 9-Cover. 10-Oil filter. 11-Steering booster cover. 12. Remove steering booster. 13 Pins. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 2/16 14-Bolts (eighteen). 15-Forged eyebolts (three). Install 3/8"-16 NC forged eyebolts and attach a hoist. 16-Steering clutch case cover. Steering Clutch And Bevel Gear Shaft Removal 1-Rod ends. When installing rod end and adjusting nut, adjust dimension between center of hole in rod end and outer face of adjusting nut to dimension shown. Lock with lock nut. 2-Bolts (twenty). 3-Bearing caps. The caps are marked L and R and should be installed on the correct side of the machine. Steering Clutch Removal 1-Lock. 2-Nut. Loosen until there is .25 in. (6,4 mm) between nut and hub. 3-Steering clutch, bearing and yoke. Pull https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

955L TRACK TYPE LOADER 71J04558-UP (MACHINE) POWERED BY 3304 EN... 3/16 the steering clutch from the shaft by using a 7F9540 Hydraulic Puller, 6F25 or 3S6224 Pump Group, 8B7548 Push Puller, two 8B7556 Adapters and an 8B7561 Step Plate. Steering Clutch Installation Be certain the splines on the bevel gear shaft and in the steering clutch driving drum are clean, dry and free from burrs. 1. With the splines meshing, push the clutch onto the shaft as far as possible by hand. 2. Using a 7M7236 Adapter Group, 7F9540 Hydraulic Puller and 6F25 or 3S6224 Pump Group, press the steering clutch driving drum onto the bevel gear shaft with a pressure of 15-20 tons (13,6 -18,1 M. tons). The distance between the face of the drum and the shoulder of the shaft must then be .12 .03 in. (3,0 0,8 mm). 3. Install the steering clutch retaining nut. Tighten to a torque of 250 50 lb. ft. (34,6 6,9 mkg). Install the lock. Steering Clutch Disassembly To remove or install locks (1) use a 7F9540 Hydraulic Puller, 6F25 or 3S6224 Pump Group, 8B7548 Push Puller, two 8B7556 Adapters, 8B7561 Step Plate and 7S8431 Spring Compressor Plate. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2019/8/31

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com