Caterpillar Cat 621E WHEEL SCRAPER (Prefix 6BB) Service Repair Manual Instant Download 3

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

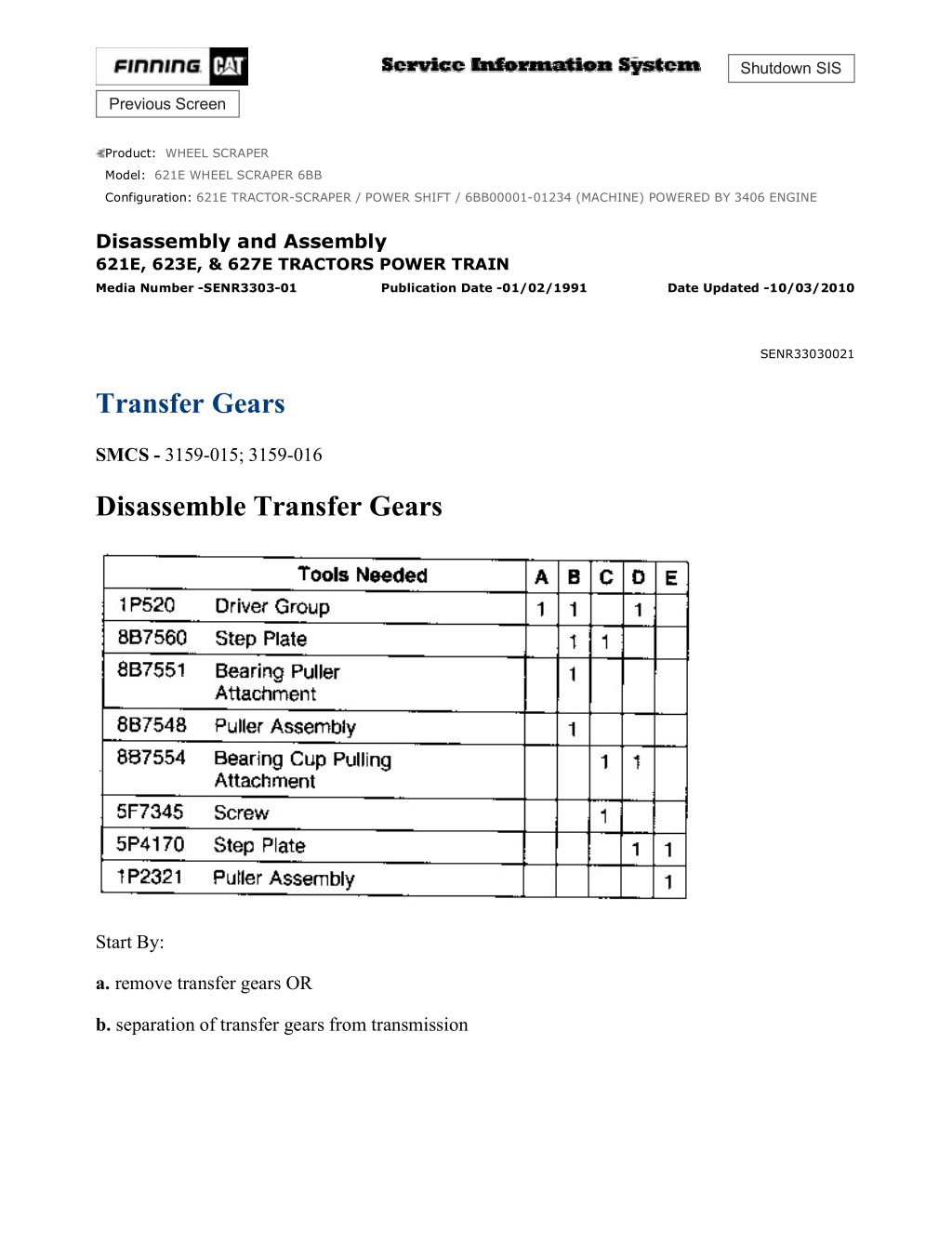

w 1/8(W) Shutdown SIS Previous Screen Product: WHEEL SCRAPER Model: 621E WHEEL SCRAPER 6BB Configuration: 621E TRACTOR-SCRAPER / POWER SHIFT / 6BB00001-01234 (MACHINE) POWERED BY 3406 ENGINE Disassembly and Assembly 621E, 623E, & 627E TRACTORS POWER TRAIN Media Number -SENR3303-01 Publication Date -01/02/1991 Date Updated -10/03/2010 SENR33030021 Transfer Gears SMCS - 3159-015; 3159-016 Disassemble Transfer Gears Start By: a. remove transfer gears OR b. separation of transfer gears from transmission https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 2/8(W) 1. Remove bolts (1), and remove filter housing (2). Remove the pumps (3). See the topic, Transmission Oil Pump. 2. Remove the bolts that hold cage (4). Install two 3/8" - 16 NC forcing screws (5), and remove the cage, shims (6), and gear (7). 3. Remove the bolts that hold cage (8). Install two 3/8" - 16 NC forcing screws (9), and remove the cage, shims (10), and gear (11). 4. Remove bearing cups (12) and (13) from the case assembly with a hammer and a punch. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 3/8(W) 5. Turn the transfer gear case over. Remove the bolts that hold cage (15). Install two 3/8" - 16 NC forcing screws (14), and remove cage (15), shims (16), and gear (17). 6. Remove bearing cup (18) from the case assembly with a hammer and a punch. 7. Turn the transfer gear case over. Remove three bolts (19). If required, install 3/8" - 16 NC forcing screws in holes 180 from the bolt holes, and remove gear (20). 8. Remove retaining ring (21). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

w 4/8(W) 9. Use a punch and a hammer to drive bearing (22) and carrier (23) from gear (20). 10. Remove bearing (22) from carrier (23). 11. Remove six bolts (24), and remove gear (25) from gear (17). Remove bearing cone (26) from gear (17) with tooling (B). 12. Remove bearing cone (27) from gear (11) and bearing cone (28) from gear (7) with tooling (E). 13. Remove bearing cup (29) from cage (8) with tooling (D). Remove O-ring seal (30) from the cage. 14. Remove bearing cup (31) from cage (15) with a hammer and punch. Remove bearing cone (32) from cage (4) with tooling (C). Remove O-ring seal (33) from cage (4). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 5/8(W) Assemble Transfer Gears 1. Install bearing (22) in carrier (23). 2. Install bearing (22) and carrier (23) on gear (20) with a hammer and a punch. Install retaining ring (21). 3. Install gear (20) in the transfer gear case, and install bolts (19). Tighten the bolts to a torque of 50 7 N m (37 5 lb ft). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 6/8(W) 4. Lower the temperature of bearing cups (29), (31), and (32). Install bearing cups (29), (31), and (32) with tooling (A). Make sure O-ring seals (30) and (33) are in position on the cages. 5. Heat bearing cone (26) to a maximum temperature of 149 C (300 F) and install it on gear (17). Install gear (25) on gear (17) and bolts (24) that hold it. Tighten the bolts to a torque of 50 7 N m (37 5 lb ft). 6. Heat bearing cone (27) to a maximum temperature of 149 C (300 F) and install it on gear (11). 7. Heat bearing cone (28) to a maximum temperature of 149 C (300 F) and install it on gear (7). 8. Turn the transfer gear case over. Lower the temperature of bearing cup (18), and install it with tooling (A). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 7/8(W) 9. Remove the forcing screws from the cage. Install gear (17), shims (16), cage (15) and the bolts that hold the cage. 10. Install tooling (F) and measure the end play in the gear with pry bar and blocks (34). Add or remove shims under the cage to get 0.15 0.05 mm (.006 .002 in.) end play in the gear. 11. Tighten the bolts that hold cage (15) to a torque of 50 7 N m (37 5 lb ft). 12. Turn the transfer gear case over. Lower the temperature of bearing cups (12) and (13), and install them with tooling (A). 13. Remove the forcing screws from the cage. Install gear (11), shims (10), cage (8) and the bolts that hold the cage. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 8/8(W) 14. Install tooling (F), and measure the end play in the gear. Add or remove shims under the cage to get 0.15 0.05 mm (.006 .002 in.)) end play in the gear. 15. Tighten the bolts that hold cage (8) to a torque of 50 7 N m (37 5 lb ft). 16. Remove the forcing screws from the cage. Install gear (7), shims (6), cage (4) and the bolts that hold the cage. Typical Example 17. Install tooling (F), and measure the end play in the gear. Add or remove shims under the cage to get 0.15 0.05 mm (.006 .002 in) end play in the gear. 18. Position filter housing (2) and install bolts (1) that hold it. Install pumps (3), see the topic, Transmission Oil Pump. Copyright 1993 - 2021 Caterpillar Inc. Sat Apr 3 08:35:47 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 1/2(W) Shutdown SIS Previous Screen Product: WHEEL SCRAPER Model: 621E WHEEL SCRAPER 6BB Configuration: 621E TRACTOR-SCRAPER / POWER SHIFT / 6BB00001-01234 (MACHINE) POWERED BY 3406 ENGINE Disassembly and Assembly 621E, 623E, & 627E TRACTORS POWER TRAIN Media Number -SENR3303-01 Publication Date -01/02/1991 Date Updated -10/03/2010 SENR33030022 Transmission Control Box SMCS - 3168-010 Remove And Install Transmission Control Box 1. Remove five bolts (1), and open door (2). 2. Disconnect wire harness (3) from the transmission control box. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 2/2(W) 3. Remove four bolts (4), and remove transmission control box (5). 4. To install the transmission control box, position it and install bolts (4) that hold it. 5. Connect wire harness (3). Close door (2), and install bolts (1) that hold it in place. Copyright 1993 - 2021 Caterpillar Inc. Sat Apr 3 08:36:43 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 1/2(W) Shutdown SIS Previous Screen Product: WHEEL SCRAPER Model: 621E WHEEL SCRAPER 6BB Configuration: 621E TRACTOR-SCRAPER / POWER SHIFT / 6BB00001-01234 (MACHINE) POWERED BY 3406 ENGINE Disassembly and Assembly 621E, 623E, & 627E TRACTORS POWER TRAIN Media Number -SENR3303-01 Publication Date -01/02/1991 Date Updated -10/03/2010 SENR33030023 Transmission Oil Filter SMCS - 3067-010 Remove And Install Transmission Oil Filter 1. Remove transmission oil filter (1) from transfer gear housing after four bolts (3) are removed. Remove bolts (2) from cover assembly. 2. Remove cover assembly (4) and filter element (5) from filter housing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 2/2(W) 3. Make a separation of the filter element (5) from cover assembly (4) after nut (7) is removed. Remove and inspect O-ring seal (6). Make a replacement if necessary. 4. Remove plug and seal (10) from filter housing, then remove spring (9) and spool (8). NOTE: The following steps are for the installation of the transmission oil filter. 5. Install spool (8), spring (9) and plug and seal (10) into transmission oil filter housing. Tighten plug to a torque of 47.5 6.8 N m (35 5 lb ft). 6. Install a new O-ring seal (6) on the filter cover. Install filter element (5) on cover with nut (7). Tighten the nut to a torque of 13.6 2.7 N m (120 24 lb.in.). Install filter element assembly in transmission oil filter housing. 7. Put transmission oil filter (1) on the transfer gear housing and install the four bolts (3) that hold it. Copyright 1993 - 2021 Caterpillar Inc. Sat Apr 3 08:37:38 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 1/17(W) Shutdown SIS Previous Screen Product: WHEEL SCRAPER Model: 621E WHEEL SCRAPER 6BB Configuration: 621E TRACTOR-SCRAPER / POWER SHIFT / 6BB00001-01234 (MACHINE) POWERED BY 3406 ENGINE Disassembly and Assembly 621E, 623E, & 627E TRACTORS POWER TRAIN Media Number -SENR3303-01 Publication Date -01/02/1991 Date Updated -10/03/2010 SENR33030024 Drive Shaft Group With Retarder SMCS - 3120-011; 3120-012; 3120-015; 3120-016; 3253 Remove Drive Shaft Group With Retarder 1. Remove the engine front hood and the engine rear hood. The weight of the hoods is approximately 33 kg (73 lb) and 28 kg (62 lb) respectively. 2. Remove the crankcase front guard and the crankcase rear guard. The weight of the guards is approximately 173 kg (381 lb) and 66 kg (146 lb) respectively. 3. Remove flywheel housing oil pump. 4. Remove the retarder valve on 627E Tractors. 5. Remove bolts (1). Remove cover (2) and the O-ring seal on the back side of the cover. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 2/17(W) 6. Remove spiral lockring (3). Install a 3/8" - 16 NC bolt in one of the tapped holes (4) in the end of the drive shaft. 7. Pull drive shaft (5) out approximately 610 mm (24.0 in) as shown. 8. Loosen clamps (6) and slide hose (7) onto tube assembly (8). Pry tube assembly (8) out of housing (10). Remove tube assembly (8) and hose (7). Remove the O-ring seal from tube assembly (8). If necessary, remove bolts (9) and housing (10) for easier removal of the tube assembly. 9. Disconnect hose (11) from the retarder housing. 10. Disconnect fitting (12). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 3/17(W) 11. Disconnect eighteen tube assemblies (13) from the bracket. 12. Remove bolts and clips (14). Remove two bolts (15), and move bracket (16) and tube assemblies (10) forward out of the way. 13. Disconnect and plug the ends of two hydraulic lines (17). Disconnect and plug the ends of two fuel lines (18). 14. Install a 1/2" - 13 NC forged eyebolt in boss (19) on top of the retarder housing and attach a hoist. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 4/17(W) NOTE: On tractors not equipped with the retarder, remove two of the bolts that hold the housing and replace them with two 7/16" - 14 x 2 1/4" bolts (19A). Remove the remaining bolts and nuts that hold the housing. Install three 7/16" - 14 NC forcing screws around the housing and force the housing out against the heads of bolts (19A). Fasten a 6V2156 Link Bracket (19B) and hoist to the top of the housing. Remove bolts (19A) and remove the drive shaft group. Lower the unit to the ground. The weight of the unit is approximately 36 kg (79 lb). NOTE: On tractors NOT equipped with the retarder, proceed to Install Drive Shaft Group With Retarder. 15. Remove ten bolts and two nuts that hold the retarder housing (21) to the flywheel housing. Install three 7/16" - 14 NC forcing screws (20), and remove retarder housing and drive shaft group. Lower the unit to the floor. The weight of the unit is 96 Kg (212 lb). Spring pressure is present behind plates. 16. Remove bolts (22) carefully and evenly to release the spring pressure. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 5/17(W) NOTE: When bolts are removed, the discs, plates, retainer and spring are free to fall. 17. Remove retainer (26), spring (25), plate (24), one disc assembly (27), plate (23) and other disc assembly (27) from the machine. The retainer, spring, plate and discs as a unit have a weight of 23 N m (50 lb.). Install Drive Shaft Group With Retarder NOTE: On tractors not equipped with the retarder, fasten a 6V2156 Link Bracket (19B) and hoist to the top of the drive shaft group housing. Position the housing and install 7/161/4 two " - 24 x 2 "bolts (19A). Remove the hoist and link bracket (19B). Install all but two bolts of the bolts and nuts that hold the housing. Remove the two bolts (19A), and install the last two bolts that hold the drive shaft group housing. Then, proceed to Step 15. NOTE: Friction discs (27) must be put in SAE 10W oil for a minimum of one hour before installation. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 6/17(W) 1. Put friction discs (27) and friction plate (23) in position in the flywheel housing. NOTE: The discs must be held in the flywheel housing while installation of the parts and tooling is made. NOTE: Gear (28) must be removed from the drive shaft and used to align the splines in the friction discs. 2. Put gear (28) in position in the flywheel. Make an alignment of the splines in the gear with the splines in friction discs (27). 3. Put plate (24), spring (25) and retainer (26) in place in the flywheel housing. Install three of the bolts (22) loosely to hold the assembly in position. 4. Put tooling (A) in position in gear (28) and the flywheel housing. Tooling (A) will put the discs and plate in a center position. 5. Install the bolts that hold the assembly in place. Tighten the bolts to a torque of 56 7 N m (42 5 lb ft). Remove the gear and tooling (A). 6. Install gear (28) on the shaft. Install the plate and the two bolts that hold the gear on the shaft. 7. Install a 1/2" - 13 NC forged eyebolt in the top of the retarder housing and attach a hoist. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 7/17(W) 8. Install two 7/16" - 14 guide bolts (29), 127 mm (5.0 in.) long as shown, and lift the housing into position and slide it on the guide bolts and onto the studs. 9. Lift the housing into position and slide it onto the studs. Slowly, turn the engine to make an alignment of gear (28) and the friction discs. Install the nuts and bolts that hold the housing in position. 10. Slide drive shaft (5) in and make an alignment of the external splines on the drive shaft with the internal splines of the shaft in the retarder housing. 11. Put tooling (B) in position in the bore of housing (10) to check alignment of the engine with the drive shaft. Make a rotation of tooling (B) in bore around the drive shaft until resistance is felt in both the clockwise and counterclockwise directions. 12. Find the center of free movement (travel) of tooling (B). This center is the direction the engine needs to be moved to make an alignment of the engine and drive shaft. 13. Inspect front and rear engine supports for damage. Make a replacement if necessary. Also, shims can be used to make an alignment of the engine and the drive shaft. 14. Pull the drive shaft at least two feet out the rear of the transmission. Remove tooling (B). 15. Remove the plugs from fuel lines (18) and connect them. Remove the plugs from hydraulic lines (17) and connect them. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 8/17(W) 16. Position bracket (16) and tube assemblies (10). Install bolts (15). Install bolts and clips (14). 17. Connect eighteen tube assemblies (13) to the bracket. 18. Connect fitting (12). 19. Connect hose (11) to the retarder housing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 9/17(W) 20. If housing (10) was removed, position it and install bolts (9) that hold it. 21. Make sure the O-ring seal is in position on the tube assembly. Put hose (7), clamps (6), and tube assembly (8) in position in the housing. Slide the hose in position and tighten clamps (6). 22. Install the drive shaft. See Step 10. Remove the bolt from the drive shaft. 23. Install spiral lockring (3). 24. Make sure the O-ring seal is in position on the back side of cover (2). Position the cover and install bolts (1) that hold it. 25. Install retarder valve. 26. Install flywheel housing oil pump. 27. Install the crankcase front and rear guards. 28. Install the engine front and rear holds. Disassemble Drive Shaft Group With Retarder Start By: a. remove drive shaft group with retarder https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 10/17(W) NOTE: Shaft (4) is free to fall when plate (2) is removed. 1. Remove two bolts (1), and remove plate (2). Use two pry bars and two wooden blocks to remove gear (3). 2. Remove shaft (4). Remove gear (5) from shaft (4). Remove race (6) if required. 3. Remove nine bolts (7). Use two 1/2" - 13 NC forcing screws and remove cover (8). 4. Remove nut and washer (9). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 11/17(W) 5. Remove gear (10) and shaft (11) as a unit from the cover. 6. Remove O-ring seal (12), washer (13), gear (10) and washer (14) from shaft (11). 7. Remove bearing (15) from gear (10). 8. Remove O-ring seal (16). Remove bearing (17) and remove lip type seal (18) from the cover. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 12/17(W) 9. Remove O-ring seal (19). 10. Remove twelve bolts (20), and remove stator (21). 11. Remove four bolts (22) from the opposite side. Remove retainer (23), deflector (24) and bearing (25). 12. Remove race (26) from the stator if necessary. 13. Remove rotor (27) from housing (28). 14. Remove three rings (29). The third ring is on the opposite side of the rotor. If necessary, remove retaining ring (30) and/or two carriers (31). The second carrier is on the opposite side of the rotor. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 13/17(W) 15. If necessary, remove race (32). Remove large O-ring seal (33). Assemble Drive Shaft Group With Retarder 1. Inspect all O-rings seals and lip type seals for wear or damage. 2. Make sure O-ring seal (33) is in position on the rotor. 3. If race (32) was removed, lower the temperature of a new replacement and install it. 4. If removed during disassembly, install retaining ring (3) and/or two carriers (31). The second carrier is on the opposite side of the rotor. 5. Install three rings (29). The third ring is on the opposite side of the rotor. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 14/17(W) 6. Position rotor (27) in housing (28). 7. If race (26) was removed from the stator during disassembly, lower the temperature of a new replacement and install it. 8. Position bearing (25), deflector (24), and retainer (23) in the stator. Put 9S3263 Thread Lock on bolts (22), and install them from the back side of the housing. Install twelve bolts (20). 9. Install O-ring seal (19). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 15/17(W) 10. Install bearing (17). Install lip type seal (18) in the cover with tool (A). Install the seal with the lip down into the cover, and install the seal even with the front of the counterbore. Install O-ring seal (16). 11. Install bearing (15) in gear (10) with tool (B). 12. Put washer (14), gear (10), washer (13) and O-ring seal (12) in position on shaft (11). Put a small amount of transmission oil on the O-ring seal. 13. Install gear (10) and shaft (11) as a unit on the cover. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 16/17(W) 14. Install nut and washer (9). Tighten the nut to a torque of 46 3 N m (34 2 lb ft). 15. Position cover (8), and install bolts (7). 16. If race (6) was removed during disassembly, heat a new replacement to 135 C (275 F) and install it until the race makes a seat with the shoulder of shaft (4). Install gear (5) on the shaft. 17. Gear (3) must remain off of shaft (4) until after the plate, discs, spring and retainer are installed on the flywheel. 18. See the topic, Install Drive Shaft Group With Retarder, for the remainder of the assembly of drive shaft group with retarder. End By: a. install drive shaft group with retarder https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

w 1/12(W) Shutdown SIS Previous Screen Product: WHEEL SCRAPER Model: 621E WHEEL SCRAPER 6BB Configuration: 621E TRACTOR-SCRAPER / POWER SHIFT / 6BB00001-01234 (MACHINE) POWERED BY 3406 ENGINE Disassembly and Assembly 621E, 623E, & 627E TRACTORS POWER TRAIN Media Number -SENR3303-01 Publication Date -01/02/1991 Date Updated -10/03/2010 SENR33030025 Transfer Gears, Torque Converter, Transmission And Differential SMCS - 3003; 3258-011; 3258-012 Remove Transfer Gears, Torque Converter, Transmission And Differential Start By: a. turn the tractor so it is at a right angle to the scraper b. remove the drive axles. (see topic, Drive Axles) c. remove the implement and elevator pumps * *This operation is located in the 623E Tractor Scraper, Vehicle Systems Disassembly And Assembly Module, Form No. SENR3318-01 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

w 2/12(W) 1. Remove two plugs (1) and drain the oil from the transmission. Remove plug (2) and drain the oil from the differential case. 2. Disconnect hose (3). Remove bolt and clip (4), and disconnect wire (5). Remove two bolts (6), and remove guard (7). 3. Remove bolt and clip (8). Disconnect wire (9). 4. Attach tooling (A) to transmission guard (10), remove bolts and remove guard. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/3

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com