Caterpillar Cat 621E WHEEL SCRAPER (Prefix 2TF) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

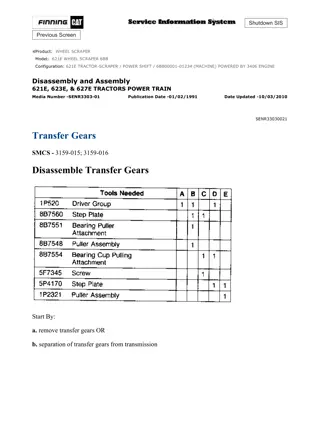

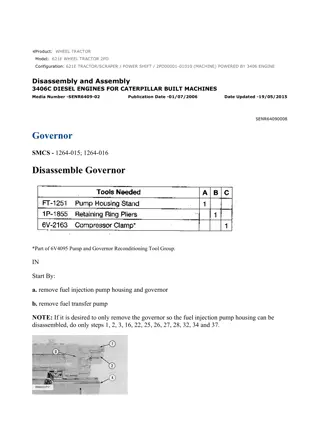

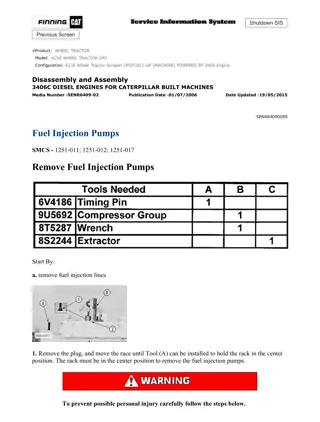

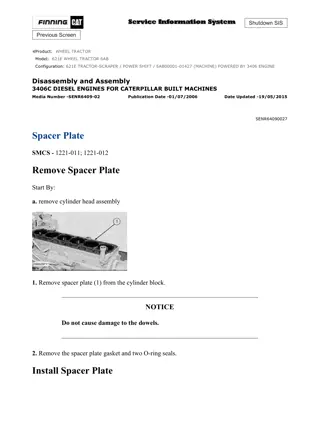

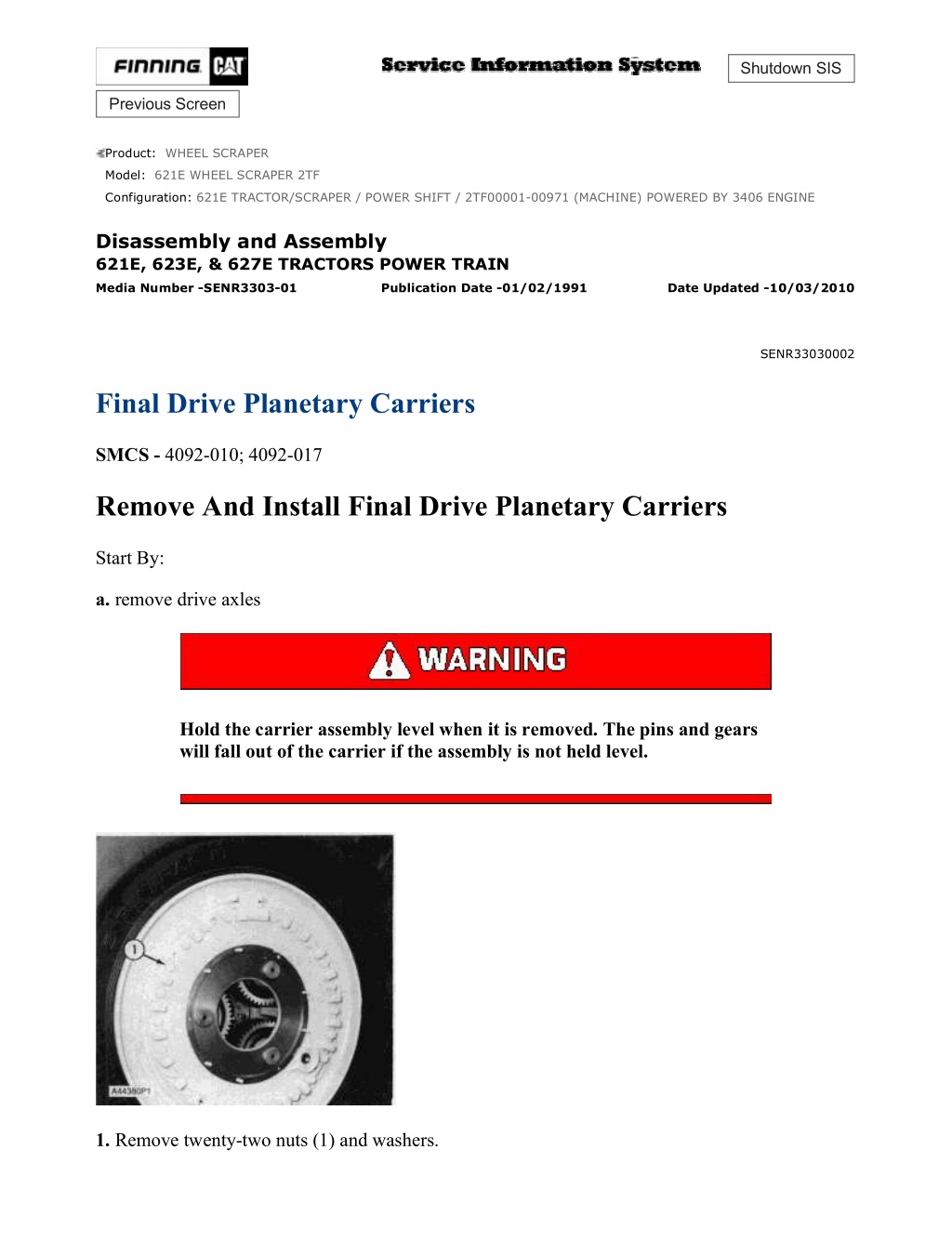

w 1/3(W) Shutdown SIS Previous Screen Product: WHEEL SCRAPER Model: 621E WHEEL SCRAPER 2TF Configuration: 621E TRACTOR/SCRAPER / POWER SHIFT / 2TF00001-00971 (MACHINE) POWERED BY 3406 ENGINE Disassembly and Assembly 621E, 623E, & 627E TRACTORS POWER TRAIN Media Number -SENR3303-01 Publication Date -01/02/1991 Date Updated -10/03/2010 SENR33030002 Final Drive Planetary Carriers SMCS - 4092-010; 4092-017 Remove And Install Final Drive Planetary Carriers Start By: a. remove drive axles Hold the carrier assembly level when it is removed. The pins and gears will fall out of the carrier if the assembly is not held level. 1. Remove twenty-two nuts (1) and washers. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 2/3(W) 2. Fasten a hoist to carrier assembly (2) and remove it from the hub assembly. Weight of the carrier assembly is approximately 150 kg (330 lb). 3. Check the condition of the O-ring seal on the carrier. If the seal has damage, use a new part for replacement. NOTE: The following steps are for the installation of the final drive planetary carriers. Hold the carrier assembly level when it is installed. The pins and gears will fall out of the carrier if the assembly is not held level. 4. Fasten a hoist to carrier assembly (2). Install the gear end of the drive axle in the carrier assembly as shown. The axle is used to hold the carrier assembly level and to help put the gears in the carrier assembly in alignment with the hub assembly. 5. Put the carrier assembly in position in the hub assembly. Remove the hoist and drive axle. 6. Install the twenty-two nuts that hold the carrier assembly in position. 7. Tighten the nuts to a torque of 370 50 N m (273 37 lb ft). End By: a. install drive axles Disassemble And Assemble Final Drive Planetary Carriers Start By: a. remove final drive planetary carriers https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

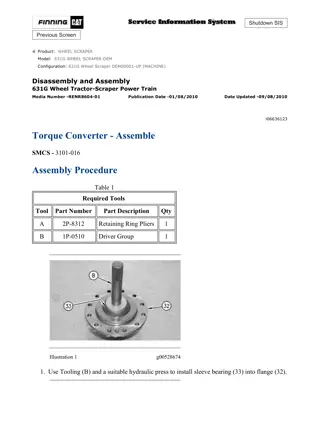

w 3/3(W) 1. Put the final drive planetary carrier on wood blocks as shown. 2. Remove pin (1) and the ring as a unit that holds gear (3) and two spacers (2) in position in the carrier assembly. 3. Remove the gear and two spacers from the carrier assembly. 4. Remove the other two gears from the carrier assembly as in Steps 1 through 3. 5. Remove two bearings (4) and spacer (5) from each gear. NOTE: The following steps are for the assembly of the final drive planetary carriers. 6. Install two bearings (4) and spacer (5) in each gear (3). 7. Put a spacer (2) on each side of the gear. Put the gear in position in the carrier assembly. 8. Install the ring and pin (1) that holds the gear in position. Turn pins (1) in the carrier until the flat side of the pins are toward the outside of the carrier as shown. 9. Install the other two gears in the carrier assembly as in Steps 7 and 8. End By: a. install final drive planetary carriers Copyright 1993 - 2021 Caterpillar Inc. Mon Apr 5 18:15:21 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

w 1/3(W) Shutdown SIS Previous Screen Product: WHEEL SCRAPER Model: 621E WHEEL SCRAPER 2TF Configuration: 621E TRACTOR/SCRAPER / POWER SHIFT / 2TF00001-00971 (MACHINE) POWERED BY 3406 ENGINE Disassembly and Assembly 621E, 623E, & 627E TRACTORS POWER TRAIN Media Number -SENR3303-01 Publication Date -01/02/1991 Date Updated -10/03/2010 SENR33030003 Final Drive Gears And Hubs SMCS - 4054-010; 4055 Remove And Install Final Drive Gears And Hubs Start By: a. remove final drive planetary carriers Put wood blocks under the outside edge of tire as supports to hold it in correct position before the hub and gear are removed. If supports are not used, the tire will fall and personal injury can be the result. 1. Remove bolts (2), ring (3) and the shims from the end of the axle housing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 2/3(W) 2. If retainer (1) is in the position shown, it must be removed to permit the installation of tool (A) in the groove of the gear. 3. Fasten tool (A) to a hoist. Put tool (A) in the groove of gear (4). Remove the gear and hub as a unit from the end of the axle housing. Weight of the unit is approximately 88.5 kg (195 lb). 4. Remove the retainers (1) that hold the gear and hub together. Remove the gear from the hub. Weight of the gear is 43 kg (95 lb). Weight of the hub is 45 kg (100 lb). NOTE: The following steps are for the installation of the final drive gears and hubs. NOTE: Before adjustment of the wheel bearings is started, check to be sure the bearing cups have a tight seat against the bottom of the bore in the wheel. Use a 0.03 mm (.001 in) or 0.05 mm (.002 in) feeler gauge to check for any clearance behind the bearing cup. If any clearance is found, use a bearing driver or press to move the bearing cup until it has a tight seat with no clearance. 5. Put gear (4) in position over the hub. Install the bolts, lock and retainers (1) that hold the unit together. 6. Fasten a hoist and tool (A) to the gear and hub. Put the unit in position on the end of the axle housing. 7. Make an adjustment to the wheel bearings as follows: a. Install ring (3) without shims. Install three bolts (2) the same distance apart to hold the ring. b. Tighten the bolts evenly to a torque of 35 N m (25 lb ft). c. Turn the wheel and tighten the three bolts again to a torque of 70 7 N m (50 5 lb ft) as the wheel is turned. Tighten each bolt only once. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 3/3(W) d. Use a depth micrometer and measure through the threaded holes in ring to find the average depth. Make a record of the average depth. e. Remove ring (3) and measure the thickness of the ring at the holes with the threads to find an average thickness. Make a record of the average thickness. f. Find the average difference between the two average measurements. This difference is the distance between the end of the axle housing and ring. Make a record of this distance. g. The average difference in Step 7f plug 0.30 mm (.012 in) is the amount of shims to install between the end of the axle housing and ring. h. Install the correct amount of shims, ring (3) and the bolts that hold the ring. Turn the wheel and tighten the bolts to a torque of 275 27 N m (200 20 lb ft) as the wheel is turned. Tighten each bolt only once. 8. To make an adjustment to the wheel bearings off the machine, see Adjustment Of Wheel Bearings "OFF" Machine in Specification, Form No. REG01621. End By: a. install final drive planetary carriers Copyright 1993 - 2021 Caterpillar Inc. Mon Apr 5 18:16:17 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 1/5(W) Shutdown SIS Previous Screen Product: WHEEL SCRAPER Model: 621E WHEEL SCRAPER 2TF Configuration: 621E TRACTOR/SCRAPER / POWER SHIFT / 2TF00001-00971 (MACHINE) POWERED BY 3406 ENGINE Disassembly and Assembly 621E, 623E, & 627E TRACTORS POWER TRAIN Media Number -SENR3303-01 Publication Date -01/02/1991 Date Updated -10/03/2010 SENR33030004 Tires And Wheels, Wheel Bearings And Duo-Cone Seals SMCS - 4200; 4208-011; 4208-012 Remove Tires And Wheels, Wheel Bearings And Duo-Cone Seals Start By: a. remove final drive gears and hubs Put wood blocks under the outside edge of the tire as supports to hold it in the correct position before the outer bearing cone is removed. If supports are not used, the tire will fall and personal injury can be the result. 1. Remove bearing cone (1). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 2/5(W) 2. Put the forks of a lift truck under the tire as shown. Fasten the tire and wheel to the lift truck so it does not fall when it is removed. 3. Remove the wood block supports from under the tire. Remove tire and wheel (2). Weight of the tire and wheel is approximately 900 kg (2000 lb). 4. Remove Duo-Cone seal (3) from the wheel. 5. Remove the two bearing cups from the wheel. 6. Remove Duo-Cone seal (6). 7. Remove bearing cone (5) and spacer (7). 8. Remove retainer assembly (4). 9. Remove the O-ring seal from the retainer assembly. Check the condition of the seal. If the seal has damage, use a new part for replacement. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 3/5(W) Install Tires And Wheels, Wheel Bearings And Duo-Cone Seals 1. Install a new O-ring seal in the retainer assembly. 2. Install retainer assembly (4) on the axle housing as shown. 3. Make sure the Duo-Cone seals are clean and dry. Make sure the metal surfaces that the seals make contact with are clean and dry. Put clean oil on the contact surfaces of the metal seals. 4. Install the Duo-Cone seal in the retainer assembly with tool (A). See the topic, Duo-Cone Floating Seals, Installation. 5. Install spacer (7) on the axle housing as shown. 6. Install bearing cone (5) on the axle housing as shown. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 4/5(W) 7. Lower the temperature of the two bearing cups and install them in the wheel. 8. Make sure the Duo-Cone seals are clean and dry. Make sure the metal surfaces that the seals make contact with are clean and dry. Put clean oil on the contact surfaces of the metal seals. 9. Install Duo-Cone seal in the wheel with tool (A). 10. Put the tire in position on the forks of a lift truck. Fasten the tire to the lift truck so it does not fall. 11. Put the tire in position on the axle housing. 12. Install the outer bearing cone (1). Put wood blocks under the outside edge of the tire as supports to hold the tire in the correct position before the lift truck is moved away. If supports are not used, the tire will fall and personal injury can be the result. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 5/5(W) End By: a. install final drive gears and hubs Copyright 1993 - 2021 Caterpillar Inc. Mon Apr 5 18:17:12 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 1/5(W) Shutdown SIS Previous Screen Product: WHEEL SCRAPER Model: 621E WHEEL SCRAPER 2TF Configuration: 621E TRACTOR/SCRAPER / POWER SHIFT / 2TF00001-00971 (MACHINE) POWERED BY 3406 ENGINE Disassembly and Assembly 621E, 623E, & 627E TRACTORS POWER TRAIN Media Number -SENR3303-01 Publication Date -01/02/1991 Date Updated -10/03/2010 SENR33030005 Brake Shoes And Brake Drums SMCS - 4252-012; 4252-011; 4253 Remove Brake Shoes And Brake Drums Start By: a. remove final drive gears and hubs 1. Remove the tire and wheel. See the topic, Remove Tire and Wheel, Wheel Bearings and Duo- Cone Seals. 2. Remove shield (1) and shield (3). Both brake springs are under tension. Wear safety glasses or goggles when removing these springs. Use only the correct tooling for this https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 2/5(W) procedure, do not substitute. Check tooling (A) for any wear or damage. Do not attempt to remove brake springs with damaged tooling. 3. Remove springs (2) with tool (A). 4. Remove lockwire (7) and two bolts (5). 5. Remove spring (4), retainer (6) and the felt washer from one side of each pin. 6. Remove two pins (8) and brake shoes (9). The weight of each brake shoe is 21 kg (46 lb.). NOTICE Remove the Duo-Cone seal from the wheel assembly before the brake drum is removed. The brake drum can cause damage to the Duo-Cone seal when it is removed. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 3/5(W) 7. Remove nuts (10) and lockwashers that hold the brake drum in position. 8. Fasten a hoist to brake drum (11) and remove it from the wheel assembly. Weight of the brake drum is 54.7 kg (120 lb). 9. Remove guard (12) from the wheel assembly. Install Brake Shoes And Brake Drums 1. Put guard (12) in position in the wheel assembly. 2. Fasten a hoist to brake drum (11) and put it in position in the wheel assembly. Install the washers and nuts that hold it. Tighten the nuts to a torque of 120 7 N m (90 5 lb ft). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 4/5(W) 3. Put upper brake shoe (9) in position on the axle housing. Install pin (8) that holds the brake shoe in position. 4. Install the felt washers, retainer (6) and spring (4). 5. Install the lower brake shoe as in Steps 3 and 4. 6. Install two bolts (5) and lockwire (7) that hold pins (8) in position. Both brake springs are under tension. Wear safety glasses or goggles when installing these springs. Use only the correct tooling for this procedure, do not substitute. Check tooling (A) for any wear or damage. Do not attempt to install brake springs with damaged tooling. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 5/5(W) 7. Install two springs (2) as shown with tool (A). 8. Install two shields (13). 9. Install the Duo-Cone seal in the wheel assembly. Install the tire and wheel. See the topic, Install Tire and Wheel, Wheel Bearings and Duo-Cone Seals. End By: a. install final drive gears and hubs Copyright 1993 - 2021 Caterpillar Inc. Mon Apr 5 18:18:08 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 1/3(W) Shutdown SIS Previous Screen Product: WHEEL SCRAPER Model: 621E WHEEL SCRAPER 2TF Configuration: 621E TRACTOR/SCRAPER / POWER SHIFT / 2TF00001-00971 (MACHINE) POWERED BY 3406 ENGINE Disassembly and Assembly 621E, 623E, & 627E TRACTORS POWER TRAIN Media Number -SENR3303-01 Publication Date -01/02/1991 Date Updated -10/03/2010 SENR33030006 Brake Camshafts And Slack Adjusters SMCS - 4261-012; 4261-011 Remove Brake Camshaft And Slack Adjuster 1. Remove the tire and wheel. See the topic, Remove Tires and Wheels, Wheel Bearings and Duo- Cone Seals. NOTE: The brake shoes are removed for better photo illustration of the brake camshaft and slack adjuster. 2. Put small wood blocks between the brake shoes and axle housing before the brake camshaft and slack adjuster is removed. The wood blocks will hold the brake shoes in position. 3. Remove pin (1) to disconnect the adjuster assembly from the brake rotochamber. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 2/3(W) 4. Remove ring (4) from the groove in the camshaft, and remove the washer. 5. Pull camshaft (6) out of the axle housing as shown. NOTE: Oil will drain out of location (2) when the camshaft is pulled out of the differential case and axle housing. 6. Remove the camshaft and slack adjuster (3). 7. Remove washer (5) from the camshaft. 8. Remove three seals (8) and two bearings (7) from the axle housing. Install Brake Camshaft And Slack Adjuster 1. Install bearing (9) in the axle housing with tool (A). 2. Install the lip type seal in the axle housing with tooling (A). Install the seal with the lip of the seal toward the differential case as shown. 3. Install bearing (10) in the axle housing with tooling (A). Install the bearing until it is 7.14 mm (.281 in.) below the outside surface of the axle housing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 3/3(W) 4. Install the two lip type seals on each side of bearing (10) with tooling (A). Install the seals even with the outside surface of the axle housing and with the lips of the seals toward the differential case as shown. 5. Install washer (5) on camshaft (6). Slide the camshaft through the axle housing and install the washer and ring (4) on the camshaft. 6. Put slack adjuster (3) in position on the camshaft and install the end of the camshaft in the axle housing. 7. Put ring (4) in the groove on the camshaft. 8. Put the slack adjuster in position in the rod of the brake rotochamber. Install pin (1) and the cotter pin. 9. Install the tires and wheels. See the topic, Install Tire and Wheels, Wheel Bearings and Duo- Cone Seals. Copyright 1993 - 2021 Caterpillar Inc. Mon Apr 5 18:19:04 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 1/1(W) Shutdown SIS Previous Screen Product: WHEEL SCRAPER Model: 621E WHEEL SCRAPER 2TF Configuration: 621E TRACTOR/SCRAPER / POWER SHIFT / 2TF00001-00971 (MACHINE) POWERED BY 3406 ENGINE Disassembly and Assembly 621E, 623E, & 627E TRACTORS POWER TRAIN Media Number -SENR3303-01 Publication Date -01/02/1991 Date Updated -10/03/2010 SENR33030007 Adjustment Of Brakes SMCS - 4253; 4261-025 Adjustment Of Brakes NOTE: The maximum amount of movement [distance (A)] of the rod before adjustment is needed is 76.2 mm (3.00 in). 1. Loosen screw (1). 2. Turn shaft (2) until the movement [distance (A)] of the rod is 41.1 mm (1.62 in.) (cold) when the brakes are engaged. 3. Tighten screw (1). Copyright 1993 - 2021 Caterpillar Inc. Mon Apr 5 18:19:59 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 1/2(W) Shutdown SIS Previous Screen Product: WHEEL SCRAPER Model: 621E WHEEL SCRAPER 2TF Configuration: 621E TRACTOR/SCRAPER / POWER SHIFT / 2TF00001-00971 (MACHINE) POWERED BY 3406 ENGINE Disassembly and Assembly 621E, 623E, & 627E TRACTORS POWER TRAIN Media Number -SENR3303-01 Publication Date -01/02/1991 Date Updated -10/03/2010 SENR33030008 Axle Housing SMCS - 3260-010 Remove And Install Axle Housings Start By: a. remove brake shoes and brake drums b. remove brake camshafts and slack adjusters 1. Drain the oil from the differential case. 2. Fasten axle housing (2) to the fork of a lift truck as shown. 3. Remove nuts (1) and washers that hold the housing in position. Remove the housing. The weight of the housing is approximately 190 kg (422 lb). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 2/2(W) 4. Check O-ring seal (3) for damage. If the seal has damage, use a new part for replacement. NOTE: The following steps are for the installation of the axle housings. 5. Install O-ring seal (3) on the axle housing. 6. Fasten axle housing (2) to the fork of a lift truck. Put the housing in position on the studs in the differential case. 7. Put 9M3710 Anti-Seize Compound on the threads of the studs. Install the nuts that hold the axle housing in position. Tighten the nuts to a torque of 295 14 N m (215 10 lb ft). 8. Fill the differential case with oil to the correct level. See the Operation and Maintenance Manual. End By: a. install brake camshafts and slack adjusters b. install brake shoes and brake drums Copyright 1993 - 2021 Caterpillar Inc. Mon Apr 5 18:20:55 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 1/5(W) Shutdown SIS Previous Screen Product: WHEEL SCRAPER Model: 621E WHEEL SCRAPER 2TF Configuration: 621E TRACTOR/SCRAPER / POWER SHIFT / 2TF00001-00971 (MACHINE) POWERED BY 3406 ENGINE Disassembly and Assembly 621E, 623E, & 627E TRACTORS POWER TRAIN Media Number -SENR3303-01 Publication Date -01/02/1991 Date Updated -10/03/2010 SENR33030009 Brake Actuator SMCS - 4262-017; 4262-010 Remove And Install Brake Actuator To prevent personal injury, do not disconnect any air lines until the air pressure is zero. 1. Drain the air from the air tanks. 2. Disconnect air hose assemblies (1) and (2) from the brake actuator. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 2/5(W) 3. Loosen Screw (3). Loosen shaft (4) until the pin that holds the rod in the actuator to the slack adjuster can be removed. 4. Remove the cotter pin and pin (5). 5. Remove nuts (7) that hold the brake actuator in position, and remove brake actuator (6). NOTE: The following steps are for the installation of the brake actuator. 6. Position brake actuator (6) on the bracket, and install the nuts that hold it. Tighten nuts (7) to a torque of 180 25 N m (135 18 lb ft). 7. Connect air hose assemblies (1) and (2) to the brake actuator. 8. Put the slack adjuster in position on the rod for the brake actuator, and install pin (5) and the cotter pin that holds it. 9. Make an adjustment to the brakes. See the topic, Adjustment Of Brakes. Disassemble And Assemble Brake Actuator Start By: a. remove brake actuator https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 3/5(W) 1. Remove yoke (1), locknut (19), boot (3), and retainer (4). Remove clamp (12), plate (11), and diaphragm (9). To prevent personal injury, remove nut (2) very slowly to be certain all the pressure on the service brake spring is released. 2. Remove the locknut for nut (2). Remove nut (2) slowly to release pressure on service brake spring (7). Remove rod (10), retainer (15), spring (7) and the guide. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 4/5(W) Be very careful when using tooling (A) to compress and release parking brake spring (6). Serious injury could result if care is not used during this process. 3. Install tooling (A) to compress parking brake spring (6) slightly. Remove eight bolts (13), (photo shows bolts removed). Remove nut (22) slowly to release pressure on spring (6). 4. Remove tooling (A). Remove spring (6). Remove seal and wiper (17) from piston (5). 5. Remove wiper (23) and seal (24) from the cylinder assembly (14). NOTE: The following steps are for the assembly of the brake actuator. 6. Clean and inspect all parts. Make a replacement of all parts that are worn or damaged. 7. Install seal (24) and wiper (23) in the cylinder assembly (14). Serious injury could result if tooling (A) is not used correctly and safely to compress parking brake spring (6). 8. Install seal and wiper (17) in piston (5). Install spring (6). Install tooling (A) to compress the parking brake spring. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 5/5(W) 9. Slowly, tighten nut (22) and compress parking brake spring (6). Install eight bolts (13), (photo shows bolts removed). 10. Install the guide, spring (7), retainer (15) and rod (10). 11. Install and tighten nut (2) to put pressure on the service brake spring (7). Tighten nut (2) until approximately 1/161/8 51.5 to 54.0 mm (2 to 2 in) of rod (10) is out of the nut. Install the locknut on the rod above nut (2). 12. Install diaphragm (9), plate (11), and clamp. Install retainer, boot (3), locknut (19), and yoke (1). End By: a. install brake actuator Copyright 1993 - 2021 Caterpillar Inc. Mon Apr 5 18:21:51 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 1/4(W) Shutdown SIS Previous Screen Product: WHEEL SCRAPER Model: 621E WHEEL SCRAPER 2TF Configuration: 621E TRACTOR/SCRAPER / POWER SHIFT / 2TF00001-00971 (MACHINE) POWERED BY 3406 ENGINE Disassembly and Assembly 621E, 623E, & 627E TRACTORS POWER TRAIN Media Number -SENR3303-01 Publication Date -01/02/1991 Date Updated -10/03/2010 SENR33030010 Brake Control Valve SMCS - 4265-017; 4265-010 Remove And Install Brake Control Valve 1. Let the air out of the reservoirs. 2. Remove five bolts (1), and open access door (2). 3. Remove line (3), and remove two lines (4). Disconnect linkage lever (5). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 2/4(W) NOTE: On 627E Tractors, disconnect two electrical wires (6) and remove switch (7). Remove line (8). 4. Remove bolts (9), and remove brake control valve (10). NOTE: The following steps are for the installation of the brake control valve. 5. Position the brake control valve, and install bolts (9). 6. Connect linkage lever (5). Install two lines (4), and install line (3). NOTE: On 627E Tractors, install line (8). Install switch (7), and connect two electrical wires (6). 7. Close access door (2), and install five bolts (1). Disassemble And Assemble Brake Control Valve Start By: a. remove brake control valve https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

w 3/4(W) 1. Remove bolt and washer (3), seat (4), retainer (5), rubber spring (2), piston assembly (18), and spring (6) from the body. 2. Remove seal (1) from piston assembly (18). 3. Remove ring (13), bolt (12), washer (11), diaphragm (10), and spring (7). Remove seat (8), O- ring seal (9), spring (15), retainer (16) and valve (17). 4. Remove seal (14) from valve (17). Check the condition of all the seals. If any are worn or damaged, make a replacement of the seal with a new part. NOTE: The following steps are for the assembly of the brake control valve. 5. Install seal (14) on valve (17). Install valve (17), retainer (16), spring (15), O-ring seal (9), and seat (8). 6. Install spring (7), diaphragm (10), washer (11), bolt (12), and ring (13). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

w 4/4(W) 7. Install seal (1) on piston assembly (18). Install spring (6), piston assembly (18), retainer (5), seat (4), and bolt and washer (3). End By: a. install brake control valve Copyright 1993 - 2021 Caterpillar Inc. Mon Apr 5 18:22:47 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/5

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com