Caterpillar Cat 3512C Locomotive Engine (Prefix RR6) Service Repair Manual Instant Download (RR600001 and up)

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

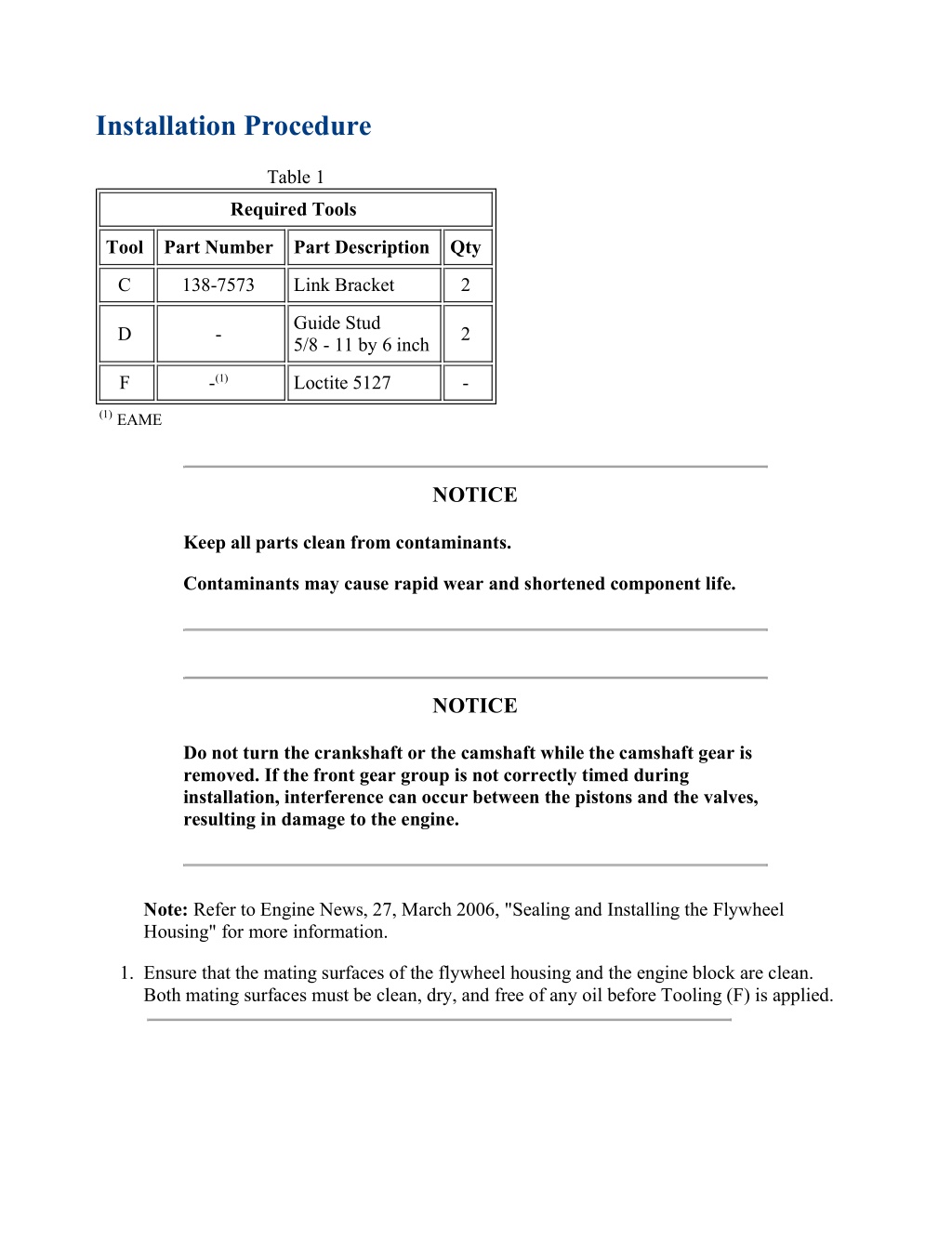

w 4/9(W) Installation Procedure Table 1 Required Tools Tool Part Number Part Description Qty C 138-7573 Link Bracket 2 Guide Stud 5/8 - 11 by 6 inch D - 2 -(1) F Loctite 5127 - (1)EAME NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. NOTICE Do not turn the crankshaft or the camshaft while the camshaft gear is removed. If the front gear group is not correctly timed during installation, interference can occur between the pistons and the valves, resulting in damage to the engine. Note: Refer to Engine News, 27, March 2006, "Sealing and Installing the Flywheel Housing" for more information. 1. Ensure that the mating surfaces of the flywheel housing and the engine block are clean. Both mating surfaces must be clean, dry, and free of any oil before Tooling (F) is applied. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/4/24

w 5/9(W) Illustration 1 g01317446 2. Apply a 6.0 mm (0.25 inch) bead of Tooling (F) to the mating surface of the flywheel housing. Refer to Illustration 1. Illustration 2 g01316311 3. Install Tooling (D) into the cylinder block. 4. Install Tooling (C) and a suitable lifting device on flywheel housing (16). The weight of flywheel housing (16) is approximately 235 kg (518 lb). 5. Lift the flywheel housing into position onto Tooling (D). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/4/24

w 6/9(W) 6. Install bolts (17) and the hard washers that secure the flywheel housing to the cylinder block. Remove Tooling (D) and install remaining bolts (17) and the hard washers. Note: Refer to Parts Manual for the correct positions for bolts that secure the flywheel housing to the cylinder block. 7. Tighten bolts (17) evenly. Tighten the 1/2 - NC bolts to a torque of 135 20 N m (100 15 lb ft). Tighten the 5/8 - NC bolts to a torque of 270 40 N m (200 30 lb ft). 8. Tighten plugs (15) to a torque of 70 15 N m (50 11 lb ft). 9. Install the crankshaft rear seal and the wear sleeve. Refer to Disassembly and Assembly, "Crankshaft Rear Seal and Wear Sleeve - Install". Illustration 3 g01140296 10. Install timing bolt (5) in the flywheel. Ensure that timing pin (2) is installed in each camshaft. Refer to Testing and Adjusting, "Camshaft Timing". Refer to Testing and Adjusting, "Finding the Top Center Position for the No. 1 Piston". Illustration 4 g01316352 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/4/24

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

w 7/9(W) Illustration 5 g01316354 11. Use the following procedure to install camshaft drive gear (11) and camshaft drive gear (14). a. Clean the taper of the camshaft and the tapered bore of the camshaft gear with a lint free cloth saturated with solvent to remove oil. Clean the parts again with a lint free alcohol wipe to remove any residue. The alcohol wipe will dirty after cleaning the parts. Clean the parts again with a lint free alcohol wipe until no residue is left on the alcohol wipe. Note: The taper of the camshaft and the tapered bore of the camshaft gear must be clean, dry, and free of residue before assembly. b. Ensure that the camshaft timing pins and the timing pin for the flywheel are installed. c. Place camshaft drive gear (11) and camshaft drive gear (14) in position. Remove the backlash by rotating the gears in the opposite direction of camshaft rotation. Note: For "Standard Rotation" engines, turn the camshaft drive gears COUNTERCLOCKWISE. For "Reverse Rotation" engines, turn the camshaft drive gears CLOCKWISE. d. Install bolt (9) and plate (10). e. Install bolt (12) and ring (13). Ensure that the hole in the ring is properly seated on the locating pin. f. Tighten the bolt to a torque of 360 N m (265 lb ft). g. Place a mark on the bolt. h. Place a driver against the retaining plate of the camshaft drive gear. Strike the driver with a hammer, three times, or four times. i. Tighten the bolt again to a torque of 360 N m (265 lb ft). j. Repeat Steps 11.h and 11.i until the mark has turned at least 90 degrees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/4/24

w 8/9(W) Illustration 6 g01126909 12. Remove the timing pin from the camshafts. Install timing pin (2) in the storage position. Install rear camshaft covers (1). 13. Remove the timing bolt from the flywheel. Install plug (4) in the timing hole. Install cover (3) and timing bolt (5) in the storage position on the flywheel housing. Illustration 7 g01126908 14. Install tube (6) if equipped. 15. Install the gaskets on the elbows. Install drain tubes (7) for the turbochargers. 16. Install the gasket and covers (8) on the flywheel housing. End By: https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/4/24

w 9/9(W) a. Install the engine speed/timing sensor. Refer to Disassembly and Assembly, "Engine Speed/Timing Sensor - Remove and Install". b. Install the engine speed sensor. Refer to Disassembly and Assembly, "Engine Speed Sensor - Remove and Install". c. Install the engine oil pan. Refer to Disassembly and Assembly, "Engine Oil Pan - Install". d. If the exhaust elbow was removed, install the exhaust elbow. Refer to Disassembly and Assembly, "Exhaust Elbow - Remove and Install". e. Install the starting motors. Refer to Disassembly and Assembly, "Air Starting Motor - Install". Refer to Disassembly and Assembly, "Electric Starting Motor - Remove and Install". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/4/24

w 4/10(W) Removal Procedure Start By: a. Remove the front housing. Refer to Disassembly and Assembly, "Housing (Front) - Remove". b. Remove the flywheel housing. Refer to Disassembly and Assembly, "Flywheel Housing - Remove". NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Illustration 1 g01135024 1. Remove bolts (1) and thrust plate (2). Remove balancer gear (3) from the balancer gear shaft. Note: The balancer gear is for the 3508C engine. The 3512C Engine, 3512E Engine, and the 3516C Engine do not have the balancer gear on the front of the engine. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/4/24

w 5/10(W) Illustration 2 g01135028 Personal injury can result from parts and/or covers under spring pressure. Spring force will be released when covers are removed. Be prepared to hold spring loaded covers as the bolts are loosened. 2. Remove bolts (4) and cover (5) from the front of the cylinder block. 3. Remove plunger assembly (6) and spring (7) from the cylinder block. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/4/24

w 6/10(W) Illustration 3 g01135030 4. Remove bolts (12) and thrust plate (13). Remove cluster idler gear (14) from the rear of the cylinder block. 5. Remove bolts (8), idler shaft (9), camshaft idler gear (10), and thrust washer (11). Illustration 4 g01135029 Personal injury can result from parts and/or covers under spring pressure. Spring force will be released when covers are removed. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/4/24

w 7/10(W) Be prepared to hold spring loaded covers as the bolts are loosened. 6. Remove bolts (15) and cover (16) from the rear of the cylinder block. 7. Remove plunger assembly (17) and spring (18) from the cylinder block. Installation Procedure NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Illustration 5 g01135029 Improper assembly of parts that are spring loaded can cause bodily injury. To prevent possible injury, follow the established assembly procedure and wear protective equipment. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/4/24

w 8/10(W) 1. Apply clean engine oil on spring (18) and plunger assembly (17). 2. Install spring (18) and plunger assembly (17) in the cylinder block. 3. Install cover (16) and bolts (15). Illustration 6 g01135030 4. Apply clean engine oil to the sleeve bearing in camshaft idler gear (10) and idler shaft (9). Install idler shaft (9) in camshaft idler gear (10). Position camshaft idler gear (10) and thrust washer (11) and install bolts (8). Tighten bolts (8) to a torque of 240 20 N m (177 15 lb ft). 5. Apply clean engine oil on the sleeve bearing in cluster idler gear (14) and the cluster gear shaft. Install cluster idler gear (14) on the cluster gear shaft. Make sure that the marks on cluster idler gear (14) and the crankshaft gear are in alignment with the rotation of the engine. Install thrust plate (13) and bolts (12). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/4/24

w 9/10(W) Illustration 7 g01135028 Improper assembly of parts that are spring loaded can cause bodily injury. To prevent possible injury, follow the established assembly procedure and wear protective equipment. 6. Apply clean engine oil on spring (7) and plunger assembly (6). 7. Install spring (7) and plunger assembly (6) in the cylinder block. 8. Install cover (5) and bolts (4). Illustration 8 g01135024 9. Apply clean engine oil on the sleeve bearing in balancer gear (3) and the balancer gear shaft. Install balancer gear (3) on the balancer gear shaft. Make sure that the marks on balancer gear (3) and the crankshaft gear are in alignment with the rotation of the engine. Install thrust plate (2) and bolts (1). Note: The balancer gear is for the 3508C engine. The 3512C engine, 3512E Engine, and the 3516C Engine do not have the balancer gear on the front of the engine. End By: a. Install the flywheel housing. Refer to Disassembly and Assembly, "Flywheel Housing - Install". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/4/24

w 10/10(W) b. Install the front housing. Refer to Disassembly and Assembly, "Housing (Front) - Install". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/4/24

w 4/7(W) Removal Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-0520 Driver Group 1 Start By: a. Remove the flywheel housing. b. Remove the crankshaft rear seal and wear sleeve. NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Illustration 1 g06320914 1. Remove bolts (1) and thrust plate (2). Remove cluster idler gear (3). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/4/24

w 5/7(W) Illustration 2 g06321115 2. Use Tooling (A) and a suitable press to remove sleeve bearing (4) from cluster idler gear (3). Illustration 3 g06321120 3. Remove bolts (5). 4. Remove idler shaft (6) with camshaft idler gears (7). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/4/24

Suggest: For more complete manuals. Please go to the home page. https://www.ebooklibonline.com If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

w 6/7(W) Illustration 4 g06321154 5. Remove thrust washers (8) from gears (7). Illustration 5 g06321151 6. Use Tooling (A) and a suitable press to remove sleeve bearing (9) from camshaft idler gears (7). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/4/24

w 7/7(W) Illustration 6 g06321167 7. Remove bolts (11). Remove cluster gear shaft (10). Illustration 7 g06321170 8. Remove bolts (12). Remove crankshaft gear (13). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/4/24

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com