Case IH LRZ 95 LRZ 100 LRZ 120 LRZ 130 LRZ 150 Loader Operator’s Manual Instant Download (Publication No.84265730)

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

ORIGINALINSTRUCTIONS - according to Directives 2006/42/EC, Annex I 1.7.4.1 LRZ 95 LRZ 100 LRZ 120 LRZ 130 LRZ 150 Loader Operator s Manual Print No. 84265730 1st edition English 01/10 CASE

TO THE OWNER ThismanualcontainsinformationconcerningtheadjustmentandmaintenanceofyourCaseModelFrontLoader. You have purchased a dependable machine, but only by proper care and operation can you expect to receive the performance and long service built into this loader. Please have all operators read this manual carefully and keep it available for ready reference. Obtain a new operating manual immediately if the old manual is damaged or lost. ThisloaderwasdesignedtobeusedwithJXU,MaxxumandPumaSWBtractors.Itisintendedtoloadandmove materials with a variety of buckets and attachments. Your authorised Case dealer will instruct you in the general operation of your loader. (Refer to the Delivery Report atthebackofthismanual.)Yourdealer sstaffoffactory-trainedservicetechnicianswillbegladtoanswer any questions that may arise regarding the operation of your loader. YourauthoriseddealercarriesacompletelineofgenuineCaseserviceparts.Thesepartsaremanufacturedand carefully inspected to insure high quality and accurate fitting of any necessary replacement parts. Be prepared togiveyourdealerthemodelandproductidentification numberoftheloader,whenorderingparts.Locatethese numbers now and record them below. Refer to the General Information and Safety section of this manual for the location of the model and product identification numbers of your loader. Note the front loader data here. In section 1 on page 1--1 there is a description of where the type plate of the front loader is located. Front loader Front loader model Production number Year of manufacture Delivery list number Purchase date Note the data here for the tractor to which the front loader has been attached. Tractor Tractor model Production number Year of manufacture PRODUCT IMPROVEMENTS Caseiscontinuallystrivingtoimproveitsproducts.Wereservetherighttomakeimprovementsorchangeswhen it becomes practical and possible to do so, without incurring any obligation to make changes or additions to the equipment sold previously.

EC Declaration of Conformity In accordance with the EC Machinery Directive 2006/42/EC, Annex II A The company, Wilhelm Stoll Maschinenfabrik GmbH Bahnhofstra e 21 38268 Lengede, Germany herby declares that the Case front loader, type NS, NS+, MS and MS+ satisfies the basic safety and health requirements set forth in the EC directive. Applied directives: 2006/42 EC (war 98/37/EC) 2004/108/EC (war 89/336/EEC) Machinery directive Electromagnetic compatibility Applied standards: EN 12525:2000, EN 12525/A1:2006 EN ISO 12100--1, --2:2003 Front loaders -- Safety Safety of machinery -- Basic concepts, general principles for design Safety of machinery -- hydraulic system Carries for attachments Electromagnetic compatibility EN 982:1996 ISO 23206:2005 EN ISO 14982:1998 Legende, 1 October 2007 pp Uwe Ockert Design Legende, 1 October 2007 pp Klaus Schlag Plant manager

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

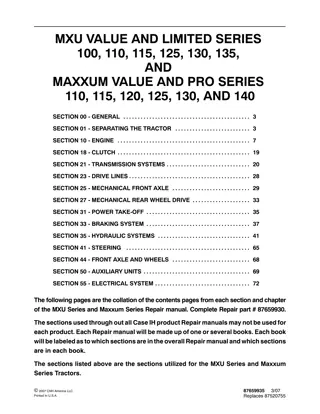

CONTENTS Title Page Section 1 - - General Information and Safety Identification Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Safety and Advisory Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ecology and the Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1--1 1--2 1--3 1--8 1--14 Section 2 - - Loader Operation General Information Loader and Loader Types Description Operation of the Front Loader Attaching the Loader Removing the Loader Varipark Parking Stands Installation and Removal of Attachments 3rd and 4th Hydraulic Control Circuits Setting Bucket Level Indicator Float Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Extra scooping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Active Extra--scooping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Drop Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fast Tip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Attachment Self Levelling Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic Control Valves, Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Smooth Ride Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ballasting the Tractor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Operating with the Loader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Special Attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2--1 2--4 2--8 2--13 2--16 2--18 2--20 2--23 2--26 2--27 2--27 2--28 2--28 2--28 2--29 2--30 2--32 2--33 2--34 2--37 Section 3 - - Lubrication and Maintenance Loader Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Loader Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Loader Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Checking Loader Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hardware Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tube and Fitting Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3--1 3--2 3--2 3--2 3--3 3--4 Section 4 - - Fault Finding Loader, General Multi Quick Coupler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4--1 4--7

Section 5 - - Specifications LRZ 95 NS, LRZ 95 NS+ LRZ 95 MS, LRZ 95 MS+ LRZ 100 NS, LRZ 100 NS+ LRZ 100 MS, LRZ 100 MS+ LRZ 120 NS, LRZ 120 NS+ LRZ 120 MS, LRZ 120 MS+ LRZ 130 NS, LRZ 130 NS+ LRZ 130 MS, LRZ 130 MS+ LRZ 150 MS, LRZ 150 MS+ Case LRZ Optional Loader Implement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5--3 5--4 5--5 5--6 5--7 5--8 5--9 5--10 5--11 5--12 Section 6 - - Circuit Diagrams Circuit Diagram -- Hydraulic System Circuit Diagram -- Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6--1 6--6 Section 7 - - Index Section 8 - - Delivery Report

Tractor- -loader combination Range JXU Tractor Front loader modell 75 R R R R - - - - - - - - - - - - - - - - 85 C C C C R R R R C C C C 95 - - - - - - - - R R R R C C C C 105 - - - - - - - - C C C C R R R R LRZ 95 NS LRZ 95 NS+ LRZ 95 MS LRZ 95 MS+ LRZ 100 NS LRZ 100 NS+ LRZ 100 MS LRZ 100 MS+ LRZ 120 NS LRZ 120 NS+ LRZ 120 MS LRZ 120 MS+ R = Recommended NS+ = Non Self Levelling C = Compatible MS+ = Mechanical Self Levelling - - = Non Compatible

Tractor- -loader combination Range Maxxum Tractor 130 C C C C R R R R - - - - Front loader modell 100 R R R R C C C C - - - - 110 R R R R C C C C - - - - 120 C C C C R R R R - - - - 115 - - - - - - - - R R R R - - - - 125 - - - - - - - - C C C C R R 140 - - - - - - - - - - - - - - - - C C LRZ 100 NS LRZ 100 NS+ LRZ 100 MS LRZ 100 MS+ LRZ 120 NS LRZ 120 NS+ LRZ 120 MS LRZ 120 MS+ LRZ 130 MS LRZ 130 MS+ R = Recommended NS+ = Non Self Levelling C = Compatible MS+ = Mechanical Self Levelling - - = Non Compatible

Tractor- -loader combination Range PUMA SWB Tractor T6070 C C C C C C Front loader modell T6030 C C C C R R T6080 - - - - - - - - - - - - LRZ 120 NS LRZ 120 NS+ LRZ 120 MS LRZ 120 MS+ LRZ 130 MS LRZ 130 MS+ R = Recommended NS+ = Non Self Levelling C = Compatible MS+ = Mechanical Self Levelling - - = Non Compatible

SECTION 1 GENERAL INFORMATION AND SAFETY The LRZ 95, LRZ100, LRZ 120, LRZ 130 and LRZ 150 front loaders are designed to be used with the Case JXU, Maxxum and Puma SWB range of tractors. A choice of optional buckets and attachments are available to make Case LRZ front loaders a genuine multi-purpose tool. As the capacities of the buckets have been matched to the tractor size, the operator can choose the bucket best suited for the tractor, as wellas thetask.Bucketsizes andrecommendations are listed in the Specifications section. A product identification plate is attached on the transverse pipe of the loader unit. For your convenience, have your dealer record the informa- tiononthisplateinthespaceprovidedonthe ToThe Owner page at the front of this manual. All data supplied in this book is subject to production variations.Dimensionsandweightsareapproximate only, and the illustrations do not necessarily depict tractorsorloadersinstandardcondition.Forspecific information about any tractor or loader, please consult your authorised dealer. 4 P.I.N. Plate Location The Product Identification Plate (1) is located on the transverse pipe of the loader unit. In addition, the production number has been stamped on the transverse pipe. This plate contains important informationontheloaderModelandSerialnumbers. Your authorised dealer will require this information when ordering parts or accessories for your loader. Data on the plate (see Figure 4): 1.) Front loader type 2.) Fabrication number 3.) Year of manufacture 4.) Weight of the front loader without implement 5.) Serial number 6.) Function code 5 NOTE: Make yourself aware of the legislative requirements in your country and pay attention to the national legislative approval of any kind of equipment firmly attached to the tractor. requirements for 1--1

SECTION 1 - - GENERAL INFORMATION AND SAFETY SAFETY PRECAUTIONS A careful operator is the best operator. Most accidents can be avoided by observing certain precautions. To help prevent accidents, read the following precautions before operating this equip- ment. Equipment should be operated only by those who are responsible and instructed to do so. Personal Safety CAUTION The word CAUTION is used where a safe behavioural practice, according to operating and maintenance instructions practices will protect the operator and others from accident involvement. and common safety Precautionary Statements Throughoutthismanualandonmachinedecals,you will find precautionary WARNING, CAUTION, NOTE, ATTENTION and IMPORTANT followed by specific instructions. statements DANGER, WARNING The word WARNING denotes a potential or hidden hazard which could possibly cause serious injury. It is used towarn operators and others to exercisedue care and attention to avoid a surprise accident with machinery. These precautions are intended for the personal safetyofyouandthoseworkingwithyou.Pleasetake the time to read them. Machine Safety DANGER The word DANGER denotes a forbidden practice in connection with a serious hazard. NOTE: This text stresses a correct operating technique or procedure. ATTENTION: This textwarns theoperator ofpotential machinedamageifacertainprocedureisnotfollowed. Failure to follow the CAUTION, WARNING and DANGER instructions may result in serious bodily injury or even death. IMPORTANT: This text informs the reader of something that he needs to know to prevent minor machine damage if a certain procedure is not followed. Carefully reviewtheprocedures giveninthismanual with all operators. It is important that all operators be familiar with and follow safety precautions. 1--2

SECTION 1 - - GENERAL INFORMATION AND SAFETY GENERAL INFORMATION 1. Read the Operator s manual completely and thoroughly before using the tractor or loader. Lack of operating knowledge can lead to serious accidents. The Tractor 1. Use approved rollover protection and seat belt for safe operation. Overturning a tractor without anapprovedcaborrollbarcouldresultinserious injury or death. If the tractor is not equipped with the proper rollover protection, see your tractor dealer to obtain the proper parts. 2. Operatethetractoronlyfromtheoperator sseat. The direction information right and left used in this operating manual is always based on the driver s perspective. 2. Always use the seat belt on tractors equipped with a roll bar or cab. Do not use a seat belt if operating the tractor without a roll bar or cab. 3. Replace damaged, missing or illegible safety decals. See the Safety and Advisory Decal section in this manual for proper location of all safety decals. 3. Add the recommended wheel ballast and/or rear weight as recommended in the Owners manual to provide adequate stability when using a loader. 4. Comply with the accident prevention regulations as well as the technical safety, occupational health, and road traffic regulations of the country where the front loader is used. 4. Positionthewheels tothetractormanufacturer s widest recommended stability. settings to increase 5. Unauthorized changes to the front loader and to theimplementsexcludeliabilityonthepartofthe manufacturer for resulting damage. 5. Move and turn the tractor at low speeds. When drivingoncurvesreducethespeedandlowerthe load. 6. Ensure that all components are firmly attached. 7. Repairorreplacedamaged,excessivelyworn,or missing parts. 6. Before starting the engine, be sure all operating controls are in the neutral or park position. This will eliminate accidental movement of the machine or start up of power driven equipment. 8. Regularly check the tightening torque of all bolts and nuts. Ensure that all components are lubricated regularly. See the Lubrication and Maintenance section in this manual. 7. Beforeleavingthetractor,stoptheengine,putall controls in neutral, engage the park brake, lower the front loader onto the ground and remove the key from the key switch. 9. Ensure that protective devices and covers are in good condition and properly mounted. 8. Whentransportingtheloader,engagetheloader control neutral lock to prevent accidental cycling of the loader. WARNING Connect the brake pedals of the tractor together. Never use separated brakes if a front loader is mounted. 1--3

SECTION 1 - - GENERAL INFORMATION AND SAFETY The Loader 1. Improperuseofaloadercancauseseriousinjury or death. 2. NEVERusetheloadertoliftorcarryanyonewith the bucket, frame or attachment. Serious injury or death could result from falling off the tractor or loader during transport or operation. 3. NEVER allow anyone to get under the loader bucket or reach through the lift arms when the bucket is in the raised position. 4. Donotwalkorworkunderaraisedloader,bucket or attachment unless it is securely blocked or held in position. Accidental movement of a control lever or a leak in the hydraulic system could cause the main frame to drop, or attachment to dump causing severe injury or death. 5. Makesurealldismountedloadersonparkstands areonahardlevelsurfacewithallsafetydevices engaged to prevent the parked loader from falling and being damaged or injuring someone. Only park the front loader with attached implement. 6. Do not repair, remove or replace any parts of the loader while in the dismounted, parked position. 7. Avoid overhead wires and obstacles when the loader is raised. Contacting overhead electrical lines can cause severe electrical burns or death from electrocution. Make clearance is available before raising the loader. certain sufficient 8. Constantly observe your work area. Ensure that people or animals do not obstruct the work area. 1--4

SECTION 1 - - GENERAL INFORMATION AND SAFETY OPERATING THE LOADER 1. The equipment owner is responsible to make certain that all operators read this manual thoroughly and understand the safety precau- tions and proper operating procedures. Be certainalloperatorsarequalifiedbeforeallowing operation. used.Handlingsuchobjectsisnotrecommended without special equipment. 12. Handling large heavy objects can be dangerous due to the following: danger of overturning the tractor 2. Always underground utilities before digging. check with proper authorities for danger of upending the tractor 3. Exercise caution when operating the loader with a raised bucket or attachment. danger of the object rolling or sliding down the loader arms onto the operator 4. Avoid loose fill, rocks and holes. These are dangerous conditions for loader operation or transport. 13. If the type of work in precaution 12 must be performed, adhere to the following: always use the proper attachment 5. Use caution when operating on steep grades. Always carry the bucket or attachment in the lowest possible position to maintain maximum stability. Select the attempting to travel on a steep grade. Avoid shifting on grades and never free wheel . Push the load material together downhill. Scoop up the material in the depression at the bottom of the incline. never lift the load higher than necessary to clear the ground while moving proper gear BEFORE ballast the rear of the tractor to compensate for the weight of the load never lift large or heavy objects with equipment that does anti-rollback device not have an 6. Besuretoallowforthelengthoftheloaderwhen making turns or working in confined areas. 7. Stop the loader arms gradually when raising or lowering the loader. move slowly and carefully, avoiding rough or uneven terrain 8. Carry the bucket or attachment as low as possible to increase visibility during transport. 14. Loader lift capacity and break-away capacity diminish as the loader height is increased. Use care not to grasp more material than the loader is designed to handle. 9. When parked or during servicing of the loader, lower the bucket to the ground, stop the engine, set the park brake and remove the key from the key switch. Special care should be taken to park or store attachments with sharp points or edges in a safe manner. 15. Tractor and front loader work with hydraulic oil that is under high pressure in operation. Check allhydraulic components and keepthem ingood condition. Ensure that hydraulic components -- particularly hoses -- cannot be damaged by moving parts. 10. Do not operate loader controls unless properly seated in the operator s seat. 11. NEVER attempt to handle large, heavy objects such as large round or rectangle bales, logs or oil drumsunlessthespecificspecialattachmentsare 16. Only execute front loader work if the visibility conditions are adequate. Ensure that the work area is adequately illuminated. Keep the cab windshield clean. 1--5

SECTION 1 - - GENERAL INFORMATION AND SAFETY 17. Do not drive the tractor in a jerky manner if the front loader is in the highest load position and fully loaded. 19. Neverstackmultipleloads(bales,pallets)ontop of each other. The upper loads can fall on you. Special implements, such as baling implements orpalletforksaredesignedinsuchamannerthat they prevent loads from falling onto the tractor. 18. Check the implement tilt when lifting the front loader. Raised loads can fall on you if you scoop the implement too far. When lifting NS and NS+ front loaders you must compensate for the angular increase of the implement by dumping the implement. 20. When levelling do not drive faster than 10 km/h. In this process tilt the implement a maximum of 45 . 21. Switchoffthefrontaxlesuspensionofthetractor. 1--6

SECTION 1 - - GENERAL INFORMATION AND SAFETY MAINTENANCE 1. Alwaysweareyeprotection,protectivecoveralls, gloves, safety footwear when servicing or repairing the loader. if any fluid is injected into the skin, obtain medical attention IMMEDIATELY to avoid the onset of Gangrene 2. Do not modify, alter or permit anyone else to modify or alter the loader or any of it s components or functions without first consulting your dealer. Contact your dealer with questions about the loader. 4. DO NOT tamper with or change the relief valve settings. The relief valve is preset at the manufacturer for optimum performance and safety. Changing the settings may cause overloading of the tractor hydraulic system resulting in equipment failure and/or serious operator injury. 3. Escaping hydraulic fluid under pressure can penetrate the skin causing serious injury. To prevent serious personal injury: DO NOT use your hand to check for suspected leaks under pressure 5. When servicing or replacing the pins in the cylinder ends, bucket, etc., always use a brass drift. Failure to do so could result in equipment damage and/or personal injury due to flying metal fragments. use a piece of cardboard or heavy paper to search for leaks 6. Lowerthefrontloaderontotheground.Leavethe front loader coupled to the tractor. Let the machine temperature cool to below 55 C. Ensure good lighting. stop the engine and relieve the pressure in the system before disconnecting hydraulic lines and fittings connecting or 7. NEVER stand between the front of the tractor andthetransversepipeofthefrontloader.Never repair the front loader with raised front loader. Lower the front loader onto the ground. tightenalllinesandfittingsbeforestartingthe engine and pressurizing the system 1--7

SECTION 1 - - GENERAL INFORMATION AND SAFETY SAFETY AND ADVISORY DECALS The following decals have been placed on your machine in the areas indicated. They are intended for your personal safety and for those working with you. Please take this manual and walk around your machine to note the content and location of these warning signs. Review these warning signs and the operating instructions detailed in this manual with your machine operators. Keepthedecalslegible.Iftheyarenot,obtainreplacementsfromyourauthoriseddealer.Thedecalreplacement part numbers and location reference are listed with each decal. Right- -Hand Side 6 1. Loader Arm Installation and Removal When installing or removing the loader arms, follow these instructions. Decal Part Number: 87690032 Location: Right--hand loader pillar. WARNING Readandunderstandallthewarningnotesprintedin this operators manual. 7 1--8

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

SECTION 1 - - GENERAL INFORMATION AND SAFETY 2. Bystanders DANGER Do not permit bystanders to enter the working area of the loader. Should any person enter the working area, STOP the tractor and lower the bucket or attachment to the ground. Decal Part Number: 87689888 Location: Rear of right--hand loader arm. 8 3. Lifting Point If it is required to lift the loader arm assembly using a crane or other lifting device, attach the straps or chains at this point. Decal Part Number: 87690032 Location: Centre of right--hand loader arm. 9 4. Driver safety WARNING Readandunderstandallthewarningnotesprintedin the operators manual. Decal Part Number: 87689902 Location: In the cabin. 10 1--9

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com