Case IH Improved Cooling System for Farmall and International 400 and 500 Diesel Tractors Operator’s Manual Instant Download (Publication No.1014239R1)

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Improved Cooling system for Farmall and International 400 and 500 Diesel Operator's Manual 1014239R1

it THIS SAFETY ALERT SYMBOL INDICATES IMPORTANT SAFETY MESSAGES IN THIS MANUAL. WHEN YOU SEE THIS SYMBOL, , CAREFULL Y READ THE MESSAGE THAT FOLLOWS AND BE ALERT TO THE POSSIBILITY OF PERSONAL INJURY OR DEA TH. M171B If Safety Decals on this machine use the words Danger, Warning or Caution, which are defined as follows: DANGER: Indicates an immediate hazardous situation which if not avoided, will result in death or serious injury. The color associated with Danger is RED. WARNING: Indicates an potentially hazardous situation which if not avoided, will result in serious injury. The color associated with Warning is ORANGE. CAUTION: Indicates an potentially hazardous situation which if not avoided, may result in minor or moderate injury. It may also be used to alert against unsafe practices. The color associated with Caution is YELLOW. If Safety Decals on this machine are ISO two panel Pictorial, decals are defined as follows: The first panel indicates the nature of the hazard. The second panel indicates the appropriate avoidance of the hazard. Background color is YELLOW. '" it WARNING IMPROPER OPERATION OF THIS MACHINE CAN CAUSE INJURY OR DEATH. BEFORE USING THIS MACHINE, MAKE CERTAIN THAT EVERY OPERATOR: Prohibition symbols such as \.Y X and 8 if used, are RED. Is instructed in safe and proper use of the machine. Reads and understands the Manual(s) pertaining to the machine. Reads and understands ALL Safety Decals on the machine. Clears the area of other persons. Learns and practices safe use of machine controls in a safe, clear area before operating this machine on a job site. It is your responsibility to observe pertinent laws and regulations and follow Case Corporation instructions on machine operation and maintenance. Bur 0-00000 2001 Case Corporation issued November, 1994 CASE and IH are registered trademarks of Case Corporation

INSTALLING INST.UONQMS PARTS LIST ~ HI. HARVESTER INTERN ... TtONAl Improved Cooling System (376 390 R91) for McCORMICK FARMALL and INTERNATIONAL 400 Diesel and 450 Diesel Tractors ,

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

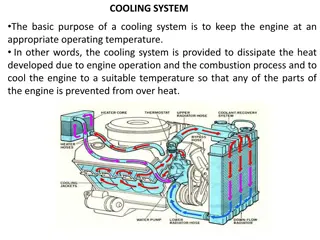

It is the policy of International Harvester Company to im- p:rove its products whenever it i s possible and practical to do sa. We reserve the right to make changes or add improve- r.x:?-ents at any time without incurring any obligation to make such changes on products sold previously. All illustrations and descriptive matter in this publication aVply to International Harvester products sold under the Ipternational, McCormick, McCormick-International , )'ov'lcCormick-Deering. or McCormick-Deering International trade name. ORDERING NUMBER Improved cooling system 376390 R91 This improved cooling system is for the following "Diesel" 'engine tractors: Farmall 400 Diesel, 400 Diesel Hi-Clear, 450 Diesel, 450 Diesel Hi-Glear, and International 400 Diesel, aod 450 Diesel Tractors. INTRODUCTION The auxiliary cooling tank referred to as a "surge tank" allows space for the expansion of the coolant under conditions of excessive heat and heavy-duty operation . The improved cooling system consists principally of an auxiliary cooling tank and related parts nece5S< l.ry for complete instal- lation. OPERATION If opening pressure of the cap is le s s than four pounds, loss of coolant and overheating can result. The auxiliary cooling tank ()verflow pressure valve is located in the cap. The cap gasket must always be in good condition to maintain the pressure. Refer to your tractor Operator's Manual for additional cooling sys- tem information. FILLING THE SYSTEM Cold Engine: Fill the radiator to the top. Do not put coolant in the auxiliary cooling tank. Hot Engine: Fill the radiator to the top and put 1-1/2 pints of coolant in the auxiliary cooling tank . caUtiOnl Always remove the auxiliary cool- ing tank cap before removing the radiator cap. Turn the pressure type cap counter- clockwise to the safety stop to allow the pres- sure or any steam to escape; then press dov-m on the cap and continue to turn until the cap is free to be removed from the auxiliary cooling tank. Then remove the radiator cap. ~ Shut Down Procedure and Coolont Levels . There can be a loss of water due to "after boil" or heat surge. When an engine is run under load, the whole mass of iron becornes heated, then, if the engine is suddenly shut- down. the stored heat in the iron is transferred to the coolant which causes Itafter boil", To avoid "after boU" or heat surge, the engine should be operated at low speed for a minimum of three minutes before shut-down, this will more effectively control the dissipation of the heat accumulated in the engine. The system must be free of air. Coolant level should be checked during the engine warm up period after the initial fil.L Coolant should be added until the level stabllzes after the engine has reached operating te mperature. Pre s sure in the system should be maintained at approximately four pounds. 2