Automotive Carbon Thermoplastic Market

The automotive carbon thermoplastic market was valued at $288.2 million in 2023, and it is expected to grow at a CAGR of 23.22% and reach $2,325.6 million by 2033.nnRead Report Overview: //bisresearch.com/industry-report/automotive-carbon-therm

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

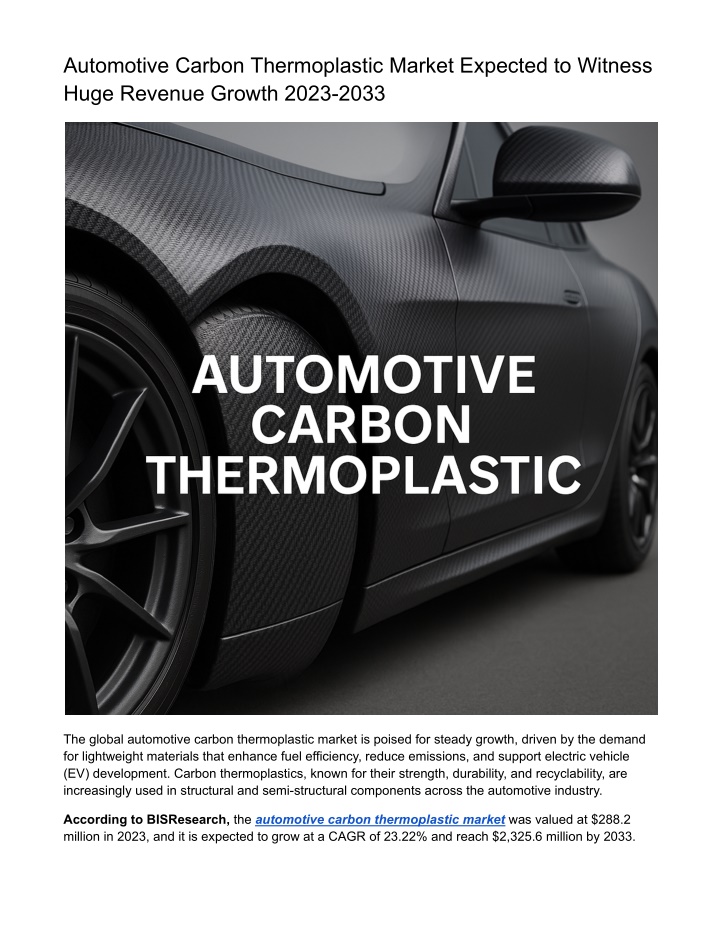

Automotive Carbon Thermoplastic Market Expected to Witness Huge Revenue Growth 2023-2033 The global automotive carbon thermoplastic market is poised for steady growth, driven by the demand for lightweight materials that enhance fuel efficiency, reduce emissions, and support electric vehicle (EV) development. Carbon thermoplastics, known for their strength, durability, and recyclability, are increasingly used in structural and semi-structural components across the automotive industry. According to BISResearch, the automotive carbon thermoplastic market was valued at $288.2 million in 2023, and it is expected to grow at a CAGR of 23.22% and reach $2,325.6 million by 2033.

This growth is underpinned by regulatory mandates for fuel economy, rising adoption of EVs, and technological advancements in composite manufacturing. Recent Developments in the Automotive Carbon Thermoplastic Market In October 2023, Celanese Corporation introduced new sustainable engineering thermoplastic solutions, which are aimed at supporting manufacturers in their transition to a circular economy. These innovative materials, known as ECO-R, offer outstanding mechanical properties and other benefits while incorporating recycled content. In December 2022, Asahi Kasei Corporation collaborated with the National Institute of Technology, Kitakyushu College, and Tokyo University of Science to develop fundamental technology for recycling continuous carbon fiber. In October 2022, Avient Corporation introduced reSound Ultra-Low Carbon Footprint TPEs, which offered an industry-first cradle-to-gate product carbon footprint (PCF) range between -0.46 and -0.02 in kg CO2 equivalent kg/ product. In September 2021, Solvay announced the completion of its new thermoplastic composites (TPC) manufacturing plant located at its Greenville, South Carolina site, with a full production capacity of 27,000 square feet. In Feb 2021, BASF SE expanded its polyphthalamide (PPA) portfolio of Ultramid advanced with carbon-fiber reinforced grades with fillings of 20, 30, and 40 percent. The new carbon-fiber (CF) reinforced grades can be used to manufacture automotive structural parts for the body, chassis and powertrain, pumps, fans, gears, and compressors in industrial applications, as well as for stable and ultra-lightweight components in consumer electronics. Request A Free Sampleon the Dural Adhesive Agent for Surgical Market! Key Drivers in the Automotive Carbon Thermoplastic Market The automotive sector is undergoing a major shift toward sustainability, with manufacturers increasingly incorporating environmentally friendly materials into their production lines. There is growing interest in using recycled content, bio-based thermoplastics, and alternatives to conventional plastics, reflecting the industry's broader commitment to reducing environmental impact. A notable example is the January 2022 partnership between Mercedes-Benz and UBQ Materials a company that produces innovative thermoplastics from landfill-destined waste. In its all-electric VISION EQXX concept car, Mercedes-Benz integrated UBQ s sustainable thermoplastic in key areas such as the body shell and interior structures, including headrests. By choosing UBQ s bio-based material over traditional petroleum-based plastics, Mercedes-Benz has taken a meaningful step toward enhancing the vehicle s overall sustainability. UBQ was also incorporated into the car s bionic structural components, further showcasing its versatility and eco-conscious value. Automotive Carbon Thermoplastic Market by Region: Europe leads the automotive carbon thermoplastic market due to strict emission norms, a focus on lightweight design, and strong manufacturing capabilities in countries like Germany and France. Robust R&D infrastructure, government support for sustainable mobility, and collaboration between OEMs and material suppliers are driving the adoption of carbon thermoplastics for improved efficiency and reduced emissions.

Some of the prominent names in the market are: Avient Corporation Asahi Kasei Corporation BASF SE Celanese Corporation COMPLAM Material Co., Ltd. Solvay DuPont Mitsubishi Chemical Group Corporation SABIC SGL Carbon TEIJIN LIMITED DowAksa Hexcel Corporation Covestro AG TORAY INDUSTRIES, INC. Download Our ToC: Click Here! Future Outlook The automotive carbon thermoplastic market is set for robust expansion as OEMs and suppliers continue to invest in lightweight, sustainable, and high-performance materials. Innovations in hybrid composites, 3D printing, and thermoplastic resin systems will further open new opportunities in next-generation vehicle design.