Advanced AR Technology for Industrial Maintenance

Augmented reality technology is utilized in this project to develop devices that project images onto workpieces to aid operators in performing tasks efficiently. The project aims to enhance assembly processes through pattern recognition algorithms and interactive guidance using AR technology.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

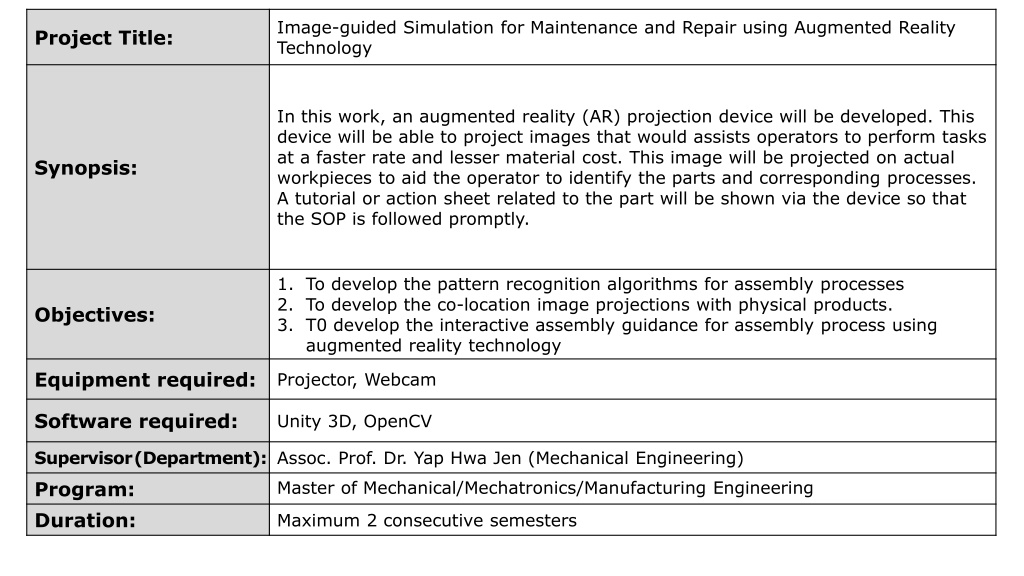

Image-guided Simulation for Maintenance and Repair using Augmented Reality Technology Project Title: In this work, an augmented reality (AR) projection device will be developed. This device will be able to project images that would assists operators to perform tasks at a faster rate and lesser material cost. This image will be projected on actual workpieces to aid the operator to identify the parts and corresponding processes. A tutorial or action sheet related to the part will be shown via the device so that the SOP is followed promptly. Synopsis: 1. To develop the pattern recognition algorithms for assembly processes 2. To develop the co-location image projections with physical products. 3. T0 develop the interactive assembly guidance for assembly process using augmented reality technology Objectives: Equipment required: Projector, Webcam Software required: Unity 3D, OpenCV Supervisor(Department): Assoc. Prof. Dr. Yap Hwa Jen (Mechanical Engineering) Program: Master of Mechanical/Mechatronics/Manufacturing Engineering Duration: Maximum 2 consecutive semesters

Design & Development of a Real-time Motion Capture and Simulation for Upper Body Ergonomics Assessment Project Title: The idea of the project is to capture the motion of the upper body of the workers while performing a task. The Avatar will be used to simulate his/her motion in real-time using virtual reality technology and the motion data will be assessed to identify potential awful postures/motions. The users can see themselves virtually (Avatar) and they will be alarmed by the indicator in the virtual environment if their posture is incorrect. It is expected that the user can learn the correct posture immediately in the virtual environment. Synopsis: 1. To develop the calibration method for the sensors location recognition 2. To integrate the VR-tracker with the virtual human model (avatar) 3. To identify the awful posture of the user using virtual reality technology Objectives: Equipment required: Vive tracker, Head-mounted Display Software required: Unity 3D, SteamVR Supervisor(Department): Assoc. Prof. Dr. Yap Hwa Jen (Mechanical Engineering) Program: Master of Mechanical/Mechatronics/Manufacturing Engineering Duration: Maximum 2 consecutive semesters

Design and development of a 3-DOF motion platform for Virtual Reality-based Balancing Training Simulator Project Title: This project is aimed to design & develop a 3-DOF (degree-of-freedom) motion platform for Virtual Reality-based Balancing Training Simulator. The 3-DOF platform should be designed to facilitate practice and identify the key benefits in motivating and engaging users to effectively learn the balancing skills correctly and safely. By blending into the VR-based training, it is expected that the motivation and satisfaction of the users can be improved compared to the conventional training method. Synopsis: 1. To identify the importance of balancing training for the rehabilitation. 2. To design a 3-DOF motion platform for balancing training purposes. 3. To integrate the 3-DOF motion platform into the VR-based balancing training simulator Objectives: Equipment required: Head-mounted Display (HMD) Software required: Unity 3D, SteamVR, Arduino IDE Supervisor(Department): Assoc. Prof. Dr. Yap Hwa Jen (Mechanical Engineering) Program: Master of Mechanical/Mechatronics/Manufacturing Engineering Duration: Maximum 2 consecutive semesters

Project Title: Design and development of an image-guided vision system for robotics palletizing In this project, the student needs to design and develop an image-guided vision system using Raspberry-Pi with OpenCV. The vision system should be able to identify the product with non-uniform shapes (eg drumstick vs wings), and guide the robotics arm to pick the product in the correct orientation and place at the related pallet. Synopsis: 1. To develop an algorithm to identify the product with non-uniform shapes. 2. To identify the orientation of the products for end-effector picking/grasping. 3. To integrate the vision system with a robotics arm for the palletizing process. Objectives: Equipment required: Kuka Robot, PLC Software required: RoboDK, OpenCV Supervisor(Department): Assoc. Prof. Dr. Yap Hwa Jen (Mechanical Engineering) Program: Master of Mechanical/Mechatronics/Manufacturing Engineering Duration: Maximum 2 consecutive semesters