Mirai Botnet

The Mirai Botnet, created by Maneth Balasooriya and Jacob Gottschalk, is a notorious IoT botnet known for Distributed Denial-of-Service attacks on devices like IP cameras and DVRs. It originated from a Minecraft server protection racket and has been involved in major incidents. The botnet operates v

2 views • 8 slides

Insights into Workplace Assessment Process at Asco Motors

Asco Motors prioritizes safety above all else, ensuring a secure working environment through policies, compliance, and safety measures. Their industry engagement focuses on providing top-quality Toyota cars and exceptional after-sales services. The workplace processes include a system to monitor tec

0 views • 10 slides

Lean Manufacturing: Introduction, Philosophy, History, and Practices

Lean manufacturing is a strategic approach focused on continuous improvement by eliminating waste in processes. The philosophy originated from Henry Ford's assembly line and further developed by Toyota with the Toyota Production System. This content explores the core principles, history, and key dif

1 views • 6 slides

Lean Mistake-Proofing in Toyota Production Systems

Discover the principles of Lean Mistake-Proofing as applied in Toyota Production Systems. Learn about identifying and eliminating waste, different types of waste, mistake-proofing methods, and the importance of 5S methodology in preventing errors. Explore how Standard Operating Procedures play a key

0 views • 10 slides

Toyota Rail Strategy: Operations Guide for Vehicle Maintenance

This guide provides instructions for jump-starting vehicles with dead batteries, charging batteries, and refueling. It emphasizes using the correct procedures and equipment to avoid damage to Toyota vehicles. Follow these guidelines for safe and proper maintenance at any destination holding Toyota p

0 views • 5 slides

Teams and Leadership in Toyota Production Systems Lab

Explore key concepts of groups and teams, leadership styles, and team dynamics in the Toyota Production Systems Lab. Topics include group characterization, roles and norms, cohesiveness, interdependence, and maturity levels. Gain insights into effective team structures and strategies for achieving g

0 views • 11 slides

Sustainable Business Strategy Immersion Program in Japan

Explore the Sustainable Business Strategy Immersion Program in Japan, a 5-day program focused on sustainable business strategies. Meet with executives of Toray Industries, visit Toyota Factory in Nagoya, learn the art of tea-making in Kyoto, and delve into environmental sustainability at Houshi Ryok

1 views • 11 slides

Toyota Bulletin System User Guide

Guide on how to write and launch bulletins using the Toyota bulletin system including instructions on manual and automated metadata entry, selecting brands and models, and managing bulletin details. Users can access the bulletin application through Techdoc 3 and follow step-by-step instructions for

0 views • 9 slides

Hydrogen Fuel Cell Vehicle Winter Testing in Poland

Poland, a major hydrogen producer in Europe, conducts operational tests of hydrogen fuel cell vehicles in winter conditions to ensure safety and efficiency. The tests, conducted on a Toyota Mirai car equipped with fuel cells, focus on operational safety at temperatures as low as -25 degrees Celsius.

0 views • 14 slides

Toyota TEA15 Electric Powered Towing Tractor Service Repair Manual Instant Download

Toyota TEA15 Electric Powered Towing Tractor Service Repair Manual Instant Download

0 views • 21 slides

Toyota 2SGK6 2SDK6 2SDK7 2SDK8 Skid Steer Loader Service Repair Manual Instant Download

Toyota 2SGK6 2SDK6 2SDK7 2SDK8 Skid Steer Loader Service Repair Manual Instant Download

0 views • 22 slides

Toyota 5FBC13-30 Battery Forklift Service Repair Manual Instant Download

Toyota 5FBC13-30 Battery Forklift Service Repair Manual Instant Download

0 views • 30 slides

Toyota 5FGC10-15 Series Forklift Service Repair Manual Instant Download

Toyota 5FGC10-15 Series Forklift Service Repair Manual Instant Download

0 views • 26 slides

Toyota 6BWC101520 6BWS111520 6BWR15 Electric Walkie High Lifter Trucks Service Repair Manual Instant Download

Toyota 6BWC101520 6BWS111520 6BWR15 Electric Walkie High Lifter Trucks Service Repair Manual Instant Download

0 views • 26 slides

Toyota 6BWS10 6BWS13 Electric Walkie Adjustable Straddle Stacker Service Repair Manual Instant Download

Toyota 6BWS10 6BWS13 Electric Walkie Adjustable Straddle Stacker Service Repair Manual Instant Download

0 views • 23 slides

Toyota 6HBW20 4000LB Powered Pallet Walkie Service Repair Manual Instant Download

Toyota 6HBW20 4000LB Powered Pallet Walkie Service Repair Manual Instant Download

0 views • 24 slides

Toyota 6HBW20 Electric Pallet Jack Walkie Walk Service Repair Manual Instant Download

Toyota 6HBW20 Electric Pallet Jack Walkie Walk Service Repair Manual Instant Download

0 views • 20 slides

Toyota 6HBW23 Electric Walkie Pallet Jack Service Repair Manual Instant Download

Toyota 6HBW23 Electric Walkie Pallet Jack Service Repair Manual Instant Download

0 views • 24 slides

TOYOTA 7BPUE15 High Level Orderpicker Service Repair Manual Instant Download

TOYOTA 7BPUE15 High Level Orderpicker Service Repair Manual Instant Download

0 views • 23 slides

TOYOTA 7BRU18, 7BRU23, 7BDRU15, 7BSU20, 7BSU25 Reach Lift Truck Service Repair Manual Instant Download

TOYOTA 7BRU18, 7BRU23, 7BDRU15, 7BSU20, 7BSU25 Reach Lift Truck Service Repair Manual Instant Download

0 views • 27 slides

Toyota 7BWS10 7BWS13 Electric Walkie Low-Lift Pallet Truck Service Repair Manual Instant Download

Toyota 7BWS10 7BWS13 Electric Walkie Low-Lift Pallet Truck Service Repair Manual Instant Download

0 views • 24 slides

Toyota 7FBEF15 7FBEF16 7FBEF18 7FBEF20 Electric Forklift Trucks Service Repair Manual Instant Download

Toyota 7FBEF15 7FBEF16 7FBEF18 7FBEF20 Electric Forklift Trucks Service Repair Manual Instant Download

0 views • 21 slides

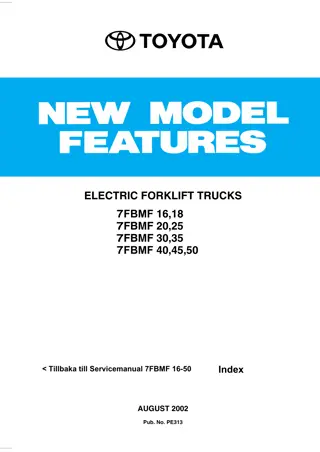

Toyota 7FBMF 16,18,20,25,30,35,40,45,50 Electric Forklift Trucks Service Repair Manual Instant Download

Toyota 7FBMF 16,18,20,25,30,35,40,45,50 Electric Forklift Trucks Service Repair Manual Instant Download

0 views • 25 slides

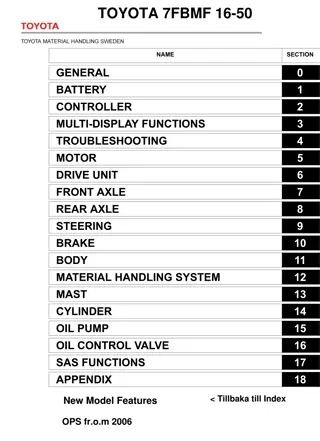

TOYOTA 7FBMF 16-50 Forklift Service Repair Manual Instant Download

TOYOTA 7FBMF 16-50 Forklift Service Repair Manual Instant Download

0 views • 25 slides

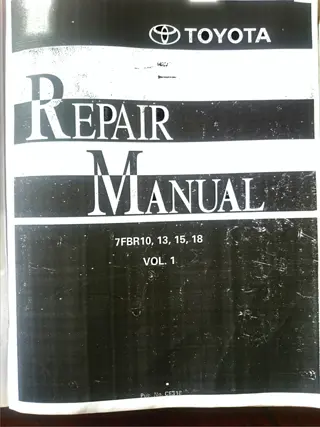

Toyota 7FBR10, 7FBR13, 7FBR15, 7FBR18 Forklift Service Repair Manual Instant Download

Toyota 7FBR10, 7FBR13, 7FBR15, 7FBR18 Forklift Service Repair Manual Instant Download

0 views • 24 slides

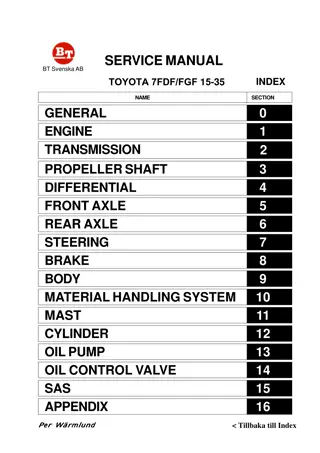

TOYOTA 7FDFFGF 15-35 Forklift Service Repair Manual Instant Download

TOYOTA 7FDFFGF 15-35 Forklift Service Repair Manual Instant Download

0 views • 24 slides

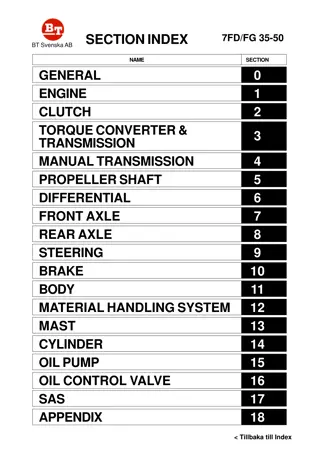

TOYOTA 7FDFG 35-50 Forklift Service Repair Manual Instant Download

TOYOTA 7FDFG 35-50 Forklift Service Repair Manual Instant Download

0 views • 27 slides

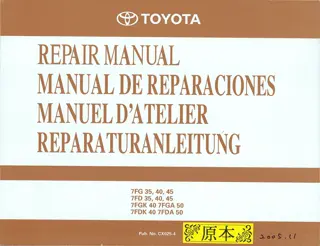

TOYOTA 7FG35, 40, 45 7FD35, 40, 45 7FGK40 7FGA50 7FDK40 7FDA50 Forklift Service Repair Manual Instant Download

TOYOTA 7FG35, 40, 45 7FD35, 40, 45 7FGK40 7FGA50 7FDK40 7FDA50 Forklift Service Repair Manual Instant Download

0 views • 31 slides

TOYOTA 7FGU7FDU15 - 32 series and 7FGCU20 - 32 series Forklift Service Repair Manual Instant Download

TOYOTA 7FGU7FDU15 - 32 series and 7FGCU20 - 32 series Forklift Service Repair Manual Instant Download

0 views • 26 slides

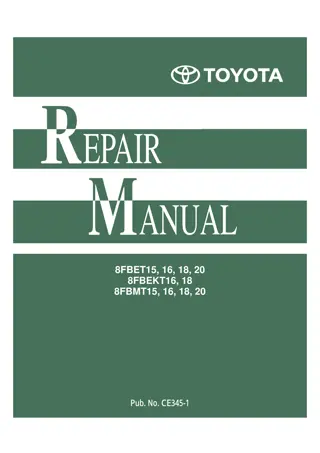

TOYOTA 8FBET15, 16, 18, 20 8FBEKT16, 18 8FBMT15, 16, 18, 20 Forklift Service Repair Manual Instant Download

TOYOTA 8FBET15, 16, 18, 20 8FBEKT16, 18 8FBMT15, 16, 18, 20 Forklift Service Repair Manual Instant Download

0 views • 24 slides

Toyota 42-7FGF15,18,20,25 02-7FGF30 02-7FDF15,18,20,25,30 62-7FDF20,25,30 02-7FGJF35 02-7FDJF35 Forklift Service Repair Manual Instant Download

Toyota 42-7FGF15,18,20,25 02-7FGF30 02-7FDF15,18,20,25,30 62-7FDF20,25,30 02-7FGJF35 02-7FDJF35 Forklift Service Repair Manual Instant Download

0 views • 23 slides

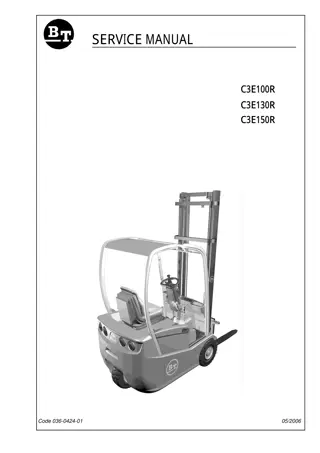

TOYOTA BT C3E100R C3E130R C3E150R Forklift Service Repair Manual Instant Download

TOYOTA BT C3E100R C3E130R C3E150R Forklift Service Repair Manual Instant Download

0 views • 24 slides

TOYOTA BT SWE140S SWE145 SWE145L SWE160 SWE160L SWE200 SWE200L Powered Stacker Forklift Service Repair Manual Instant Download

TOYOTA BT SWE140S SWE145 SWE145L SWE160 SWE160L SWE200 SWE200L Powered Stacker Forklift Service Repair Manual Instant Download

0 views • 26 slides

Toyota CBT4, CBT6, CBTY4 ELECTRIC POWERED TOWING TRACTOR Service Repair Manual Instant Download

Toyota CBT4, CBT6, CBTY4 ELECTRIC POWERED TOWING TRACTOR Service Repair Manual Instant Download

0 views • 22 slides

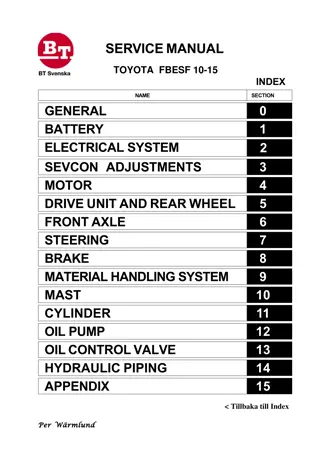

TOYOTA FBESF10 FBESF12 FBESF15 Forklift Service Repair Manual Instant Download

TOYOTA FBESF10 FBESF12 FBESF15 Forklift Service Repair Manual Instant Download

0 views • 20 slides

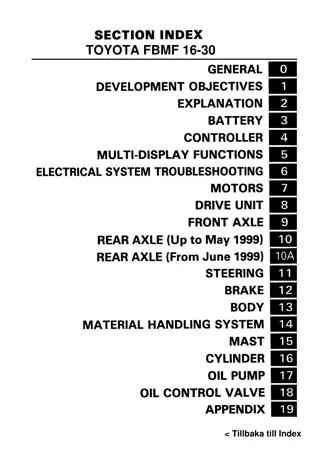

TOYOTA FBMF16 FBMF20 FBMF25 FBMF30 Forklift Service Repair Manual Instant Download

TOYOTA FBMF16 FBMF20 FBMF25 FBMF30 Forklift Service Repair Manual Instant Download

0 views • 26 slides

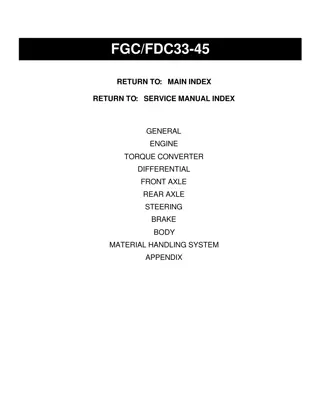

Toyota FDC33 FGC33 FDC35 FGC35 FDC40 FGC40 FDC45 FGC45 Forklift Service Repair Manual Instant Download

Toyota FDC33 FGC33 FDC35 FGC35 FDC40 FGC40 FDC45 FGC45 Forklift Service Repair Manual Instant Download

0 views • 25 slides

Toyota Forklift Engine 1DZ-II Model Service Repair Manual Instant Download

Toyota Forklift Engine 1DZ-II Model Service Repair Manual Instant Download

0 views • 23 slides

Toyota SDK10 Skid Steer Loader Service Repair Manual Instant Download

Toyota SDK10 Skid Steer Loader Service Repair Manual Instant Download

0 views • 24 slides

Muddiest Point: Questions on RSA, DDoS Attacks, and Block Cipher Algorithms

In this collection of images, various concepts related to RSA encryption, DDoS attacks, block cipher algorithms like DES and AES, TCP protocols, and real-life applications of cryptography are explored. The images cover topics such as the Mirai-infected devices used in a DDoS attack on Dyn, differenc

0 views • 14 slides